Using masonry for wet flood-proofing

by sadia_badhon | January 15, 2021 7:48 pm

by Harry Lubitz, CDT

[1]

[1]There are two types of flood-proofing—dry and wet. Dry flood-proofing implies a new design for a structure or retrofit additions to an existing facility that prevents the entry of flood waters. This includes proactively avoiding lower openings or permanently sealing them, retrofitting waterproof closures to lower openings, or providing temporary waterproof membranes or barriers to block flood water intrusion. A common, last-minute dry flood-proofing technique is to wall in the structure with sand-bags, thereby blocking rising flood waters.

Wet flood-proofing, on the other hand, involves an intentional design process to allow water to enter a structure built with flood-resistant materials like masonry. The design intent is to permit flood waters to enter and exit the structure freely and enable the flood waters to rise and fall evenly inside the building in the same rate and manner as on the outside. This also implies the flood-resistant materials are a permanent part of the structure. They can be maintained to provide an attractive look before a flood event, and can also be easily restored to their original condition at minimal cost.

[2]

[2]Images © FEMA

The U.S. Department of Homeland Security through the Federal Emergency Management Agency (FEMA) provides numerous documents to assist the design and build of both dry and wet flood-proofed structures. The American Society of Civil Engineers (ASCE) 24, Flood Resistant Design and Construction, is referenced in the International Building Code (IBC), and recognized by FEMA to “meet or exceed the national minimum National Flood Insurance Program[3] (NFIP) requirements for buildings and structures.”

The U.S. Congress established NFIP in the National Flood Insurance Act (NFIA) of 1968 with the objective of providing communities and property owners cost-effective flood insurance options, guidance for floodplain management, and set design and construction standards to protect buildings constructed in special flood hazard areas (SFHAs). These regulations and standards are found in Title 44 of the U.S. Code of Federal Regulations. NFIP’s ultimate goal is to minimize and insure losses due to flood events.

NFIP creates maps to identify SFHAs[4] on the basis of a “base flood,” which is defined as a “flood that has a one-percent chance [of] being equaled or exceeded in any given year (commonly called the “100-year” flood).” These maps establish the base flood elevation (BFE). NFIP regulations require all construction below BFE use building materials that are “flood damage-resistant”.

[5]

[5]NFIP defines these materials as “any building product [material, component, or system] capable of withstanding direct and prolonged contact with floodwaters without sustaining significant damage. The term “prolonged contact” means at least 72 hours and “significant damage” refers to any damage requiring more than cosmetic repair. Cosmetic repair includes cleaning, sanitizing, and resurfacing (e.g. sanding, repair of joints, and repainting of the material). The cost of the repair[6] should also be less than the replacement of affected materials and systems.”

It is important for the specifier to pay close attention to the regulations for flood damage-resistance materials as it may have a direct impact on the structure’s ability to withstand and recover from flood damage and impact the cost of NFIP flood insurance.

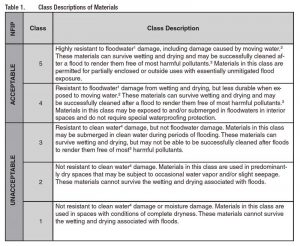

Flood damage-resistant materials are based on the five class descriptions shown in Figure 1. Virtually, all masonry materials are Class 5 flood damage-resistant materials (Figure 2). It is important to note concrete blocks can potentially act as holding vessels for floodwater should the exterior skin be breached. This would make it difficult or impossible to clean the blocks. Therefore, design professionals should take great care in specifying a water-resistant envelope for concrete blocks used in various wet flood-proofing activities.

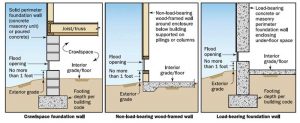

Solid elevated walls

As masonry has been identified as a flood damage-resistant material, it is optimal for elevating a structure above BFE. Figure 3 shows options—two of which are masonry—to meet the minimum requirements if the lowest floor is at BFE. The foundation wall is typically extended to the height of a full story, which could be higher than the BFE, to create storage or parking areas. These elevated walls provide a consistent look with other structures in the area. While it is required to use flood damage-resistant materials below BFE, the author strongly recommends employing the same material on any construction below the lowest floor.

[7]

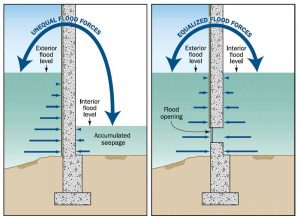

[7]Use of these wall systems requires the addition of a flood opening to equalize the water pressure and hydrostatic forces created by standing or slow rising and falling water (Figure 4). The flood opening will work to equalize the pressure on each side of the wall and protect it from damage or collapse.

