UV-C basics

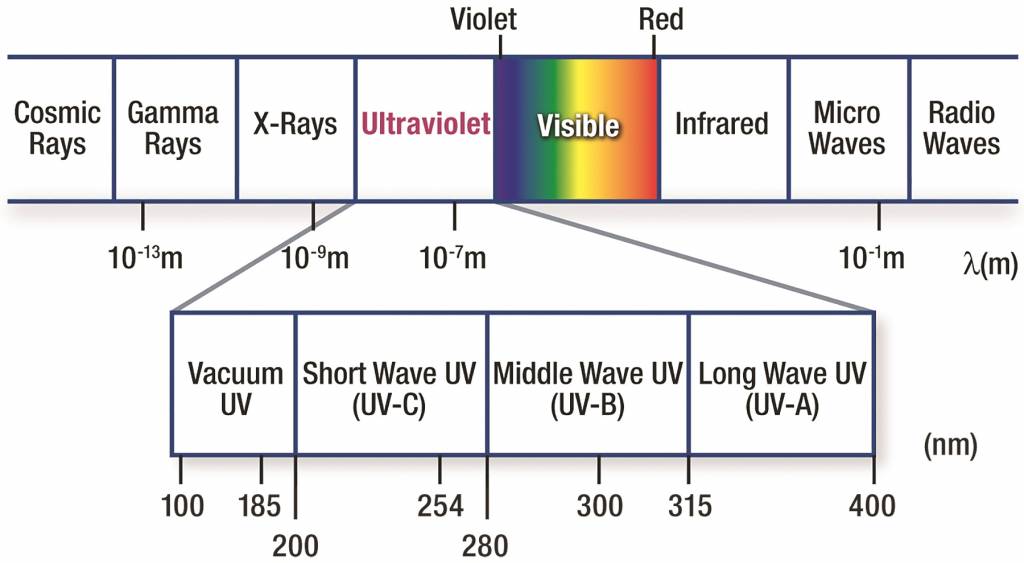

People are familiar with the harmful effects of UV from sunlight in the UV-A and UV-B wavelengths, which give rise to sunburn and the need for UV inhibitors or blocking agents (found in glasses and lotions). However, unlike UV-A and UV-B radiation, the UV-C wavelength has more electron volt energy, and is absorbed (not reflected) by all organic substances, increasing its destructiveness. Given these properties, why is there not more discussion about protecting oneself from UV-C exposure outdoors? The reason is UV-C is absorbed by the ozone layer and much of the atmosphere, and does not reach the Earth’s surface.

So how much UV-C is needed to destroy organic matter? A 2010 study commissioned by ASHRAE and the Air-conditioning, Heating, and Refrigeration Institute (AHRI) found even the most sophisticated organic compounds suffer from exposure to HVAC/R dosages of UV-C energy. As UV-C lamp installations in HVAC/R applications operate continuously, a well-distributed dose similar to visible light is all that is needed.

When it comes to worker safety, there is not specific legislation relative to UV-C exposure. However, Occupational Safety and Health Administration (OSHA) does provide guidelines. Using a ‘typical’ UV-C installation, one can reach maximum UV-C exposure in less than 10 seconds. For this reason, it is recommended any HVAC/R access point have a safety interlock switch to prevent accidental exposure to the UV-C energy inside.

UV-C lamps and lamp replacements

Modern UV-C lamps are very similar to the fluorescent lights typically found in ceiling fixtures. (Read more here.) Both lighting types operate using identical electrochemical processes. They employ an electric discharge created through argon gas striking mercury vapor to generate an invisible photon with a wavelength of 253.7 nm.

UV-C lamps differ slightly from their fluorescent counterparts in that their glass envelope must be a highly engineered shell transparent to UV-C. This allows the 253.7-nm wavelength to escape through the lamp envelope unfiltered. Fluorescent lamps use ordinary glass, which blocks the UV-C wavelength. The engineered glass is also internally coated with phosphors. The UV-C energy is contained to excite the phosphors to glow (i.e. fluoresce) in the visible light range. (Read more here.)

A typical UV-C lamp produces about 90 percent of its energy in the UV-C wavelength. Of the other 10 percent, approximately four percent energy is given up as heat, and the rest (about five percent) is in the visible light range that is medium blue (Figure 1). This color results from the argon gas in the lamp envelope (see photo).

According to most lamp manufacturers, UV-C lamps typically provide more than 80 percent of their initial output over a 9000-hour period. Such lamps should be continuously operated, the corresponding 8760 hours of a year-long 24/7 schedule fit conveniently into annual relamping schedules.

Attempting to run UV-C lamps longer than 9000 hours will produce individual lamp outages, requiring maintenance staff to monitor them routinely to know what to replace. This individual swapping out of lamps requires a larger inventory of replacements for when the lamps begin to fail in larger numbers. The replacing of a UV-C lamp is as easy as replacing a fluorescent tube above a work bench. However, they are typically in more inaccessible locations, such as the plenum of an air handler downstream of a cooling coil. Replacement costs are typically less than $0.04 per CFM.

Like fluorescent lamps, UV-C lights come in a variety of types and sizes, including single- and double-ended. The former is used in several lamp systems, some of which allow them to be inserted into the airstream through a plenum or duct, typically downstream of the cooling coil (Figure 2). Double-ended lamps have pins at both ends and are installed into specific-length fixtures, usually containing the ballast as a fluorescent fixture does. Typically, all types are available in standard- and high-output (SO and HO) configurations. The difference between the two is their watt and ballast ratings. HO lamps are usually recommended because they are less expensive on a watt-per-lamp basis.

One could also opt for encapsulated lamps, which have a transparent fluorinated ethylene propylene (FEP) coating over the glass envelope. This option hermetically seals UV-C lamps in case of breakage. Should an accident occur, broken glass and mercury will remain within the lamp.