by Arthur L. Sanders, AIA, and Benjamin J. Robinson, AIA

Exterior insulation and finish systems (EIFS) are proprietary wall cladding assemblies that combine rigid insulation board with a water-resistant exterior coating. Popular chiefly for their low cost and high insulating values, they are used on a range of construction types, from hotels to offices to homes.

Unlike traditional stucco, which is composed of inorganic cement-bonded sand and water, EIFS employs organic polymeric finishes reinforced with glass mesh. As an energy-efficient, economical wall covering, EIFS can be effective for both new construction and recladding applications. However, successful use of EIFS is highly dependent on proper design and sound construction practices. Without correct design and detailing, EIFS wall systems have been known to fail dramatically.

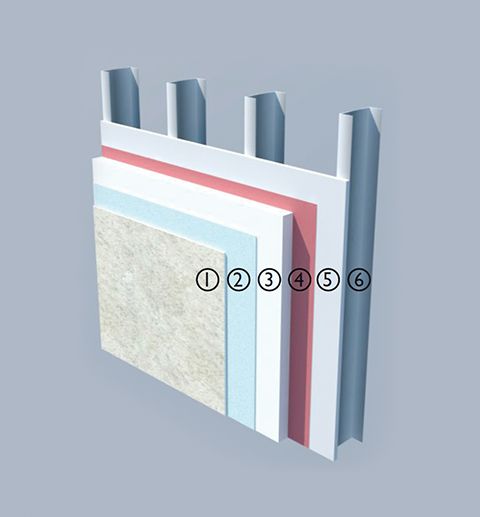

Elements of an EIFS wall assembly

EIFS are multi-layer systems that typically consist of six basic components:

- substrate—usually exterior gypsum board, oriented strandboard (OSB), or plywood;

- membrane or rainscreen (some systems);

- exterior insulation (adhesively or mechanically fastened);

- base coat—consisting of proprietary acrylic copolymer dispersions and powder additives;

- reinforcing glass fiber mesh; and

- finish coat, or ‘lamina,’—comprising copolymer dispersions, colorants, and stabilizers.

Primer may be applied to the substrate before waterproof membrane application, or it may be used on the insulation board before applying the base coat. Although primers are usually optional for EIFS, they may be used to minimize water absorption, reduce efflorescence, improve trowelability and coverage, and promote color consistency.

There are two major types of EIFS. The first, Class PB, represents the majority of EIFS used in North America.

Class PB (polymer-based)

Known as ‘soft-coat’ EIFS, Class PB systems use adhesively fastened expanded polystyrene (EPS) insulation with glass fiber reinforcing mesh embedded in a nominal 1.5 to 3 mm (1⁄16 to 1⁄8 in.) base coat.

Class PM (polymer-modified)

‘Hard-coat’ EIFS were developed for improved impact resistance. Reinforcing mesh is mechanically attached to extruded polystyrene (XPS) insulation, over which a thick, cementitious base coat of 6 to 9.5 mm (1⁄4 to 3⁄8 in.) is applied.

Direct-applied exterior finish system (DEFS)

DEFS is the exterior finish part of EIFS without the insulation. Base and finish coats are applied directly to the substrate. Mainly used for soffits, stairwells, and high-impact-prone areas that do not require insulation, DEFS may be applied to cement board, concrete masonary units (CMUs), exterior-grade plywood, polyisocyanurate (polyiso) board, or other proprietary products.

EIFS with drainage

Also known as ‘rainscreen EIFS,’ EIFS with drainage are installed over a waterproofing barrier with drainage channels for removal of incidental moisture behind the insulation board. Often, these channels are formed by applying adhesive in longitudinal strips or by using insulation board with vertical grooves. The effect is similar to that of a cavity wall, where the space behind the exterior facing drains or dries any moisture that manages to penetrate the cladding. EIFS with drainage were introduced in 1996, following a 1995 class-action lawsuit involving widespread failure of traditional barrier EIFS.

Although EIFS with drainage address the water-intrusion problems of face-sealed EIFS, they are not a foolproof solution. Should the vapor barrier or moisture retarder fail, water can still enter the assembly. Therefore, air and water barriers must be designed to last the life of the system.

Common EIFS failures and preventions

Originally, EIFS were designed as a ‘perfect barrier’ system—one which provides waterproofing protection at the exterior face of the cladding. The idea of barrier cladding assemblies is to create a face-sealed façade that repels moisture to keep the building dry.

Unfortunately, barrier systems are rarely perfect. All it takes to compromise watertightness is a small breach in the exterior finish, such as cracks from expansion, sealant failure at joints, or impact damage. Once water finds its way into a barrier system, it usually cannot find its way back out. Water trapped in the wall can lead to leaks, wet substrate, mold, deterioration of building components, and eventually, collapse of the weakened cladding.

Any number of deficiencies can lead to EIFS failure. The major culprits are poor workmanship, damp climate, impact damage, building movement, and incompatible or unsound substrate.

I didn’t know there were so many different types of insulation. I like having different choices so this is great for me! Insulation is a crucial part of building an efficient structure so this will be really helpful.

Great explanation of the different types of insulation available. I had no idea there were so many different kinds so this is really helpful.

I had no idea there was a difference between stucco and exterior insulation and finish systems. I assumed that stucco was the same thing as the insulation board and exterior coating that you are discussing in your article! I’ll be sure to look at my options more carefully when I need some exterior waterproofing done!

The article has a beneficiary content, which has helped me a lot in understanding. It is a very informative blog which everyone should read to know.