Using exterior-grade waterproofing in interior applications

by jason_cramp | September 1, 2022 1:53 pm

By Makoto S. Weinstein, PE and Scott A. Tomlinson, PE

[1]

[1]Designers of new construction and renovation projects sometimes prefer to use exterior-grade waterproofing and roofing products (collectively referred to as “exterior-grade waterproofing” in this article) within interior space for improved performance compared to typical interior-grade waterproofing products. For example, improved performance may be desired in a mechanical system intake plenum that will be exposed to rain and snow that infiltrates the louver, or at some other unique interior application.

Unfortunately, the use of exterior-grade waterproofing within interior space has fire- and life-safety code implications that require analysis. If the exterior-grade waterproofing is noncombustible, the fire- and life-safety code analysis is easy. However, if it is combustible, the analysis is more complex and code requirements often constrain the waterproofing design.

A primary constraining factor is the manufacturers of exterior-grade waterproofing generally do not perform the tests required to demonstrate the fire response properties necessary to establish code compliance for interior use. The same complication exists if the designer desires to use interior-grade waterproofing products in some exterior applications, although this is not the subject of this article.

The different fire response properties and test methods required for exterior and interior applications of waterproofing products to aid designers, with a particular focus on the differences between interior (ASTM E84 and ASTM E648) and exterior (ASTM E108) fire test standards, will be explored first. The ASTM standards describe the material behavior when in contact with fire, but they are fundamentally different tests providing dissimilar fire response properties. As a result, they are not readily comparable.

A case study of a plenum design approach to navigate the code requirements to use exterior-grade waterproofing within interior space to meet the owner’s performance expectations will also be presented.

Code requirements relating to fire safety

[2]

[2]The National Fire Protection Association (NFPA) 101, Life Safety Code, International Building Code (IBC), and International Mechanical Code (IMC) are commonly adopted codes that must be considered for interior waterproofing analysis; the 2021 versions were reviewed for this article. The codes reference the following ASTM standards to determine the code required fire properties; the codes also reference similar NFPA and Underwriters Laboratories (UL) tests that are not reviewed in this article:

- E84-19A–Standard Test Method for Surface Burning Characteristics of Building Materials (IBC references 18B).

- E648-17A–Standard Test Method for Critical Radiant Flux of Floor-Covering Systems Using a Radiant Heat Energy Source.

- E108-17–Standard Test Methods for Fire Tests of Roof Coverings.

NFPA 101 Chapter 10 (Interior Finish, Contents, and Furnishings; Sections 10.2.3.3 and 10.2.7.4) and IBC Chapter 8 (Interior Finishes; Sections 803 and 804) require fire testing and classification of interior wall and floor finishes based on standards ASTM E84 and ASTM E648, respectively.

For interior walls, NFPA and IBC both require classification of the finish materials as Class A, B, or C based on flame spread and smoke developed indexes of the material when tested in accordance with ASTM E84:

- Class A–Flame spread index 0-25; smoke developed index 0-450.

- Class B–Flame spread index 26-75; smoke developed index 0-450.

- Class C–Flame spread index 76-200; smoke developed index 0-450.

For interior floors, NFPA and IBC both require classification of the finish material as Class I or II based on its critical radiant flux when testing in accordance with ASTM E648:

- Class I–Critical radiant flux of not less than 0.45 watts/cm2.

- Class II–Critical radiant flux of not less than 0.22 watts/cm2, but less than 0.45 watts/cm2.

IMC Chapter 6 (Duct Systems, Sections 602.2 and 602.2.1) provides the requirements for plenum enclosure construction materials that are exposed to the airflow. These sections generally require “Plenum enclosure construction materials that are exposed to the airflow” to “have a flame spread index of not more than 25 and a smoke-developed index of not more than 50 when tested in accordance with ASTM E84 or UL 723…” Section 602.2.1 provides exceptions for combustible materials that are fully enclosed by noncombustible enclosures and other approved materials.

NFPA 101 (various chapters) and IBC Chapter 15 (Roof Assemblies and Rooftop Structures; Section 1505) require fire testing and classification of roof coverings. Both codes require testing in accordance with ASTM E108 and classification of the roof covering as Class A, B, and C. However, ASTM E108 Classes A, B, and C are different than ASTM E84 Classes A, B, and C, as described below. Unfortunately, the similarities in classification names can lead to a misunderstanding of the intended code requirements.

Fundamental differences in ASTM E84 and E108 classifications

[3]

[3]The class rating per ASTM E84 testing is not the same as the class rating per ASTM E108 testing because the test methods are different, the flame spread results from the two tests are different, and ASTM E108 does not provide smoke developed results.

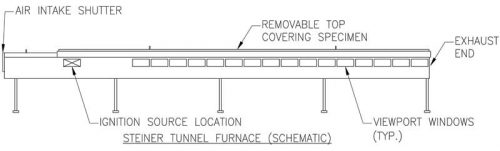

ASTM E84 (Figure 1, page 27) is a “fire-test-response standard for the comparative surface burning behavior of building materials [that] is applicable to exposed surfaces such as walls and ceilings.” It requires subjecting an approximate 7.3 m (24 ft) long by 610 mm (24 in.) wide specimen positioned face down in a chamber (ceiling position) to an ignition source at one end of the specimen for 10 minutes. The flame spread distance and smoke density are measured over time, and those measurements are used to determine the indexes. The indexes are based on comparative values to the surface flame spread and smoke density measurements with that of select grade red oak and fiber-cement board surfaces under the same fire exposure conditions.

