Using plenum barriers to comply with sound isolation requirements

by Katie Daniel | May 31, 2017 2:44 pm

[1]

[1]by Gary Madaras, PhD, Assoc. AIA

Sound isolation between rooms can be important for speech privacy. For example, in patient exam rooms in a medical building, conversations between patients and their doctors are meant to be confidential; similarly, discussions in an enclosed office between a human resources (HR) director and an employee are meant for no one else. Even when speech privacy is not a concern, sound transmitting from one room into another can be annoying or distracting and can inhibit productivity, concentration, and relaxation.

Achieving sound isolation between rooms relates to the overall construction of those spaces’ envelopes, including the walls, floors, windows, doors, and sometimes ceilings. The overall level of sound isolation often depends on the weakest link in the construction.

Acoustics requirements in building standards, guidelines, and rating systems list sound transmission class (STC) most frequently as the sound-isolation metric. STC requirements generally range from 40 to 50, with STC 45 being the most commonly occurring requirement for interior construction when sound isolation is needed. (For more, see this author’s “A Guide on the Four Categories for Acoustics Criteria in Building Standards and Guidelines,” which was published in the July−September 2016 edition of Acoustical Interior Construction.) Demising walls are required to be full-height—from structural floor slab to structural floor slab or roof, with any penetrations sealed airtight.

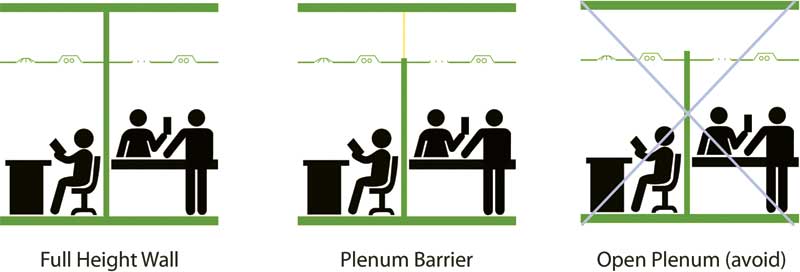

As a cost-saving measure in some buildings, interior walls are instead stopped at the height of a suspended, modular acoustic ceiling. They do not extend full-height up to the structural floor slab or roof. This practice not only saves on the construction cost of the walls, but also creates a continuous open space above the suspended ceiling that can be used as a return-air plenum.

[2]

[2]Specifying a plenum to return air can save money, compared with the cost of adding rigid metal return-air ductwork above the ceiling. This design approach typically does not comply with minimum sound-isolation performance requirements in standards, guidelines, and rating systems because sound can transmit at higher levels through the lightweight acoustic ceiling and over the partial-height wall. Some designers and building owners still elect to use this approach for the cost savings.

Effects of noise flanking paths

Eliminating the need to choose between a design approach that works acoustically and one that

works financially was one of the motivations for the Optimized Acoustics Research Program, an ongoing, multi-year, multi-organization investigation into cost-effective means of designing and constructing interior architecture that complies with the acoustic requirements in industry standards, guidelines, and building rating systems. (For more, visit www.optimizedacoustics.com[3]. The current program includes manufacturers and a material testing laboratory; membership will vary in the future according to the topics being investigated. The initiative began in 2014, and progress updates of the findings, such as this article, have been presented at and published in the proceedings of InterNoise, NoiseCon, and Acoustics Week Canada, as well as published in Sound & Vibration and Canadian Acoustics.) An early phase of this initiative investigated the effects of noise flanking paths, or ‘leaks,’ through penetrations in the ceiling system when the demising walls stop at the height of the ceiling instead of extending full-height.

Suspended, modular ceiling systems typically have recessed light fixtures, open return-air grilles, supply air diffusers, and other miscellaneous penetrations for sprinkler heads, loudspeakers, security/surveillance devices, and Wi-Fi devices. These openings and penetrations in the ceiling system create noise flanking paths, through which noise transmits more easily between rooms.

The existence of these noise flanking paths is well-known in the architectural acoustics industry. Previous studies by the National Research Council of Canada (NRC) concluded even if ceiling panels with high transmission loss are used, the attenuation between rooms is limited by such leaks. (R.E. Halliwell and J.D. Quirt’s “Controlling Interoffice Sound Transmission through a Suspended Ceiling,” which appeared in the September 1991 issue of the Journal of Acoustical Society of America, has more information.)

