Photo courtesy Julie Bayer/David Chipperfield Architects

Tom Heffernan, the principal in charge of the project for Gensler, noted the request for proposals (RFP) issued by the university suggested tilt-up concrete construction as a good means of addressing the project requirements with its budget limitations and aggressive schedule.

“The team took this to heart and focused efforts on developing a tilt-up design that expressed the sculptural potential of site cast concrete,” he said. “UCSD and its surrounding community have a rich history of traditional cast-in-place concrete and we welcomed the challenge to use tilt-up methodology in an innovative way to design a new building that could hold its own among the other buildings on campus.”

Heffernan noted while speed was an important factor in the decision, there was more involved. The decision to use tilt-up concrete construction ultimately came down to the fact the method was able to provide a higher level of value to the university. Given a detailed RFP, a fixed budget, and straightforward campus requirements, C.W. Driver (general contractor) was able to estimate the costs of the interiors as well as the mechanical, electrical, and plumbing (MEP) systems with a high level of accuracy. What remained were the funds available for the skin, or façade, and structure.

“Within this budget, we could provide a conventional steel-framed building, but would only have enough budget left for a stucco or other low-cost cladding system,” explained Heffernan. “With the ‘triple-duty’ tilt-up system—cladding, lateral, and gravity system in one—we could provide a much higher level of quality to the university. A durable system with low maintenance requirements and, equally important, a system that afforded us powerful design opportunities.”

Building art

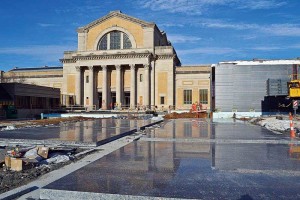

UCSD’s team is not alone in realizing tilt-up’s potential in offering speed, economy, and design opportunities. However, in many ways, the Saint Louis Art Museum (SLAM) was in an opposite position, and still opted for the construction method. In this case, the museum had plenty of money and time. Why they chose to build with tilt-up had everything to do with the quality of construction they were looking for, the aesthetic they desired, as well as the monumental scale they had in mind.

The Saint Louis Art Museum, located in Forest Park, Missouri, is situated atop Art Hill overlooking the Grand Basin—the central gathering place for the 1904 World’s Fair. Designed by renowned American architect Cass Gilbert for the 1904 Louisiana Purchase Exposition, the museum’s original structure was the only building from the fair designed to be permanent. The building has undergone several modifications and various additions, with the latest meant to result in a more uniform look, providing modern accessibility and expanded capabilities.

- The 18,580-m2 (200,000-sf) addition, designed by London architect David Chipperfield, provides for:

- new gallery space;

- fully accessible entrance;

- public space;

- restaurant overlooking Art Hill; and

- more than 300 parking spaces in a below-grade garage.

While fairly large, the addition has a relatively subtle exterior appearance. The above-grade, visible, portion of the building consists of large, clean expanses of glass and monumental planes of highly polished black concrete. Tilt-up was chosen because the methodology presented a unique opportunity to craft something ‘special’ that could not be done as efficiently or economically in any other way.

From the beginning, the design team desired a dark, monolithic concrete façade. With tilt-up, there was an opportunity to polish the panels horizontally, achieving a much higher-quality finish. Twenty-three panels were formed, cast, and finished on casting beds surrounding the structure. The 6.7-m (22-ft) tall panels range in width from 3.7 to 12.8 m (12 to 42 ft).