Closing the loop: Understanding the benefits of fluid coolers

The downside of these cost comparisons is they can be arbitrary. Costs for equipment and services fluctuate around the country and around the world. Nonetheless, building owners or mechanical contractors will find a marginal difference between the total cost of purchasing and installing a system with a fluid cooler, versus a cooling tower with a heat exchanger.

The future cost savings of a system using a closed-circuit cooler begin once the system is placed into service. Arguably, the single most significant benefit of a fluid cooler, or at least the advantage most discussed, is its ability to “close the loop.”

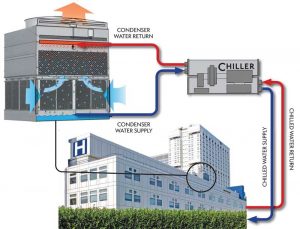

What does “closing the loop” mean? Since a cooling tower’s recirculating water, or condenser water, is open to the atmosphere, anything entering the tower from the surrounding area (e.g. leaves, pollen, dust, etc.) has the potential to enter the condenser portion of the chiller—for example, leaving the equipment vulnerable to deposition and fouling. In this example, the chiller’s condenser tubes and the fill media inside the tower are two heat transfer surfaces in an open loop tower system that does not include a heat exchanger.

Conversely, in the case of a closed-circuit fluid cooler, the condenser water loop is sealed to the atmosphere, eliminating the concern and maintenance associated with open loop systems.

Open loop tower and chiller

Figure 1 depicts a system used for a hospital cooling application. In this example, the “open loop” cooling tower is located on the roof with the condenser water piped directly to the chiller.

The equipment’s service life expectancy and heat transfer efficiency depend largely on the cleanliness of these surfaces. This requires deliberate routine maintenance, water treatment, and filtration for all operational practices to be working in perfect harmony.

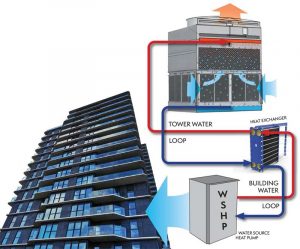

Open loop tower and heat exchanger

One strategy used by design engineers to protect the chiller or water source heat pumps (WSHPs) from contaminants within the tower’s recirculating water is to install a plate-and-frame heat exchanger between the cooling tower and chiller or WSHPs, as depicted in Figure 2.