Using plenum barriers to comply with sound isolation requirements

Improving sound-isolation performance

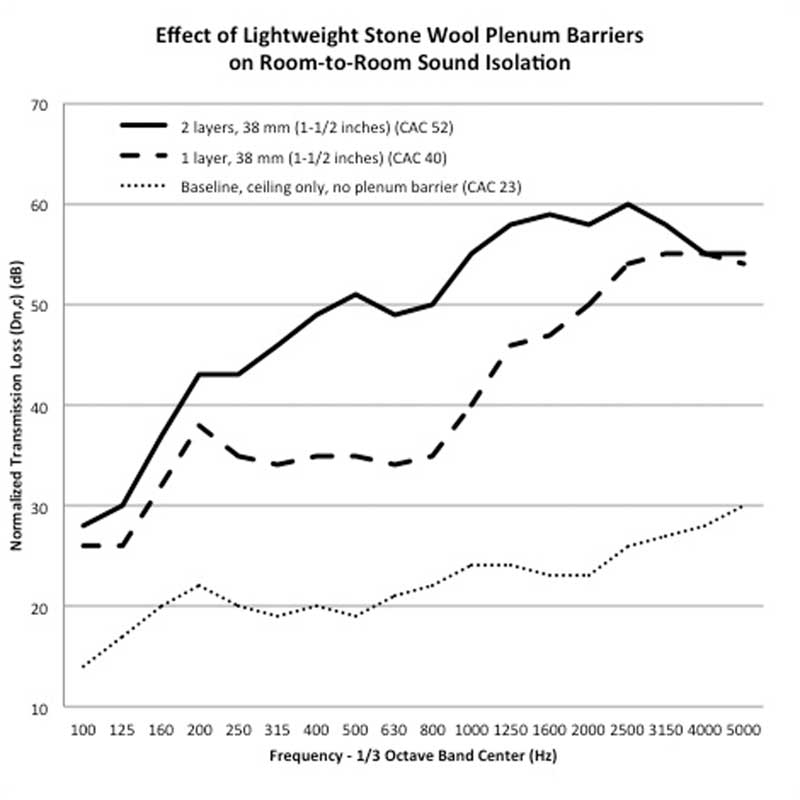

Figure 4 shows the improvement in sound-isolation performance when single- and double-layer stone wool plenum barriers are combined with a standard, stone wool ceiling relative to the performance of the ceiling alone. The combination of the ceiling and single-layer plenum barrier performed at CAC/STC 40—a 17-point increase over the ceiling alone—and would comply with STC 40 requirements in acoustic standards.

This type of plenum barrier would typically be used over a demising wall containing the door(s) into the room, demountable partitions, or significant areas of single-pane glass. These elements would be the weakest link in the sound-isolation system. Upgrading the plenum barrier above these walls would not likely improve the perceived sound isolation in that particular direction.

The combination of the ceiling and double-layer plenum barrier performed at CAC/STC 52—a 27- point increase over the ceiling. It would comply with STC 45 and 50 requirements in relevant acoustic standards. This type of plenum barrier would most typically be used over heavier demising walls without weaker components such as doors and glass.

When comparing the double-layer plenum-barrier test results of this phase to those from prior phases of the research program, the air space between the plenum-barrier layers was found to increase the performance substantially. Single-layer, monolithic slabs of stone wool—some with foil facings on both sides—with total thickness greater than that of the two thinner layers combined performed significantly worse than a double-layer plenum barrier of thinner material and an interstitial airspace. The findings from this phase of the research program also showed decreasing the plenum barrier material from 38 to 25 mm (1 ½ to 1 in.) in thickness can still achieve isolation values of CAC/STC 40 and 45, but not CAC 50 as required by some standards.

During testing, the 25-mm (1-in.) thick plenum-barrier material was more difficult to handle because it was too thin to hold with one hand. There was a sense the material might tear unless held vertically with two hands. On a construction site, it might be confusing to contractors to have both 25- and 38-mm (1- and 1 ½-in.) thick materials that need to be installed in different rooms. A uniform plenum-barrier thickness of 38 mm (1 ½ in.) is advisable for acoustic performance and accurate installation.

For optimal results

The foil facing on the plenum barrier material improves acoustic performance significantly—seven to 10 points, depending on whether the plenum barrier is single- or double-layer. A double-layer plenum barrier cannot even achieve the CAC/STC 45 level of sound isolation without the foil facing. Only plenum-barrier material with a foil facing should be used when CAC/STC 40, 45, and 50 levels of sound isolation are desired between rooms. Substitutions of unfaced materials will likely not result in the desired performance.

Covering the vertical seams between plenum-barrier panels with metal tape may not be necessary from an acoustic performance perspective. Adding the tape over the seams did not increase wideband CAC or one-third octave band transmission loss. However, taping the vertical seams between the plenum barrier panels tied all of the pieces together into a system that appeared to be more durable and professionally installed. Covering the seams with tape also may help acoustic performance or durability on actual project sites if gaps occur between panels, or if the plenum barriers are penetrated by structural or mechanical elements within. Caulking the plenum barriers is generally not required, but might be considered by installing contractors in limited locations if a large gap is observed.

Conclusion

Historically, running an acoustic ceiling continuously above partial-height demising walls was believed to lead automatically to poor acoustic performance and noncompliance with user expectations and standards. The findings from the current phase of the Optimized Acoustics Research Program show it is possible to achieve high levels of sound isolation between rooms by employing common, stone wool acoustic ceilings combined with plenum barriers—even when the suspended, modular ceiling grid runs continuously above the partial-height demising walls.

The design approach and installation method defined in this research can lead to compliance with acoustic standards, guidelines, and building rating systems requiring STC 40, 45, and 50 levels of isolation. Specifiers, designers, and building owners can use these findings to optimize acoustic performance when a continuous ceiling is desired and full-height walls are not possible.

Gary Madaras, PhD, Assoc. AIA, is an acoustics specialist at Rockfon. He helps designers and specifiers select the appropriate acoustical ceiling products and apply them effectively. Madaras is a member of the Acoustical Society of America (ASA), Canadian Acoustical Association (CAA), and Institute of Noise Control Engineering (INCE). He authors technical articles and speaks publicly on the topic of optimizing acoustic experiences. Madaras can be reached at gary.madaras@rockfon.com.