ASTM E108 is a “fire-test-response standard that covers the measurement of the relative fire characteristics of roof coverings exposed to simulated fire sources originating outside the building.” It requires subjecting a roofing membrane to a series of fire exposure tests, including intermediate flame exposure, spread of flame, burning brand, and flying brand. The test parameters are adjusted based on the desired classification (A, B, and C). The ASTM E108 spread of flame test is like the ASTM E84 test, but the apparatus, specimen size, and required observations are different. ASTM E108 does not include a test to measure smoke density. Therefore, it does not provide fire response properties that can be used to determine flame spread or smoke developed indexes for comparison to ASTM E84 results.

Design considerations

When waterproofing is required within an interior space, a designer must determine the required or desired waterproofing performance (durability and reliability) and identify reasonable waterproofing solutions to achieve the performance.

The authors recommend starting the design process by considering waterproofing products that are intended for interior use because the manufacturers will have performed the appropriate test standards and report the required fire response properties or considering noncombustible exterior-grade waterproofing as defined by the applicable code (IBC Section 703.3). These are the simplest fire- and life-safety code compliance paths. However, these solutions will limit design options and may reduce waterproofing performance. For example, noncombustible waterproofing materials often lack the physical properties (flexibility, elongation, fastener sealability, etc.) that make combustible membranes an attractive choice for waterproofing (see the following case study).

A designer should only consider using exterior-grade waterproofing within interior space if the above-mentioned options will not meet performance expectations. In the absence of interior fire response property data from the manufacturer, a more complex analysis is required, which takes more time and effort. The analysis often requires an assessment by a qualified fire protection engineer and engagement with the authority having jurisdiction to determine if the proposed design is no less safe than what is permitted by code.

The analysis must often take into consideration local code requirements, construction type, occupancy and use of the space, occupant load, egress design, sprinkler and alarm system design, waterproofing assembly design, data from similar materials and assemblies, and other pertinent information. The designer may conclude that it does not have adequate data to perform the analysis or that the design is less safe than what is permitted by code, or the authority having jurisdiction may not agree with the analysis and not approve use of the exterior-grade waterproofing. Potential analysis approaches are beyond the scope of this article.

Designers may consider water-resistive barrier (WRB) products intended for installation within above-grade vertical wall assemblies (concealed).

Manufacturers of these products typically include ASTM E84 test data in response to code requirements for NFPA 285 assembly testing. However, these products may not be suitable for the intended interior use due to ultraviolet (UV) exposure, durability and reliability in the proposed assembly, and other reasons.

Case Study: Large HVAC plenum over interior space with exterior-grade waterproofing

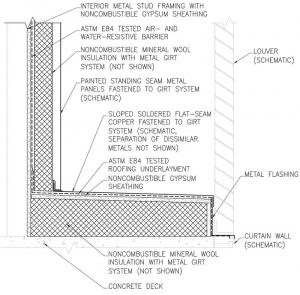

This case study provides a mostly noncombustible exterior-grade waterproofing design approach for a large HVAC “walk-in” plenum on the top floor of a building that is over interior space (Figure 2, page 28). The owner has a low tolerance for water leakage. Rain and snow can be blown and drawn through the louver during certain weather conditions, resulting in significant water accumulation on the plenum floor.

The walls are covered with standing seam steel panels over metal framing with mineral wool insulation between the framing, air- and WRB, and gypsum sheathing. The floor is covered with flat-seam soldered copper sheet metal that is sloped to drain over roofing underlayment, gypsum sheathing, and metal framing with mineral wool insulation between the framing.

The metal, insulation, and gypsum board materials are noncombustible as defined by the IBC.

The underlayment has flame spread and smoke developed indexes within permissible limits; the authors are aware of at least one underlayment product that has been tested to provide the required fire response properties necessary to establish code compliance. The metal floor framing is designed to support maintenance personnel and align with roofing attachment clip locations. The flat-seam soldered copper and standing seem steel panels have expansion joints for thermal expansion and contraction.

The IMC includes provisions that could allow the use of combustible exterior-grade waterproofing if it is fully enclosed with noncombustible materials. A project-specific analysis would be required to determine if this is acceptable.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/09/Stock-Image-Office-with-Vertical-Garden.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/09/Figure-1-interior.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/09/Figure-2-interior.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/09/Tomlinson_Headshot.jpg

- SATomlinson@sgh.com: mailto:SATomlinson@sgh.com

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/09/Weinstein_Headshot.jpg

- MSWeinstein@sgh.com: mailto:MSWeinstein@sgh.com

Source URL: https://www.constructionspecifier.com/using-exterior-grade-waterproofing-interior-applications/

[4]Scott A. Tomlinson, PE, is an associate principal with Simpson Gumpertz & Heger Inc. in Waltham, Massachusetts. His broad experience includes the design, investigation, and construction of a variety of building-enclosure systems. Tomlinson specializes in addressing construction and constructability issues and leading complex investigations. He can be reached at SATomlinson@sgh.com[5].

[4]Scott A. Tomlinson, PE, is an associate principal with Simpson Gumpertz & Heger Inc. in Waltham, Massachusetts. His broad experience includes the design, investigation, and construction of a variety of building-enclosure systems. Tomlinson specializes in addressing construction and constructability issues and leading complex investigations. He can be reached at SATomlinson@sgh.com[5]. [6]Makoto S. Weinstein, PE, is a consulting engineer with Simpson Gumpertz & Heger Inc. in Waltham, Massachusetts. He is experienced in the design, investigation, and rehabilitation of building-enclosure systems. He has more than 10 years of experience working on building wall

[6]Makoto S. Weinstein, PE, is a consulting engineer with Simpson Gumpertz & Heger Inc. in Waltham, Massachusetts. He is experienced in the design, investigation, and rehabilitation of building-enclosure systems. He has more than 10 years of experience working on building wall