Time to rethink floodproofing

by Katie Daniel | August 9, 2017 10:41 am

[1]

[1]by Brian Shaw, CFM

In addition to the hurricanes

and catastrophic floods making national headlines, a damaging flood happens frequently in the United States, caused by heavy rainfall, dam failures, land development runoff, drainage problems, inland remnants of tropical storms, or many other conditions. Flooding is the country’s leading cause of deaths related

to severe weather. Additionally, almost 40 percent of small businesses[2] never reopen their doors after a flood disaster.

Given the devastating effects, it is time to rethink how we approach the mitigation of flooding’s impact. To that end, this article examines the current situation—from regulations and floodplain management basics to the role of standards in improving buildings’ resiliency in the face of potential disaster. It examines traditional dry floodproofing challenges with respect to setup efficiency while exploring the benefits of newer ‘soft’ technologies.

The need for better floodproofing

In an increasing number of areas around the country, the risk of flood is acute. More than 72 million ha (178 million acres) have been designated as regulated floodplains by the Federal Emergency Management Agency (FEMA). These areas are steadily growing, with more people finding themselves in a floodplain as maps are redrawn to reflect changes in conditions and development, along with improvements in scanning technology, additional years of climate change, flood and topographic data, and more-advanced prediction models.

Last year, the United States had 19 separate floods[3] swamp the nation—the most in one single year since records began in 1980. According to an analysis by global reinsurance firm Munich Re, the worst was in Louisiana in August. At least 13 people were killed and roughly 60,000 buildings were destroyed. The disaster, noted as the country’s worst natural catastrophe since Superstorm Sandy in 2012, cost $10 billion.

Congressional Research Service data show the National Flood Insurance Program (NFIP) paid out between $12 and $15 billion in claims after Sandy. The U.S. Department of Housing and Urban Development (HUD) estimates that storm caused a total of $65 billion in damages and economic loss. Flood losses for the early October 2015 river and stream flooding in South Carolina are still expected to top $1 billion. Whether from coastal storm surges or catastrophic rain events, flood damage represents one of the largest potential burdens on government and commercial resources. Sandy showed floodproofing approaches must be rethought.

[4]

[4]Especially in coastal areas, flood-event frequency is projected to rise steadily over the next several decades. The U.S. National Oceanic and Atmospheric Agency (NOAA) notes sea levels rose annually about 1 to 2.5 mm (0.04 to 0.1 in.) since 1900, and the rate appears to be accelerating. Using newer satellite altimetry, sea level rise has been measured at an average of 3 mm (0.12 in.) annually since 1992. Even conservative projections of future sea level change suggest a rise of 300 to 508 mm (12 to 20 in.) over the remainder of this century, with some estimates much higher. (Visit www.usatoday.com/story/tech/sciencefair/2017/05/23/sea-level-rise-accelerating-study/102068034[5] or the September 2013 issue of National Geographic for the article, “Rising Seas,” by Tim Folger and George Steinmetz. For more, visit www.nationalgeographic.com/magazine/2013/09/rising-seas-coastal-impact-climate-change[6].) Unsurprisingly, flooding frequency in coastal areas is expected to go up.

[7]

[7]Regulated areas subject to flooding

The National Flood Insurance Program is the primary unifying approach to protecting lives and property from flood hazards. Created by the 1968 National Flood Insurance Act, it is now under FEMA’s oversight. Although NFIP was initially meant to create a large national pool of policyholders to lower flood insurance premiums, it soon became evident there needed to be some kind of standard for building in floodplains to encourage wiser use of those risky areas and minimize payouts on federal flood insurance claims.