Masonry has an advantage over the wood-framed, nonloadbearing option illustrated in Figure 3 because of its ability to support the weight of the structure during the ebb and flow of hydrostatic loads. Further, masonry provides the additional advantages of fire and water resistance.

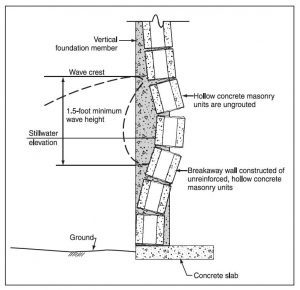

Breakaway walls

Breakaway walls are typically preferred when the hydrodynamic loads are more than 3 m (10 ft) per second or there is a risk of impact from waves or debris. These walls are often built to create enclosed storage areas below BFE or enclose the entire structure within the exterior pilings or columns, which is similar to creating a first-floor, secure parking structure for a high-rise building.

[8]

[8]Breakaway walls are constructed with unreinforced masonry units and are expected to fail at the mortar joints between the masonry units, beginning near the stillwater elevation where the pressure on the wall is greatest (Figure 5). As a wave of water hits the breakaway wall with no less than 69 kPa (10 psi) and no more than 138 kPa (20 psi) of force, the wall will collapse and allow the water to flood the enclosed area without washing away the entire building.

Floodable ground-level interior space

In low floodplain areas, the intent may be to expect regular flooding and design usable space to tolerate it. The subsequent case study highlights this rising trend of moving living and working spaces, equipment, and other amenities up one or more floors in the building from ground level.

Again, masonry units can provide structural support, partitions, storage areas, entryways, and easy exterior excess to convert floodable space into functional areas. All interior masonry units must be designed to withstand hydrostatic pressure of rising waters. They can be easily cleaned after the floodwaters recede.

[9]

[9]Case study

The Medical University of South Carolina (MUSC) Shawn Jenkins Children’s Hospital and Pearl Tourville Women’s Pavilion is the newest medical facility in Charleston, South Carolina. The $390-million, 57,971-m2 (624,000-sf) building is 11 stories tall, 20 percent larger than the facility it replaced. More than 200 care team members, MUSC leaders, administrators, and almost 30 family members collaborated with architecture firms Perkins + Will (New York) and McMillan Pazdan Smith (Charleston) to design this facility.

However, one of the most significant challenges in the design was the lower Charleston location. Barely 3 m (11 ft) above sea level, the site regularly experiences tidal flooding. A consistent parade of weather events, including hurricanes, has pummeled the city with major tidal surges. The city is surrounded by water on three sides, so buildings professionals incorporate flood-proofing into all new designs. Consequently, the entire first floor of this new facility is built to withstand flooding and constructed out of concrete masonry units. To protect the block walls from degradation during flooding, design professionals chose a latex-based cold fluid-applied waterproof coating for the first floor. The coating was chosen because it is known to withstand hydrostatic pressure, is semi-impermeable, cost-effective, easy to apply and procure, and could be tinted to their color scheme.

It is imperative specifiers not just account for the flood damage-resistance functionality of the masonry unit, but offer options to waterproof, weatherize, and beautify the material. The three elements—waterproof, weatherize, and beautify—have specific performance requirements and reference tests that must be included in the specification.

[10]

[10]Photos courtesy UGL

Waterproof

To resist the hydrostatic loads imposed on the masonry and assure water does not get into the block cavity, all exposed surfaces of the masonry unit need to be coated with a penetrating waterproofing coating. Traditional paints and/or block-fillers are not designed or tested to meet hydrostatic loads. Specific cold-fluid applied waterproofing products have been tested to ASTM D7088, Standard Practice for Resistance to Hydrostatic Pressure for Coatings Used in Below Grade Applications Applied to Masonry. As the masonry unit may be installed above-grade in wet flood-proofing applications, ASTM D7088 tests the psi hold back capabilities of the coating on the masonry unit, and is the best reference test in this case. Every foot of water exerts 3 kPa (0.43 psi) of pressure on the coating. Consequently, to protect a 3-m (10-ft) high block wall, the coating would have to resist a minimum of 30 kPa (4.3 psi). Obviously, the taller the wall of water the greater the psi hold back requirement.

