Understanding mass timber

Before talking about tall wood buildings, it is important to first clarify some misconceptions about mass timber, particularly with regard to fire safety and building codes. David Barber, principal at Arup, explains mass timber quickly forms a protective char layer in the event of a fire, and actually holds up longer than unprotected steel in some fire tests. The beauty of mass timber is it can serve as a finish material while providing the required fire-resistance rating. Wood also burns much more predictably than concrete, and the required thickness (generally 19 mm [¾ in.] for each hour of fire rating) can easily be engineered.

‘Mass timber’ should not be confused with ‘stick-built’ or ‘light-framed’ wood construction, commonly employed for single-family residential homes. Mass timber is an engineered, solid-wood system, technically falling under Type IV heavy timber construction. The current height limit for this category is 26 m (85 ft) tall, if one were to build a concrete podium with mass timber above, which likely allows for five or six stories. The 2021 International Building Code (IBC) will soon split this into three categories:

- Type IV-A for mass timber structures up to 18 stories, the catch being all structural wood must be completely concealed;

- Type IV-B for partially exposed structures up to 12 stories; and

- Type IV-C for completely exposed six-story mass timber structures.

In a mass timber skyscraper, occupants will be much more connected with natural elements through sight, touch, and even smell. This can have a profoundly positive impact on their overall well-being. Concrete office buildings often feel cold and sterile, lacking the warmth and tactile properties of wood. By contrast, mass timber buildings typically have exposed wood ceilings, beams, and columns creating a truly beautiful work and living environment. The reality is the average person spends 90 percent of the day inside and inherently prefers natural over synthetic materials. While a lot of this may sound anecdotal, West Coast mass timber buildings (e.g. Albina Yards, Portland, Oregon) are seeing rent increases as high as $7 per square foot, with happier employees, as demonstrated by increased productivity and fewer sick days. This kind of return on investment (ROI) should alleviate developers’ concerns about a one-time construction cost premium.

Canada, Austria, and Germany are the largest providers of construction lumber. The United States, too, is finally catching on to what Europeans have been using for decades. Unlike the West Coast, whose forestry industry is now facilitating a mass timber boom in states like Washington and Oregon, there are few trained installers on the East Coast. To boost domestic production, the Softwood Lumber Board (SLB), an industry-funded consortium of North American wood manufacturers, now seeks to educate architects, engineers, developers, and general contractors (GCs) about the advantages of products such as cross-laminated timber (CLT), nail-laminated timber (NLT), and dowel-laminated timber (DLT). While CLT and NLT manufacturing plants are located in Montana and Portland, DLT is only manufactured in the Canadian province of British Columbia.

These products fall under the umbrella of ‘mass timber,’ and can serve buildings whose loads would typically utilize concrete or steel structures. Yet, some may wonder, why does it make sense to build at this scale using wood, from an environmental perspective?

For starters, the construction industry alone is responsible for 50 percent of the carbon dioxide (CO2) released in the United States. As levels of carbon in the atmosphere rise, the threat of climate change increasingly presents itself as one of the greatest challenges facing this generation. Therefore, it is imperative for developers, architects, and policy makers to reconsider the use of steel and concrete. One single tree can sequester 1 tonne (1 ton) of CO2 in less than 40 years. By comparison, that same tonne of CO2 is released into the atmosphere through the production of 1 tonne of cement.

In North America, forest growth exceeds harvest by 40 percent. One of the major reasons for this is sustainable forest management, encouraged by third-party certification, by which the chain of custody can be tracked from ‘cradle-to-cradle.’ Rating systems such as the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC) help to promote responsible management of forests so they can continue to serve future generations.

Some countries do struggle with deforestation, but the main culprits are typically agriculture, mining, and land development—not the logging industry. Wood is renewable and has the ability to remove carbon from the atmosphere. Steel and concrete, on the other hand, are finite resources, and the extraction of these is not only inefficient, but also harmful to the environment. While it may initially appear to be an absurd proposal, building tall with wood is an effective way of tackling climate change on a large scale.

Timber Towers concept

The Hickok Cole design team of Anthony Maiolatesi, Rosa Zlotkovsky, and the author applied their research at the corner of Cherry and Arch Street in Center City Philadelphia, rumored to be the site of a potential third Comcast tower. They felt a technology company and industry disruptor like that would be ideal to showcase the capabilities of mass timber. For more than a century, cities have built skyscrapers using steel and concrete, and while they are iconic signifiers of innovation and prosperity, the extraction of raw materials and the energy intensive processes required for their production have been harmful to the environment. For that reason, the 60-story Timber Towers serve as a direct comparison to the existing steel Comcast skyscrapers that are each roughly the same height.

Generally speaking, mass timber projects can be built 20 percent faster and with a smaller construction crew. A typical skyscraper construction schedule is approximately three years, and so, theoretically, the builders could shave six months off that, allowing an earlier ROI. Steel and concrete pricing is typically 50 percent materials and 50 percent labor, but mass timber is closer to an 80:20 ratio, offering potential for union-heavy cities like Philadelphia to see some significant cost savings. Offsite, prefabricated construction also offers a safer working environment, and its efficiency results in fewer onsite truck deliveries and less noise.

As far as the physical limitations of mass timber construction, Hickok Cole’s design for the Skyhive Skyscraper Challenge showcased a range of building heights, demonstrating what Barber and his team at Arup believe to be the realistic limits of a purely wood building. The 30-story residential tower consists of regularly spaced CLT shear walls, utilizing the redundancy of residential modules. The structural system is therefore, like a wooden version of a concrete ‘flat plate,’ with no beams or dropped panels.

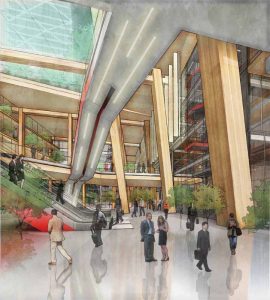

Conversely, the 45- and 60-story office towers are hybrid structures, combining mass timber (CLT slabs, glued-laminated timber [glulam] columns, and cross-bracing) with a steel core and steel connections. The columns are realistically sized based upon the recommendations of Lauren Wingo from Arup, reaching thicknesses as wide as 1.5 m (5 ft) in the main lobby, gradually tapering to a manageable 0.6 m (2 ft) on the penthouse levels. The X-bracing on the perimeter assists with lateral stability, almost as if Chicago’s Hancock Tower were built using mass timber. Wood structures are much lighter than steel or concrete, and as a result, their foundations can be up to 30 percent smaller. This lightness becomes an interesting problem for mass timber skyscrapers, and a 76-mm (3-in.) concrete topping slab is necessary on each floor to provide both ballast and acoustic isolation.

Under typical conditions, mass timber is especially suited for areas in which excavation is either difficult or prohibitively expensive. It is also better at handling lateral loads, such as wind or earthquakes. Therefore, in areas prone to inclement weather and/or seismic activity, turning to mass timber makes sense. The U.S. military has even shown interest in mass timber construction for lodging accommodations and other applications, not only because of its accelerated construction schedule capabilities, but also for how well it performs in blast testing.

Just because it can be done….does not mean it SHOULD be done! Wood in a skyscraper, no offence, are you kidding me? Even if treated for possible termite infestation, wood absorbs moisture, dimensional changes and structural integrity WILL change over the years. I personally would never live or work in a building of this stature built from wood or composites. I am all for environmental compliance and cutting edge technologies…but this is an accident waiting to happen IMHO.