Case study: Data Center

When TiePoint-bkm Engineering Inc. was awarded the project to design a data center in Centennial, Colorado, the senior mechanical engineer, Brian Deleon, and his team members began conducting cooling system analyses and comparing different implementation strategies. Ultimately, the driving force for their design was the city’s strict restrictions on water use—tap fees varied by size. A smaller tap would cost several hundred thousand dollars, while larger sizes would cost more than $1 million.

The following key factors were taken into consideration during the design phase:

- Colorado’s climate—mild summers and cool/

dry winters. - Water efficiency—heat rejection equipment capable of running dry.

- Plant payout—freeing up more space in the mechanical room.

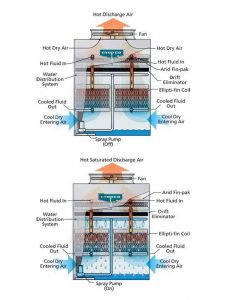

The team was able to show the owner the value of hybrid closed circuit coolers. One key factor that could not be ignored was the payback of not using water by running the coolers in dry mode.

Whether it was at night or during the colder seasons, having the flexibility to run the hybrid cooler dry provided substantial initial cost savings

by reducing the tap size for incoming city water.

In addition to increased water efficiency, the data center’s mechanical room and piping also benefited from its innovative design. The engineering firm was able to reduce the footprint of the mechanical room due to the smaller pumps and piping required by the hybrid coolers. Further, heat transfer efficiency is better protected as the entire piping system is not exposed to the atmosphere by the recirculating water.

Even in the event of a water shortage or power hit, the responsiveness of the hybrid coolers and their ability to provide cooling while running completely dry gives this critical facility more resilience in case of emergency.