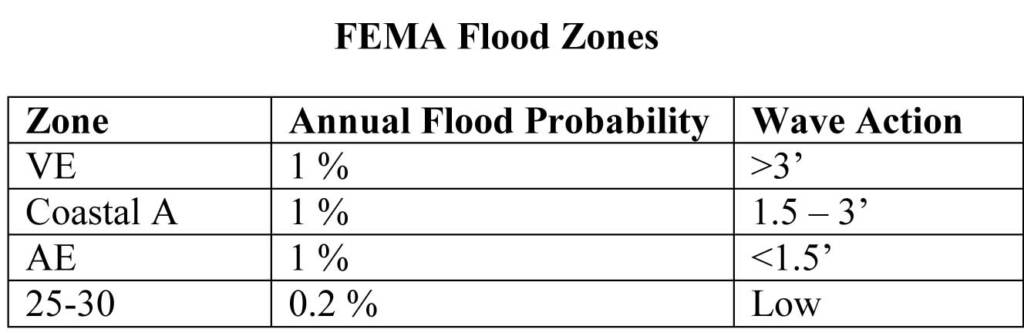

NFIP’s primary approach to reducing flood risks is through adopting minimum standards for placement and design of structures located within identified ‘one-percent annual chance flood-hazard areas.’ Its goal is to reduce those risks, as eliminating them altogether is impossible without avoiding those areas. The probability of flooding of a certain extent in a particular area is described in FEMA’s Flood Insurance Rate Maps (FIRMs).

While risk levels vary, every area on this planet’s surface is subject to some probability of flooding. Therefore, FEMA’s maps indicate minimal, moderate, and special flood hazard areas (SFHAs). It is the last of these that triggers mandatory flood insurance requirements when a structure in this risk area serves as collateral for a loan issued by a government-regulated lending institution.

[8]

[8]Since SFHAs are also the basis for regulating land use in floodplains, they are sometimes referred to as ‘base’ or ‘regulatory’ floodplains. Shown as the darkest gray areas on FIRMs, they are subject to a one-percent annual chance probability of being inundated in any given year. As this probability is present each and every year, the former nomenclature of ‘100-year floods’ has been phased out due to general misunderstanding of the actual risk involved. It is possible to experience a so-called 100-year flood in consecutive years, or even multiple events in a single year.

Other risk areas are shown on FIRMs in lighter gray (i.e. moderate risk [0.2 percent annual chance]) or white (i.e. minimal risk [less than 0.2 percent chance]). While not as likely to experience flooding, these areas are not immune, and the resulting damages can be every bit as severe as within an SFHA. Although not federally mandated, communities participating in NFIP may proactively impose the same floodplain management and mitigation requirements in these areas as within the SFHA.

Standard insurance policies do not cover floods. NFIP was created to provide flood insurance, but also to prevent the associated damage in the first place by encouraging effective management and use of floodplains. Community participation in NFIP is voluntary, but flood insurance and many types of disaster assistance are only available in communities that participate by adopting and enforcing floodplain management and construction ordinances that meet or exceed NFIP guidelines. More than 20,000 communities participate in NFIP in an effort to avoid the skyrocketing costs associated with disaster assistance, repair, and rebuilding.

NFIP insurance is available to anyone, and FEMA encourages homeowners, business owners, and renters even in low-risk areas to purchase flood insurance, since at least 25 percent of flood insurance claims every year come from low- and moderate-risk flood areas. In designated SFHAs, however, flood insurance is mandatory. Premiums are based on the specific measures taken in the building, and can vary widely depending on what floodproofing options are used.

With luck, most of the buildings built to NFIP standards will never face a catastrophic flood, but effective floodproofing measures also result in more-durable structures that require less maintenance and suffer an estimated 80 percent less damage every year. If the worst case does occur, the right floodproofing option increases a building’s sustainability in a fundamental way, often determining whether it survives.

[9]

[9]Floodplain management basics

The decision-making process of determining how to reduce unavoidable risks is termed ‘floodplain management.’ It can include both structural methods to try to hold water at bay, such as dams, levees, or infrastructure barrier systems, and nonstructural methods modifying how humans interact with their environment. Nonstructural approaches include zoning, subdivision, health, and building codes to safeguard lives and property from direct and indirect harm associated with inundation events.

Communities participating in NFIP must adopt local floodplain management ordinances meeting or exceeding certain minimum standards pertaining to flood risk reduction strategies. These strategies may include explicit requirements for flood-venting devices, gradient changes, and location of in-home utilities on limited floors. They pertain to not only mudslide-prone areas and flood-related erosion-prone areas, but also properties in flood zones, such as SFHAs.