The findings of this earlier phase of the research program showed typical noise flanking paths in a suspended acoustic ceiling (caused by penetrations for lights and air-distribution devices alone) decreased ceiling attenuation class (CAC) by 10 points. (A piece co-written by this article’s author and A. Heuer, “Effects of Noise Flanking Paths on Ceiling Attenuation Class [CAC] Ratings of Ceiling Systems and Inter-Room Speech Privacy,” was part of the Proceedings of Inter-Noise 2015, edited by Courtney Burroughs and George Maling.) CAC is the acoustic metric quantifying the ceiling panel’s sound-blocking performance when the demising wall stops at the height of the ceiling. A 16-mm (5/8-in.) thick mineral fiber ceiling panel tested at CAC 37, but when four lights, one supply diffuser, and one return-air grille were added to the ceiling system, the value decreased to CAC 27. More importantly, the decrease in performance was not consistent across all frequencies.

[4]

[4]High-frequency isolation (i.e. 1000-Hz octave band and higher), which is more relevant to whether or not speech is intelligible, decreased by 15 to 22 dB. Therefore, ‘CACpanel’ must be differentiated from ‘CACsystem’—the former being what is tested and reported by manufacturers for their ceiling panels, and the latter being how the whole ceiling system with common penetrations actually performs.

While noise flanking paths through ceiling systems can be remediated at times, the noise-control measures required to do so are often labor-intensive (and therefore costly) and can prevent practical access to the ceiling plenum. (See “Optimizing Ceiling Systems and Lightweight Plenum Barriers to Achieve Ceiling Attenuation Class [CAC] Ratings of 40, 45, and 50,” written by the same authors in note 4. It was part of Proceedings of Noise-Con 2016−Revolution in Noise, edited by Burroughs and Gordon Ebbitt.) Figure 1 illustrates the noise-control measures used during this early phase of testing to increase CACsystem to equal CACpanel.

Reducing sound transmission

The Building Science Branch of the Alberta Public Works, Supply, and Services has conducted extensive research on sound isolation between offices with suspended ceilings. (For more, read K. Kruger’s piece, “The Effect of Various Parameters on the Sound Isolation between Offices with Suspended Ceilings,” from Canadian Acoustics [16 (2)]

in 1988.) It states attempting to match

the isolation performance of a ceiling to that of the demising wall can lead to disappointing results. It is important to know the combined effect of the wall, ceiling system, and any flanking that might be introduced through the ceiling.

[5]

[5]Another conclusion is the most effective method of reducing sound transmission through the ceiling is to introduce a barrier into the plenum (Figure 2). The plenum barrier can be limited in length. It only has to be positioned above the demising wall between the two adjacent rooms, and does not need to extend around the entire perimeters. This would allow return air to still flow freely through the plenum.

When plenum barriers do need to surround the room’s entire perimeter, a hole of the appropriate size based on air volume and desired velocity should be cut in the plenum barrier over the door into the room. Unless the door is heavy, with gaskets, and acoustically rated at STC 40 or above, it will likely transmit more noise than the return-air opening in the plenum barrier above the ceiling.

[6]

[6]Stone wool plenum barriers

Plenum barriers can be constructed of a variety of different lightweight materials, including:

- limp, mass-loaded vinyl (MLV);

- stone wool insulation with a foil facing;

- standard gypsum wall board; or

- some combination of these materials.

This article omits research done on MLV plenum barriers because they generally do not perform as well as stone wool insulation and gypsum-board plenum barriers; further, plenum-rated MLV is much more costly than stone wool insulation and gypsum board. Additionally, the MLV plenum barriers are more time-consuming to install.

While gypsum-board plenum barriers are just as cost-effective as stone wool plenum barriers and perform as well acoustically, the rigidity of the material can be a disadvantage in some buildings where there is floor/roof deflection, seismic joints, or expansion/contraction joints. This article focuses on stone wool plenum barriers due to their low cost, relatively quick installation, pliability, and high sound-isolation performance, but other materials may prove to be appropriate in some applications.

The goals of this most current phase of the research were twofold. First, the objective was to test whether stone wool plenum barriers could achieve the high sound-isolation ratings that are required by acoustic standards. Secondly, the mission was to determine whether the plenum barriers could be simplified to decrease material cost or installation time. The test series investigated if the thickness/weight of the plenum barrier could be decreased, if the foil facing could be eliminated, and if taping the vertical seams between plenum barrier panels could be eliminated.

A series of sound-isolation tests was performed on a suspended, modular, acoustic ceiling system with and without various lightweight plenum barriers under laboratory conditions in a dual-room chamber. For the baseline test, the specimen comprised a metal suspension grid filled with ceiling panels, but no plenum barrier above the demising wall. Subsequent tests added various lightweight plenum barriers. In all cases, the ceiling grid ran continuously (uninterrupted) over the top of the laboratory’s central demising wall.

