Fire-resistive glass

The Salesforce Transit Center glass walkway also required a two-hour firing rating. In the event of a fire, the intumescent layers in the multichambered, fire-resistive tempered safety glass will react, blocking smoke and flames, while also reducing the transmission of radiant heat.

Fire-resistance testing

Testing played a major role in the system solution. The process began with a series of preliminary fire tests at the manufacturer’s fire-testing lab to prove various glass combinations and ultimately led to the construction of a full-scale mockup for final testing and certification at Underwriters Laboratory (UL) in Northbrook, Illinois, to UL 263, Standard for Fire Tests of Building Construction and Materials, and ASTM E119, Standard Test Methods for Fire Tests of Building Construction and Materials. The final certifications demonstrated the complete floor system could stand up to two hours of fire exposure while maintaining its loadbearing ability.

Accelerated weather testing

The assembly also underwent weather testing to meet ASTM E2188, Standard Test Method for Insulating Glass Unit Performance , and E2190, Standard Specification for Insulating Glass Unit Performance and Evaluation. A 0.6 x 0.6 m (2 x 2 ft) test sample underwent 252 rounds of thermal cycling between –29 C (–20 F) and 60 C (140 F) simultaneous with 136 kg (300 lb) of cyclic rolling force. No issues were discovered following 90,000 test cycles.

Solar radiation testing

Temperature and 1000 W/m2 radiation simulation of site conditions, with readings of the glass’ various interlayer, edge, and limit temperatures was performed in a validated test apparatus at a research and development center in Germany. The test simulated five hours of direct sunlight without wind or shading, as an extreme measure, and confirmed the first two layers reflected rather than absorbed radiation. This supported product durability and reduction of solar heat gain for thermal comfort inside the building.

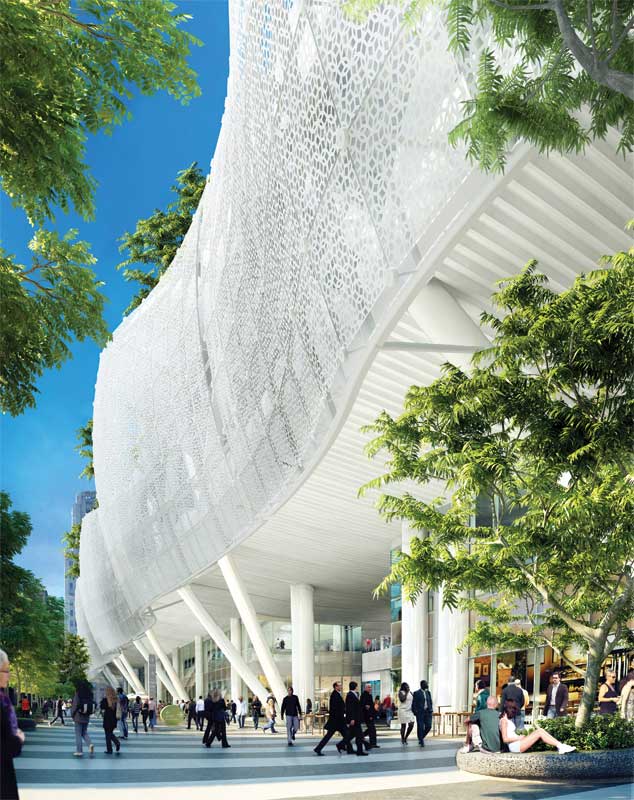

Photo courtesy Pelli Clarke Pelli Architects

Slip resistance

The units performed successfully in static coefficient of friction (SCOF) tests per three different ASTM standards (C1028-07, Standard Test Method for Determining the Static Coefficient of Friction of Ceramic Tile and Other Like Surfaces by the Horizontal Dynamometer Pull-Meter Method; E303-93, Standard Test Method for Measuring Surface Frictional Properties Using the British Pendulum Tester; and F1679-04, Standard Test Method for Using a Variable Incidence Tribometer [VIT]) to ensure safety, with wet and dry surface testing conditions.

Air and water resistance

To ensure each panel was watertight, airtight, and capable of withstanding temperature changes, field tests were conducted onsite, after installation. Gutters were flooded before glazing panels were installed; water was sprayed along each section before exterior sealant was applied; and the completed assembly was flooded for 24 hours in accordance with ASTM D5957, Standard Guide for Flood Testing Horizontal Waterproofing Installations.

The result of intense engineering alongside accompanying product and assembly testing is a robust, safe, beautiful skywalk that enhances the transit center from the outside in. With a dramatic focal point on the roof and abundant light throughout the interior, the Salesforce Transit Center is at once a destination as much as it is a hub to pass through.

Stephanie Miller is the marketing and communications manager for Vetrotech Saint-Gobain North America. She can be reached via e-mail at stephanie.miller@saint-gobain.com.

a robust, safe, beautiful skywalk that enhances the transit center from the outside in. With a dramatic focal point on the roof and abundant light throughout the interior, the Salesforce Transit Center is at once a destination as much as it is a hub

to pass through.