Repercussions for failing to enforce ordinances or having inadequate ones can include the inability of property owners to purchase or renew federal flood insurance, ineligibility for mitigation or disaster assistance, and even the penalty of an entire community suffering the cost of increased insurance premiums. To ensure this does not happen, state floodplain managers and local code officials are charged with:

- overseeing floodplain use and development to protect new construction in or near those floodplains;

- accounting for cumulative effects of floodplain development on existing construction; and

- ensuring correct, consistent enforcement of local, state, and federal regulations throughout affected areas. (Regulations come down from the state, but local officials have final say and can enforce more stringent local rules.)

Errors or omissions can have terrible consequences, including endangering lives and hampering emergency response efforts. Those designing new or retrofitted structures must take care to adhere to local requirements that may be more stringent than federal minimum criteria, imposing additional site constraints and conditions before permit approvals. This is particularly true in communities participating in the voluntary Community Rating System (CRS), in which points earned for proactive floodplain management practices can reduce flood insurance premium rates throughout the jurisdiction. Applying regulatory mandates, FEMA provides a series of Technical Bulletins (such as TB-1, issued in August 2008), and the NFIP Insurance Manual, to provide instruction and practical, real-world approaches to floodplain management.

Mitigating against flood risks

Special Flood Hazard Areas are divided into zones beginning with the letters A or V. There are also numerous subdivisions (e.g. AO, AE, VE) based on varying types of risk for the exact topography and other characteristics of the area. V-zones

are in coastal floodplains where high-velocity wave action could occur during the base flood so building designs must account for hydrodynamic forces. A-zones can be on coastal floodplains, but they can also be in inland areas. (High-velocity waves are not expected in A-zones, so most damage results from hydrostatic forces, as discussed in more detail later in this article.)

A new flood zone is a ‘Coastal A-zone,’ which typically falls in between a V- and an A-zone. Careful attention must be given to the local floodplain ordinance for the community in which the project is located. In many cases, the community will enforce V-zone construction restrictions in Coastal A-zones, and this can limit one’s designs.

Codes and regulations specify floodproofing measures in relation to the base flood elevation (BFE)—the water surface elevation associated with the aforementioned ‘100-year flood’ that has a one-percent annual chance of occurring. The basic standard for floodplain development, the BFE is used to determine the required elevation of the lowest floor of any new or substantially improved structure. The BFE, plus any freeboard requirements, is also utilized to set the design flood elevation (DFE) of dry floodproofing solutions. The various means of attempting to reduce losses from flooding disasters are referred to as ‘mitigation measures;’ the appropriate approaches vary with the identified flood zone in which a building is located.

Structures in V-type zones must be elevated above the ground to minimize obstruction to the passage of waves beneath them. For all new construction and substantial improvements in V-type zones, the bottom of the lowest horizontal structural member of the lowest floor (excluding the pilings or columns) must be elevated to or above the base flood level. There must also be anchoring to resist flotation, collapse, and lateral movement due to the effects of wind and water loads acting simultaneously on all building components.

Structures in V-type zones are limited to wet floodproofing below the base flood elevation. It is important to note any enclosed area below the BFE is required to be built out of breakaway walls and have flood openings complying with American Society of Civil Engineers (ASCE) 24-14, Flood-resistant Design and Construction. For NFIP insurance purposes, the enclosed area should be limited to 28 m2 (300 sf)—anything larger results in higher flood insurance premiums.

For most A-type zones, elevation of a new or substantially improved structure’s lowest floor (including the basement) must be to or above BFE, or at least as high as the depth number specified on the FIRM if only a depth and no elevation is provided. Coastal A-type zones are the exception; by reference to ASCE 24-14 and the International Building Code (IBC), these areas are subject to the same elevation requirements as V-type zones.