A senior test engineer performed all tests at NGC Testing Services (Buffalo, New York). The laboratory is accredited by the National Voluntary Laboratory Accreditation Program (Laboratory Code 200291-0). Tests were performed according to ASTM E1414, Standard Test Method for Airborne Sound Attenuation Between Rooms Sharing a Common Ceiling Plenum, and ASTM E413, Classification for Rating Sound Insulation.

Figure 3 shows the single- and double-layer stone wool plenum barriers being installed in the laboratory for testing. The stone wool material was 38 mm (1 ½ in.) thick with a density of 128 kg/m3 (8 pcf) and surface weight of 4.88 kg/m2 (1.5 psf).

[7]

[7]For most of the tests, the plenum barrier panels had a fiber-reinforced foil facing on one side. When the double-layer plenum barriers were tested, the foil was oriented toward the open ceiling plenum—not into the small, interstitial airspace between the two layers. The plenum barriers were mechanically fastened along the top edge using common, self-tapping, sheet metal screws with insulation washers into a common 41-mm (1 5/8-in.) wide metal channel attached to the test chamber overhead slab. Screws were spaced approximately 305 to 457 mm (12 to 18 in.) on center (o.c.). Typically, each 610-mm (24-in.) panel had two screws along the top. The bottoms of the plenum barriers were only friction-fitted against the top track of the demising wall and the grid. They were not mechanically fastened, glued, or caulked. No neoprene gaskets (as seen in some project-specific plenum barrier details) were used.

Each panel was abutted to the adjacent panels along the sides with no overlap. For some tests, the vertical seams between adjacent panels were taped using 50-mm (2-in.) wide metal tape for sealing butt-joints. When the double-layer plenum barriers were tested, the 610-mm (24-in.) wide panels were staggered 305 mm (12 in.) so the seams were not aligned. This required a small cut along the bottom of one layer of the plenum barrier panels so they could slide down over the grid bulb and allow the bottom of the plenum barrier panel to sit on the top track of the demising wall.

No caulk or sealant was used. Small gaps around and between some of the plenum-barrier panels were visible. Most gaps were closed during installation due to the pliability of the stone wool. The panels were cut slightly oversized and then compressed vertically and laterally during installation, which helped prevent gaps.

[8]

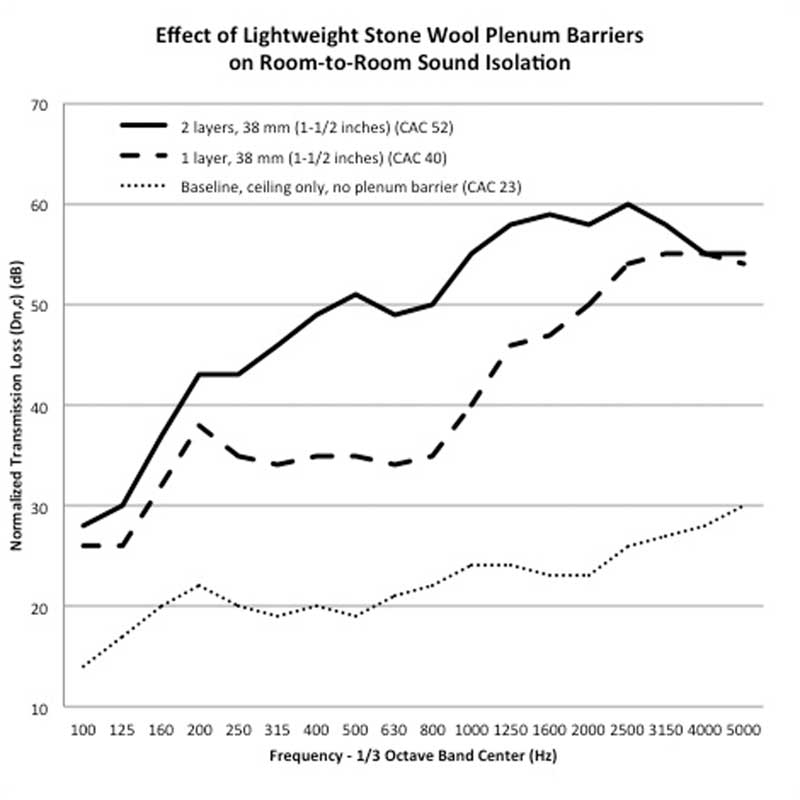

[8]Improving sound-isolation performance

Figure 4 shows the improvement in sound-isolation performance when single- and double-layer stone wool plenum barriers are combined with a standard, stone wool ceiling relative to the performance of the ceiling alone. The combination of the ceiling and single-layer plenum barrier performed at CAC/STC 40—a 17-point increase over the ceiling alone—and would comply with STC 40 requirements in acoustic standards.

