Pesky details

As anyone who works in the construction industry is all too aware, there is great truth to the saying, “the devil is in the details.” Even the best products can be rendered wholly ineffective by overlooked details in the specifications or installation process.

Here are some helpful tips for specifiers to ensure the best performance from gaskets and acoustical assemblies. Keep in mind gasketing may have a dual role of sound control and smoke barrier.

Coordination of gasketing and other hardware

It is important to ensure the gasketing specified does not interfere with other hardware on the door. This includes, but is not limited to, pivots, cylindrical locks, electronic hardware, surface-mounted closers, and concealed vertical rods.

Mounting hardware

Mounting hardware locations must be adjusted to accommodate any brackets used on perimeter gasketing. If the surface mounted hardware interferes with the gasketing, mounting brackets should always be used.

To prevent injuries, finger guards and finger protection hardware should be installed on both the hinge and lock side of a door. The extra seal protecting the hinges also prevent tampering and enhance security.

Fire exit or panic hardware must be properly undersized to allow for the mounting bracket over the seal. This instruction is usually given to the contractor or installer as this type of hardware can typically be modified in the field.

Properly under sizing fire or panic exit hardware is important when using brackets to cover acoustical or fire-rated gasketing products. This means, the fire exit hardware or panic exit hardware must be either field trimmed, or ordered shorter than standard, to mitigate any interference between products.

Installation

Although proper specification is crucial, the effectiveness of any acoustical assembly depends on proper installation. To ensure the integrity of the gasketing, and thus the entire acoustical assembly, is not compromised in the field, installers should keep the following tips in mind.

Continuous seal

The practice of “notching out” gasketing to create space for hardware is dangerously common as many specifiers and installers either ignore or are unaware of the need for a continuous seal. Breaking this seal creates two potential risks to occupants. The first is a security issue, as the break in the gasketing creates an access point to the secure side of the opening. The second is an even more serious threat to life safety as the door assembly was not tested with the modification. This is of particular concern with fire doors where any breaks in the seal are likely to result in the leakage of smoke into a room.

Cased-open frame

To ensure occupants’ security, particularly in hotel settings, it is imperative to avoid frames without stops, also known as cased open frames. Cased-open frames are not common in commercial settings. However, they do provide flexibility to the specification writer because it allows the ability to accept a larger range of door hardware products. Additionally, cased-open frames are specifically used in conjunction with heavy duty gasketing for openings such as boiler rooms, sound rooms, and studies. These heavy duty acoustical gasketing products must be used with a cased-open frame to ensure specified locks will not require extended spindles or special accommodations. Further, cased-open frames are used in handicap openings requiring a specific clear width of egress.

Due to the design of these frames, the gasketing can be easily removed with a screwdriver, leaving the door unsecured. In a situation where a cased-open frame is already installed, the heavy duty rated gasketing acting as the stop should be mounted with security fasteners to inhibit tampering.

Magnetic locks

Design professionals should be aware magnetic locks can cause interference with the continuous seal. They should only be used with the proper mounting bracket recommended by the manufacturer. Further, any hardware mounted onto or overlapping gasketing must be looked at carefully to ensure the seal has not been compromised, particularly in highly secure openings.

Security brackets

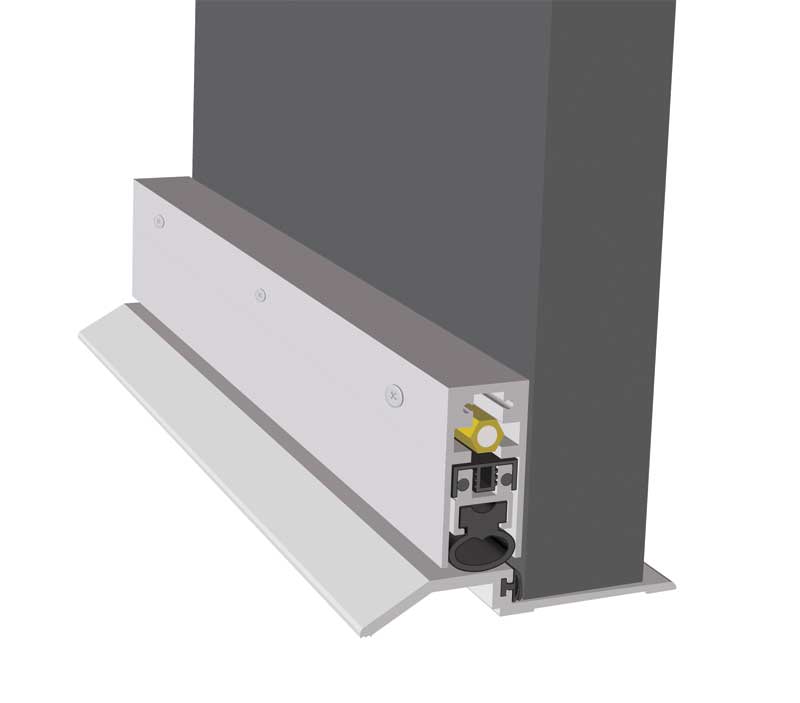

The integrity of the seal is immediately lost once the seal has been cut to allow for a strike or a surface-mounted closer. For this reason, it is mandatory to use security brackets over any type of perimeter seal. Figure 2 (page 80) shows the proper way to install a security bracket to allow for a surface-mounted roller strike to be installed. The security bracket allows for a continuous seal around the opening, which is consistent with the test successfully performed on the opening prior to rating. Additionally, the security bracket helps prevent hardware tampering.

Antibacterial gaskets

In high-traffic areas like hotels, schools, and hospitals, the fight against the spread of microbial contaminants starts at the doors. Installation of antibacterial rubber gaskets can help minimize microbial transmission and maintain a sanitary environment.

Conclusion

Since the science of sound control is so complex, these are only a few of the common challenges specifiers and installers might face when dealing with the problem of noise in any type of facility. Specifiers looking for additional details on gasketing and acoustical assembly requirements should consult the National Fire Protection Association (NFPA) 105, Standard for Smoke Door Assemblies and Other Opening Protectives, and NFPA 101, Life Safety Code.

While many acoustical problems can be avoided by following the tips contained in this article, door and hardware professionals advising designers and owners are strongly encouraged to consult with acoustical engineers during the planning process. Hiring expert installers will also ensure the result of all their planning and specifications is the beautiful sound of silence.

Jacob Wexler, FDAI, is the president of Legacy Manufacturing. He can be reached at jacob.wexler@legacyllc.com.