Structures in noncoastal A-type zones are also eligible for other protection methods in addition to elevation. These floodproofing options include both strategies that are ‘dry’ (i.e. attempts to seal out water) and ‘wet’ (i.e. allowing water to enter the structure to equalize hydrostatic pressure). Dry floodproofing is unacceptable in V-type zones, where the dynamics of surging water overcome any human attempt to withstand such forces. In these locations, the only approach to protection is elevation (as it enables such forces to pass freely beneath the building), coupled with specifying water-resistant materials to slow corrosion and decay. It is important to note residential structures in SFHAs are required to wet-floodproof applicable enclosures below the BFE while nonresidential structures can be designed with dry or wet methods.

[10]

[10]Building standards

Building standards established in Chapter 16 of IBC and in ASCE 24-14 reflect and support the minimum floodproofing and construction criteria established by FEMA’s regulations and Technical Bulletins. In many cases, they go above and beyond those requirements to establish higher standards that have proven to be needed.

Addressing use of specific materials and construction methods, IBC provides a model code and minimum standards for building materials, building structure, safeguarding of public health, safety, and general welfare of occupants. Of most relevance to the current topics are Chapter 16, “Structural Design” (particularly structural loads, including from flooding) and Appendix G, “Flood-resistant Construction.” Under the former, Section 1612, “Flood Loads:”

- requires communities to adopt maps of flood hazard areas (which, incidentally, provide public notice of where regulations apply and support municipal floodplain management decisions);

- recommends implementation of design flood elevations to raise lowest floors above base flood elevations;

- establishes ASCE 24 as one of the primary standard documents for design and construction within the SFHA; and

- mandates registered design professionals provide flood hazard documentation (e.g. elevation of lowest floor and certifications regarding floodproofing and construction design).

Floodproofing

Generally, floodproofing is the implementation of structural and nonstructural methods to reduce flood damage to a structure, its contents, and related utilities and equipment. The object is to minimize both hydrodynamic and hydrostatic pressures of floodwaters against the walls of a structure—‘hydrodynamic’ referring to the force of moving water and ‘hydrostatic’ to the weight and pressure of still water.

FEMA TB 3, Nonresidential Floodproofing–Requirements and Certification for Buildings Located in Special Flood Hazard Areas, identifies some of the minimum engineering considerations of dry floodproofing. These include a requirement to make the building watertight to the floodproof design elevation, being at least 0.3 m (1 ft) beyond BFE. (The additional 0.3 m of freeboard is critical for NFIP flood insurance rating purposes.)

A dry-floodproofed building’s structural components must be able to resist hydrostatic and hydrodynamic flood forces, buoyancy, and debris impact forces. Another great resource for understanding the requirements as they pertain to existing structures is FEMA P-936, Floodproofing Nonresidential Buildings.

Dry floodproofing can include passive measures such as waterproof sealants and coatings on walls and floors, along with automatic backflow prevention valves and sump pumps. However, it may also involve active measures—such as flood barriers, gates, shields, or doors—that must be manually activated when high water is expected. The designer has to account for important planning considerations by knowing answers to the following questions:

- How much warning time is likely to be available?

- How will people enter and exit the building?

- What is the flood frequency in the area?

- What are the expected floodwater velocities, flood depths, and debris impact?

Features of dry floodproofing systems include:

- sealants, coatings, and membranes to reduce seepage of floodwater through walls and their penetrations;

- flood barriers, shields, and panels for openings (e.g. doors and windows) attached to the structure’s façade;

- reinforcement of walls to withstand floodwater and floating debris;

- anchoring of the building to resist flotation, collapse, and lateral movement;

- pumps to control interior water levels due to seepage;

- check valves to prevent the entrance of floodwater or sewage flows through utilities;

- location of electrical, mechanical, utility, and other valuable damageable equipment and contents above the expected flood level or DFE; and

- a minimum of one ingress/egress door or other approved opening above the established DFE.