This type of plenum barrier would typically be used over a demising wall containing the door(s) into the room, demountable partitions, or significant areas of single-pane glass. These elements would be the weakest link in the sound-isolation system. Upgrading the plenum barrier above these walls would not likely improve the perceived sound isolation in that particular direction.

The combination of the ceiling and double-layer plenum barrier performed at CAC/STC 52—a 27- point increase over the ceiling. It would comply with STC 45 and 50 requirements in relevant acoustic standards. This type of plenum barrier would most typically be used over heavier demising walls without weaker components such as doors and glass.

When comparing the double-layer plenum-barrier test results of this phase to those from prior phases of the research program, the air space between the plenum-barrier layers was found to increase the performance substantially. Single-layer, monolithic slabs of stone wool—some with foil facings on both sides—with total thickness greater than that of the two thinner layers combined performed significantly worse than a double-layer plenum barrier of thinner material and an interstitial airspace. The findings from this phase of the research program also showed decreasing the plenum barrier material from 38 to 25 mm (1 ½ to 1 in.) in thickness can still achieve isolation values of CAC/STC 40 and 45, but not CAC 50 as required by some standards.

During testing, the 25-mm (1-in.) thick plenum-barrier material was more difficult to handle because it was too thin to hold with one hand. There was a sense the material might tear unless held vertically with two hands. On a construction site, it might be confusing to contractors to have both 25- and 38-mm (1- and 1 ½-in.) thick materials that need to be installed in different rooms. A uniform plenum-barrier thickness of 38 mm (1 ½ in.) is advisable for acoustic performance and accurate installation.

For optimal results

The foil facing on the plenum barrier material improves acoustic performance significantly—seven to 10 points, depending on whether the plenum barrier is single- or double-layer. A double-layer plenum barrier cannot even achieve the CAC/STC 45 level of sound isolation without the foil facing. Only plenum-barrier material with a foil facing should be used when CAC/STC 40, 45, and 50 levels of sound isolation are desired between rooms. Substitutions of unfaced materials will likely not result in the desired performance.

Covering the vertical seams between plenum-barrier panels with metal tape may not be necessary from an acoustic performance perspective. Adding the tape over the seams did not increase wideband CAC or one-third octave band transmission loss. However, taping the vertical seams between the plenum barrier panels tied all of the pieces together into a system that appeared to be more durable and professionally installed. Covering the seams with tape also may help acoustic performance or durability on actual project sites if gaps occur between panels, or if the plenum barriers are penetrated by structural or mechanical elements within. Caulking the plenum barriers is generally not required, but might be considered by installing contractors in limited locations if a large gap is observed.

Conclusion

Historically, running an acoustic ceiling continuously above partial-height demising walls was believed to lead automatically to poor acoustic performance and noncompliance with user expectations and standards. The findings from the current phase of the Optimized Acoustics Research Program show it is possible to achieve high levels of sound isolation between rooms by employing common, stone wool acoustic ceilings combined with plenum barriers—even when the suspended, modular ceiling grid runs continuously above the partial-height demising walls.

The design approach and installation method defined in this research can lead to compliance with acoustic standards, guidelines, and building rating systems requiring STC 40, 45, and 50 levels of isolation. Specifiers, designers, and building owners can use these findings to optimize acoustic performance when a continuous ceiling is desired and full-height walls are not possible.

Gary Madaras, PhD, Assoc. AIA, is an acoustics specialist at Rockfon. He helps designers and specifiers select the appropriate acoustical ceiling products and apply them effectively. Madaras is a member of the Acoustical Society of America (ASA), Canadian Acoustical Association (CAA), and Institute of Noise Control Engineering (INCE). He authors technical articles and speaks publicly on the topic of optimizing acoustic experiences. Madaras can be reached at gary.madaras@rockfon.com[9].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/05/BDG-Architects-39-copy.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/05/UK-Morriston-Hospital20074.jpg

- www.optimizedacoustics.com: http://www.optimizedacoustics.com

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/05/Fig1_edit.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/05/Figure2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/05/RF_Jacob-Storre205-copy.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/05/Fig3_edit.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/05/Figure4.jpg

- gary.madaras@rockfon.com: mailto:gary.madaras@rockfon.com

Source URL: https://www.constructionspecifier.com/using-plenum-barriers-to-comply-with-sound-isolation-requirements/