Metal buildings

While pre-cured silicone sealants have been used for many years in various building envelope restoration applications, they have recently been employed by some forward-thinking manufacturers and erectors in the metal building industry. There are many features of pre-cured sealants that make them ideal for various metal building-related applications. Their flexibility and high movement capability make them perfect for sealing areas experiencing a significant amount of thermal expansion and contraction—a situation commonly found in metal building and roofing applications.

The UV stability keeps pre-cured silicone sealants from degrading under the intense, long-term exposure to weather and the elements routinely found in these applications. One of the most important features of these sealants for metal building applications is no mechanical fasteners are required. The adhesive’s ‘green strength’ (i.e. the holding strength of the un-cured adhesive) secures the pre-cured sealants in place during cure. This enables them to be installed with no other means of attaching the material to the substrate, even on a vertical surface. Therefore, installation of pre-cured sealants is quick and efficient, particularly when compared to other materials commonly used in these and similar applications.

For example, all-metal or other ‘membrane’ sealants generally require many mechanical fasteners (up to 1500 per 30.5 m [100 ft] of material), often in addition to sealants and/or mastics. The large amount of fasteners dramatically increases the time and labor cost required for installation of these systems. Additionally, since every fastener creates another hole in the roof, the potential for leaks increases.

Pre-cured sealant systems are being successfully installed in many different applications within the metal buildings industry, including:

- expansion joints;

- roof-to-wall transitions (Figure 3);

- roof height change details;

- joints between new and existing buildings;

- roof gutter seams;

- ridge applications;

- roof penetrations;

- roof-curb seals; and

- miscellaneous repair applications.

Another important advantage of using pre-cured sealants in metal building applications is the adhesives typically bond strongly to metal substrates without use of a primer. When using neutral-cure silicone adhesive, such as oxime—or alcohol-based cure systems—as opposed to acetoxy or acid-cure adhesive systems, which give off a vinegar-like smell during cure—as recommended by manufacturers, the adhesive’s compatibility with metal building materials is not a concern.

Pre-cured sealants are commonly used in various metal building repair applications, often related to metal roofing. Some of these include the repair of holes in roof decking and of failed standing seams.

Storage bins

Another area of application for pre-cured sealants is large storage containers, such as grain storage bins. These require a watertight design to keep the contents dry and isolated from insects and other animals. Pre-cured sealants’ flexibility, along with their resistance to the weather and ability to adhere to various substrates, makes them suitable for use in applications relating to storage bin sealing. Pre-cured sealants can be used for:

- sealing between the storage bin and the concrete support slab;

- wall-to-roof joints;

- sealing around openings and penetrations; and

- gaskets for openings and bin access points.

Sealing the bottom of the storage bin typically requires a bond to both the steel wall of the bin and the concrete support slab. The ability of pre-cured sealant systems to bond to various types of substrates, including steel, concrete, and many others, is a significant advantage for these products in storage container applications.

Residential applications

Many of the same attributes making pre-cured sealants an excellent choice for various commercial and industrial applications also allows them to perform effectively in residential applications. Pre-cured sealants can be used in sealing areas such as windows, skylights, roofing, HVAC, and many other household applications.

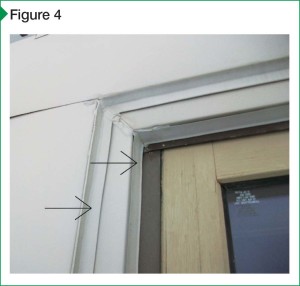

Figure 4 shows pre-cured sealants installed in a residential window application. In this particular application, the pre-cured sealant is installed in two different areas of the window system where the existing sealant and gasket material have failed, causing water leaks at these areas. Both of these installation areas are corners, which demonstrate the flexibility of pre-cured sealants, as well as their ability to be installed in various configurations. This application is an example of where notched pre-cured sealants can be bent into different shapes and installed in areas such as corners, window mullions, and other difficult-to-seal applications. As shown in Figure 4, pre-cured sealants can be color-matched, allowing them to blend in well with the substrate.

In addition to sealing leaks and keeping homes watertight, pre-cured sealants can also be very beneficial because of their capacity to stop air leaks. Sealing these leaks is a critical part of reducing heating and cooling losses and, thus, decreasing the overall energy use and costs associated with the home.