Dry floodproofing requires emergency operation planning, some of which is related to site selection. As some approaches include placing barriers over openings, advance disaster planning is crucial to ensure all individuals are out before sealing and locking those barriers. Engineering considerations for dry floodproofing include a regular inspection and maintenance plan to ensure all components operate properly under all conditions, including power failure. Mechanical equipment, generators, flood barriers or logs, and flood shields (including gaskets) should be inspected and repaired annually (at minimum). Further, foundation walls, levees, and berms must be inspected and repaired to ensure there are no cracks.

Section 1.1 of ASCE 24 addresses dry floodproofing as a method to render a structure “substantially impermeable (This is echoed in U.S. Army Corps of Engineers [USACE] EP 1165-2-314, Floodproofing Regulations.),” resulting in:

a space free of through cracks, openings, or other channels that permit unobstructed passage of water and seepage during flooding, and which result in a maximum accumulation of [100 mm] 4 inches of water depth in such space during a period of 24 hours.

This requires substantial attention to choice of materials, construction techniques, and testing to meet the stated standard. A floodproofing certificate for nonresidential structures (Office of Management and Budget [OMB] No. 1660-0008) must be signed and sealed by a properly licensed design professional certifying to having developed or reviewed the floodproofing design plans, specifications, as-built drawings for construction, and physical inspection to comply with accepted standards of practice for dry floodproofing (i.e. ASCE 24-05, ASCE 24-14, or their equivalent).

For flood insurance premiums to reflect the additional protection and lower risk, dry floodproofing must extend 0.3 m (1 ft) above BFE. A typical scenario could see an annual NFIP insurance premium go from $38,615 to $4823 with compliant dry floodproofing measures.

The challenge of traditional flood protection solutions

Industry professionals have identified most floodproofing designs experience breaches at opening points. For buildings located in flood-prone areas, only a few flood protection options have been available until recently. Historically, the most common system has relied on stop logs—a system of vertical, slotted posts holding stacks of horizontal rectangular ‘logs’ that can be erected around the building or critical doorways and openings to form a continuous barrier. The most significant issue with stop logs—and similar aluminum-sheet barricade systems—involves the materials’ storage.

These components must be kept onsite in what could otherwise be valuable, revenue-generating space, or they have to be stored offsite, often at some distance from the building they are intended to protect. It can take as long as a week to retrieve the truckloads of materials required to erect a barrier around the perimeter of a typical commercial or government building. Having the necessary labor and equipment at the time of need is also a big concern.

For weather-related events, this can mean having to make a decision whether or not to deploy well before forecast models have reached a consensus about storm paths and severity. Deploying unnecessarily is expensive, but hesitating to deploy to avoid that expense can be catastrophic. Further, because

of the unpredictable nature of some natural disasters, like earthquakes or dam breaks, and terror-related acts that can cause flooding, it can be virtually impossible to retrieve and erect a stop-log or barricade system in time. (The Department of Homeland Security (DHS) Science and Technology Directorate [S&T] is researching technologies that can prevent or limit flooding in transportation tunnels. For more, visit www.dhs.gov/sites/default/files/publications/Resilient%20Tunnel%20Project-508_0.pdf[11].)

Having experienced this during Superstorm Sandy, New York City now requires an annual deployment of the flood barrier systems to ensure facility maintenance staff are familiar with the systems and their use. This flood drill has always been part of the ASCE 24 standards, which calls for periodic testing of the barrier systems, but now communities are clearly stating the requirement in their floodplain ordinances. This clarification is now driving up the cost of ownership of the systems that need to be retrieved, as they also require extensive labor and equipment to deploy. These are all factors that play into a dry floodproofing system not being deployed in time.

The need for quick-deployment solutions

Recognizing the weaknesses in existing flood mitigation technology, new dry floodproofing methods have emerged in the form of flexible barriers offering versatility and resiliency. Using soft goods, as opposed to hard metals, allows for a flood mitigation system providing full flood protection, employing equipment that could be stored in place and deployed rapidly by building maintenance or security staff.