Weatherize

While these masonry units are in place they will receive a daily bombardment of natural elements. In order to be prepared to function in their waterproofing role, they must be protected when they are ‘off-duty.’ Three specific environmental forces will work on the masonry unit while it stands guard, particularly in coastal areas—wind-driven rain, salt spray, and ultraviolet (UV) resistance.

ASTM D6904, Standard Practice for Resistance to Wind-driven Rain for Exterior Coatings Applied on Masonry, measures the resistance to wind-driven rain in miles per hour. Unfortunately for hurricane-prone areas, this is a “pass/fail” test that simulates the “equivalent dynamic pressure at [158 km/h] 98 mph wind velocity.” This velocity is just over the wind speed of a Category 1 sustained wind on the Saffir-Simpson Hurricane Wind Scale. Specifiers need to consult their waterproof coating manufacturer in order to ascertain if they can provide a product recommendation with modified testing to simulate the higher wind-driven rain speeds that may be relevant to their project. It is important to remember the coating must resist wind speeds so it does not blow off, and be ready for potential flood waters. Removal of the coating would render the masonry unit susceptible to intrusion by wind-driven rain (or subsequent flood waters) into the cavity, making them “difficult or impossible to clean.”

[11]

[11]ASTM B117, Standard Practice for Operating Salt Spray (Fog) Apparatus, has been the benchmark test for corrosion since its initial publication in 1939. Recently, it was replaced with ASTM D5894, Standard Practice for Cyclic Salt Fog/UV Exposure of Painted Metal, (Alternating Exposures in a Fog/Dry Cabinet and a UV/Condensation Cabinet). The incorporation of UV radiation and condensation cycles into the cyclical salt-spray test provides the best real-world test for evaluating the performance of a coating system. It should be the reference standard for building professionals.

Beautify

The final step is enhancing the building’s aesthetics with a wide color palette while meeting NFIP’s cosmetic repair objective for easy cleaning, sanitizing, and resurfacing. Latex-based cold fluid-applied waterproofing membranes provide high flexibility in color tinting. They can also be top-coated with good quality latex paint for color without losing their waterproofing attributes. They are easy to apply and can also be cleaned and resurfaced at minimal cost.

It is important to note that if the waterproof coating was penetrated, say from a strike from an object or vehicle, and the block was fractured, the waterproof integrity of the wall would be breached.

Conclusion

Properly waterproofed and protected masonry units allow designers and specifiers to meet the requirements of NFIP, and create wet flood-proofed buildings that will weather the elements and protect occupants and owners from excessive flood losses. For centuries we have built near bodies of water for their commercial and aesthetic value. As seas rise, natural disasters become more frequent, and storm repair costs increase, masonry stands as one of the best flood damage-resistant building material options.

[12]Harry J. Lubitz, CSI, CDT, is the architectural sales director for UGL – United Gilsonite Laboratories, Inc. Lubitz has more than 40 years of experience in the building materials industry and is active in numerous architectural and professional organizations including CSI, IIBEC, and ASTM. He has also served as an adjunct faculty member at Lord Fairfax Community College in Virginia. Lubitz can be reached at harry.lubitz@ugl.com[13].

[12]Harry J. Lubitz, CSI, CDT, is the architectural sales director for UGL – United Gilsonite Laboratories, Inc. Lubitz has more than 40 years of experience in the building materials industry and is active in numerous architectural and professional organizations including CSI, IIBEC, and ASTM. He has also served as an adjunct faculty member at Lord Fairfax Community College in Virginia. Lubitz can be reached at harry.lubitz@ugl.com[13].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/01/MUSC-15.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/01/fema_tb_2_flood_damage-resistant_materials_requirements_PG6.jpg

- National Flood Insurance Program: https://www.fema.gov/flood-insurance

- identify SFHAs: https://www.fema.gov/sites/default/files/2020-07/fema_tb_2_flood_damage-resistant_materials_requirements.pdf

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/01/fema_tb_2_flood_damage-resistant_materials_requirements_PG9.jpg

- cost of the repair: http://www.fema.gov/sites/default/files/2020-07/fema_tb_2_flood_damage-resistant_materials_requirements.pdf

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/01/fema_tb1_openings_foundation_walls_walls_of_enclosures_031320_PG2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/01/fema_tb1_openings_foundation_walls_walls_of_enclosures_031320_PG1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/01/fema_tb_9_PG14.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/01/MUSC-14.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/01/MUSC-12.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/01/Lubitz-Photo.jpg

- harry.lubitz@ugl.com: mailto:harry.lubitz@ugl.com

Source URL: https://www.constructionspecifier.com/using-masonry-for-wet-flood-proofing/