Basic exterior wall design concepts

The fact adhered masonry veneer systems differ from typical masonry cavity walls does not mean ignoring basic and proven building science concepts and required building codes of moisture management, energy control, and durability. When using adhered masonry veneers, designers still need to understand:

- how the exterior wall drains and dries when it gets wet;

- ways the exterior wall system controls air, vapor, and associated condensation and energy implications;

- methods to incorporate continuous insulation;

- how the thin cladding products and wall accessories react close to grade or when exposed to de-icing solutions;

- strategies for accommodating material and differential building movement; and

- approaches to selecting durable wall components to create resilient exterior assemblies.

Type of adhered masonry veneers

As adhered masonry veneer systems come with many different types and configurations, along with veneer and internal wall component choices, they should be selected carefully to perform in their respective climate zone. Exterior thin veneer systems can be clad with natural or manufactured brick, natural stone, manufactured stone, ceramic or porcelain tile, fiber-cement products, or other materials. Veneer units can be adhered with traditional mortar, modified mortar, or synthetic materials. Cladding units can be installed as individual units or panelized systems. In more severe climates, the thin veneers industry has learned that polymer-modified mortars or proprietary premium mortars perform better than traditional mortar.

Further, adhered masonry veneer wall systems can be designed either as a barrier or drainage wall, each with its own considerations.

Barrier walls

There are two types of barrier walls: ‘mass walls’ or ‘skin walls.’ Design strategies employing the former with historic masonry walls generally worked well with sufficient thickness and multiple layers of masonry to absorb and release moisture to prevent it from getting to the interior surfaces. However, because of the thin profiles of adhered masonry veneers, these systems have diminutive moisture storage capacity. Therefore, mass wall design strategies with adhered masonry veneer systems are risky and only appropriate in dry climates or if a robust and tested air and moisture barrier is applied to the support wall, before the adhered cladding, and metal lath fastener penetrations are eliminated or sealed.

A ‘skin wall’ is a type of mass wall assembly that depends on a seal at the exterior surface of the cladding to keep moisture out—rather than having any drainage components within the assembly. Skin wall strategies are only as good as the seal; they are generally not recommended for adhered masonry veneer because the surface seal can be easily compromised by building movement, material movement, penetrations, or ultraviolet (UV) degradation that leaves the system vulnerable to moisture damage.

Many recently investigated premature adhered veneer failures have occurred with assemblies utilizing mass wall strategies—especially when the support wall comprises moisture-sensitive materials such as wood framing and wood-based sheathing. In a few recent Upper Midwest cases involving adhered masonry veneer over wood walls, there has been:

- cracked or debonded units;

- deteriorated or swollen wood sheathing and framing members;

- deteriorated assembly components (e.g. corroded metal lath and fasteners);

- window damage; and

- mold.

These issues have been seen in walls as ‘young’ as one to six years (Figure 2). Most of these failures can be traced back to faulty design and material choices, while others can be attributed to poor workmanship.

Drainage walls

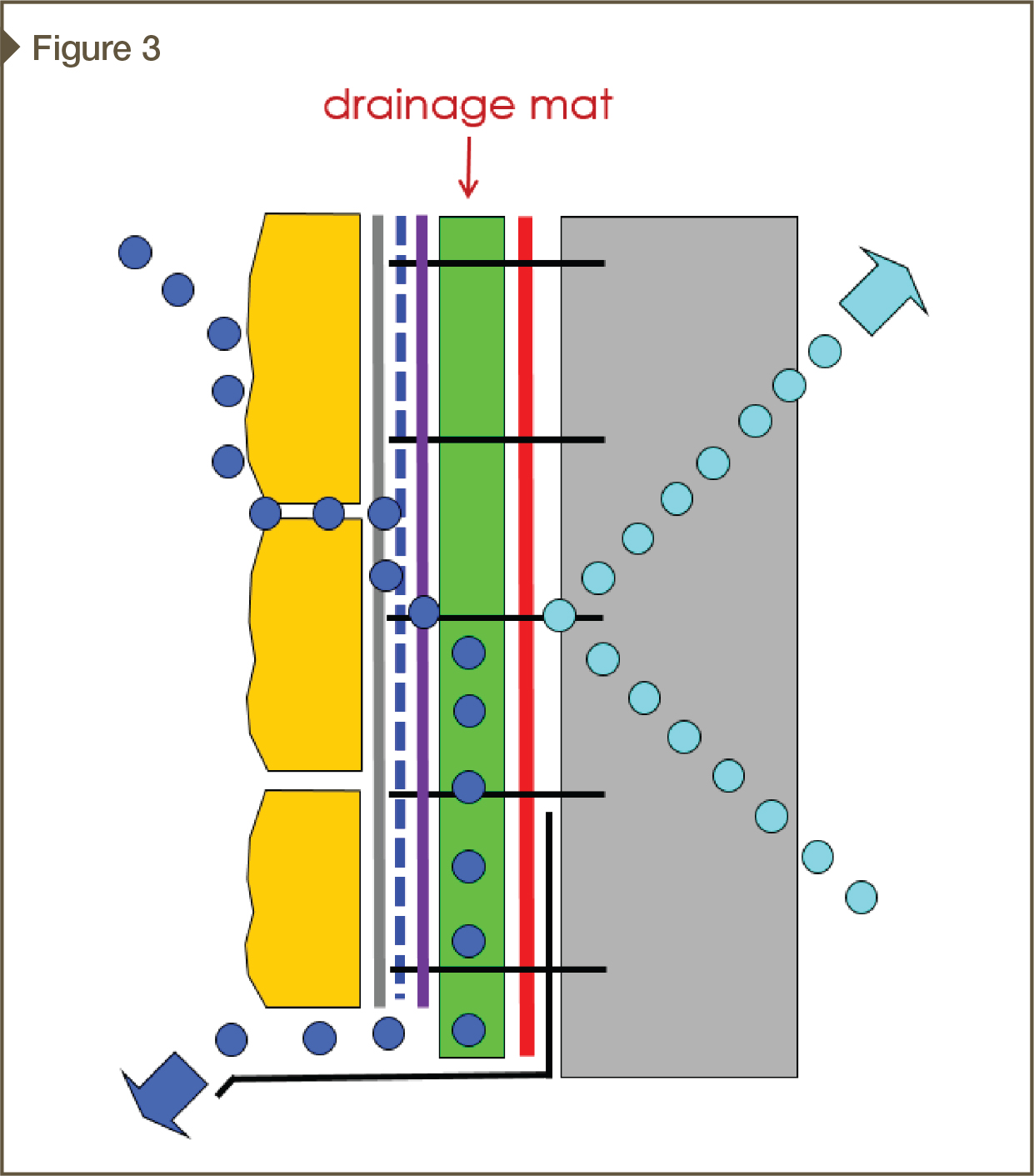

Drainage wall design strategies are the most common and effective type of adhered masonry veneer system. This approach works well in all climate zones provided there are proper water and air control layers behind the cladding. In wet climates or harsh freeze/thaw environments, it is appropriate to use a drainage wall concept with adhered masonry veneer systems that includes drainage mats or other tactics for moisture to escape the veneer system (Figure 3).

A means for drainage is a code requirement in the 2012 IBC. Some drainage walls can be upgraded to be ventilated, or even as rainscreen wall systems with weep vents low and high in wall panels.

Note 14 in the new ASTM C1780-15 states:

For optimum performance, the drainage gap shall be drained at all terminations and penetrations and ventilated at top of wall section.