System design objectives for these new technologies were established after a careful analysis of available systems and field assessments following Superstorm Sandy. They include:

- point-of-use storage (allowing the facility to stay open until the last possible moment, and reopen faster for higher business continuity);

- quick-deployment architecture to ensure minimal setup and quick retraction;

- low operational impact (i.e. simple to install, requiring only one or two people to deploy);

- low stowed volume to fit in tight spaces located at the point of use;

- low maintenance based on minimal mechanical complexity;

- high reliability via simple designs and robust construction;

- lightweight materials to facilitate both safe and rapid manual operation;

- conformal materials adaptable to any opening; and

- scalability (i.e. able to be easily sized and configured to structural profile and expected loading, capable of protecting more than 4.3 m [14 ft] of flood height).

Flood mitigation products have various application points, including the following:

- building entrances;

- stairwells (see “Customizing a Stairwell Solution”);

- doors;

- windows and curtain walls;

- storefronts;

- below-grade window wells;

- ventilation shafts;

- intake/exhaust openings;

- parking garage and loading dock portals;

- vehicular entrances;

- emergency exits; and

- rail and vehicular tunnel portals.

The new solutions to address these points include flexible walls, gates, covers, and plugs—together, these represent an advanced structural technology that can meet resiliency needs.

For commercial and government buildings, the most commonly used new technology are flexible wall barrier systems. These employ flexible Kevlar composite or polyester webbing woven into an extremely tough mesh fabric with a PVC-coated polyester to serve as the water barrier retention layer. The resulting soft goods combination can hold up to micrometeorite impact testing. (For more on this, visit www.nasa.gov/centers/wstf/laboratories/hypervelocity/mmod.html[12] and en.wikipedia.org/wiki/Thermal_Micrometeoroid_Garment[13].)

The flexible wall barrier is supported by rugged structural members (steel or aluminum, depending on the application needs), but with its soft goods base, the system can be deployed easily by one or two persons, often in minutes. Even a full-perimeter, 2.4-m (8-ft) flexible wall barrier can be erected around a typical commercial building in a matter of a few hours, because all materials are stored at the point of use, and only have to be extended and locked in place.

Once conditions are safe, the flexible wall systems can be stowed as efficiently as they are deployed. After a flood, normal business operation can resume in hours or a couple of days depending on cleanup requirements— rather than the weeks required to clean, dismantle, and cart the components of traditional stop-log or aluminum-plate systems to storage facilities. If no flooding occurs, the flexible wall stows quickly; normal operations can usually be resumed in about the same time required to deploy.

The barrier system is typically installed in a horizontal trench just below grade, or in a vertical container installed at the side of a doorway or portal opening. As the wall material is flexible, it can be packed into a small container. For instance, the flexible barrier portion of a 2.4-m vertical wall can fit in a space of 200 x 200 mm (8 x 8 in.). Total trench cross-section can then be the 200 x 200-mm space for the wall, plus enough additional space for the support posts, lying flat. With such small size, the flexible wall barrier system requires minimal infrastructure modification for installation. The wall can also be scaled in height and length to fit any application and is self-contained; therefore, no special tools or training is required for operation.

A variation of this design is also available in a rolled-up version, which makes it ideal for certain historical applications where modifications to the building are limited due to preservation requirements. This is also suitable for existing buildings seeking to minimize modifications.

Conclusion

Recent flooding events have shown the importance of deployment time for infrastructure flood protection systems. The devastating damage and economic loss totals, as well as the loss of life, from Superstorm Sandy demonstrated current floodproofing techniques are useless when they are not deployed. The traditional systems of employing solid, metal barriers or logs require massive storage space and extensive setup and deployment time. The new dry floodproofing concept of flexible, soft goods stored at the point of use addresses these issues and may be the solution building owners, architects, and builders never knew they needed.

| CUSTOMIZING A STAIRWELL SOLUTION |

[14] [14]This flexible flood gate is a high-strength, point-of-use stored, and rapidly deployable protector of stairwells. Currently being used across the New York City subway system, it is scalable to water levels up to 9 m (30 ft) and can be deployed during high winds. A high-strength closure for New York City’s subway system stairwells is constructed from textile-based materials within a structural frame; it was born out of the need for rapidly deployed, flood protection stored onsite. The key requirements by the client included the ability to be stored at the point of use to allow the system to stay open until the last minute, provide a return to normal operations faster, and ensure components are not misplaced between events. The system also needed to be able to withstand up to 4.3 m (14 ft) of water head pressure, given updated Federal Emergency Management Agency (FEMA) flood maps. For this project, no inward loads could be placed on the concrete structure of the stairwell—in other words, the floodproofing system needed to react to all inward loads. It also could not encroach on the stairwell, along the sides, at the top step, or at the header. The assembly, which needed to be able to withstand vandalism, was required to be deployed by transit station personnel in under 30 minutes. It also needed to be deployed mechanically rather than rely on power that may be unavailable during a major storm. Achieving these goals involved using soft goods technology developed for National Aeronautics and Space Administration (NASA) programs such as the spacesuits that walked on the moon, the Pathfinder Landing impact bags that supported successful landings on Mars, and inflatable space habitats. The benefits of textile tension fabric membranes include:

The stairwell waterproofing system functions similarly to a window shade or rollup storefront security door. The primary components include its cover, storage container, gate guides, and top-step deployment mechanism. When the notice to deploy is given, the tamperproof cover plates on the gate guides are released and the top step is opened. The cover is deployed by retrieving a T-bar from the storage container and turning a drive spool that allows integral cables to pull the cover through the gate guides toward the top-step mechanism. Once fully deployed, the cover is bolted in place via a seal bar integral to the cover. The seal is accomplished at the gate guides and top-step seal bar. The fabric cover chosen for this application includes Hypalon-coated Kevlar, a tightly woven structural netting made with 3855-kg (8500-lb) Kevlar webbings, and a Kevlar rope sewn into the assembly to function as the ‘dead man’ to prevent pullout and assist in sealing along the gate guides. To date, 24 systems have been installed at New York City subway entrances, and are at the ready for the next major storm event. |

Brian Shaw, CFM, is the director of sales and marketing for Smart Vent Products Inc. He has studied the science of flood mitigation for more than a decade, with a concentration in proper floodproofing techniques to ensure resilient structures. Shaw analyzes the role of building compliance in securing lower flood insurance rates and available mitigation solutions. As a Certified Floodplain Manager, he has traveled the country to educate professionals on the U.S. Federal Emergency Management Agency’s (FEMA’s) wet and dry floodproofing regulations and floodplain related issues with a primary focus on working with architects, engineers, and city officials. Shaw can be reached at bshaw@smartvent.com[15].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/08/Flex-Wall-2.jpg

- small businesses: http://www.fema.gov/protecting-your-business

- 19 separate floods: http://www.usatoday.com/story/weather/2017/01/04/floods-natural-disasters-2016/96120150

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/08/FEMA-Flood-Zones.jpg

- www.usatoday.com/story/tech/sciencefair/2017/05/23/sea-level-rise-accelerating-study/102068034: http://www.usatoday.com/story/tech/sciencefair/2017/05/23/sea-level-rise-accelerating-study/102068034

- www.nationalgeographic.com/magazine/2013/09/rising-seas-coastal-impact-climate-change: http://www.nationalgeographic.com/magazine/2013/09/rising-seas-coastal-impact-climate-change

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/08/edit1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/08/edit2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/08/edit3.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/08/egressIMG_8620.jpg

- www.dhs.gov/sites/default/files/publications/Resilient%20Tunnel%20Project-508_0.pdf: http://www.dhs.gov/sites/default/files/publications/Resilient%20Tunnel%20Project-508_0.pdf

- www.nasa.gov/centers/wstf/laboratories/hypervelocity/mmod.html: http://www.nasa.gov/centers/wstf/laboratories/hypervelocity/mmod.html

- en.wikipedia.org/wiki/Thermal_Micrometeoroid_Garment: http://en.wikipedia.org/wiki/Thermal_Micrometeoroid_Garment

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/08/EDIT4.jpg

- bshaw@smartvent.com: mailto:bshaw@smartvent.com

Source URL: https://www.constructionspecifier.com/time-to-rethink-floodproofing/