Using pre-cured sealants in construction applications

by Catherine Howlett | March 1, 2013 12:31 pm

[1]

[1]by Jason Bakus

Silicone’s excellent aging characteristics, resistance to ultraviolet (UV) light and weathering, and long effective life span has made pre-cured sealants a popular material for construction-related applications.

Pre-cured sealants of silicone are produced by extruding elastomeric sealant material and allowing it to cure to a rubbery, flexible product in a controlled manufacturing environment. They are packaged in cured form—often in rolls—instead of typical liquid form packaging such as tubes or pails. The sealant is installed using a thin layer of adhesive on each side to attach to the substrate being sealed. The material is then pressed into the adhesive to ensure adequate contact between the pre-cured sealant and the adhesive, as well as between the adhesive and the substrate.

[2]

[2]With the outer edges adhered to the substrate, the middle of the pre-cured sealant material (which is not bonded) acts as the area for expansion and contraction. Pre-cured sealants are most commonly produced as flat extrusions with a thickness of approximately 2 mm (0.08 in.) and widths varying from 12.7 to 356 mm (0.5 to 14 in.). They are readily available in many standard sizes and colors and are also offered in custom hues and designs to fit various application requirements. These custom pre-cured sealants are available with different surface textures designed to match the appearance of exterior insulation and finish systems (EIFS), stucco, and other surfaces.

Pre-cured sealants can also be produced with one or more notches in the extrusion, allowing the material to bend uniformly in specific locations and seal complex configurations in applications—such as inside and outside corners, parapet caps, and window mullions. Figure 1 demonstrates the basic steps involved in installing pre-cured sealant, including the application of the adhesive, pressing the pre-cured sealant into place, and the completed installation.

The movement capability for silicone pre-cured sealants is commonly 200+ percent, meaning the pre-cured sealant can expand at least twice as much as the original joint size, which is significantly higher than other types of sealing products. The combination of high movement capability and thin material gives silicone pre-cured sealants the ability to easily handle multi-directional movement. Other advantages include a wide operational temperature range, and better resistance to color fading.

Commercial building envelope repair

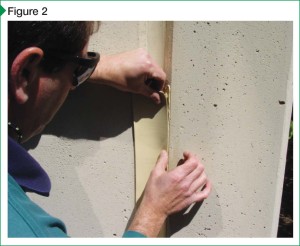

Pre-cured silicone sealants have been used in North America for the past two decades in the construction industry, mainly for commercial building envelope repair applications. An example of this application is the repair of failed, standard sealant joints. Figure 2 shows a 76.2-mm (3-in.) wide sandstone-colored pre-cured sealant being installed over an existing failed traditional sealant joint.

When pre-cured sealants are used to repair a failed traditional sealant joint, there is no need to remove the old sealant. Installation is straightforward; the pre-cured material is simply applied over the old joint using a thin layer of adhesive on each side of the material’s extrusion. One of the biggest advantages of using pre-cured sealants in these applications is they can be installed directly over the existing failed sealant and labor cost savings can be significant.

[3]

[3]The most common building envelope repair applications include:

- failed joint repair;

- EIFS joint repair;

- undersized expansion joints;

- roofing and parapet seals;

- flashing;

- splice joints;

- skylights;

- curtain wall seals;

- window perimeter seals; and

- window glazing.

Pre-cured sealants’ unique physical properties allow them to be used in applications where conventional sealants cannot perform. Among these applications are those in which the available joint configuration is not conducive to hourglass-shaped standard sealant joints, such as those with insufficient joint depth or width to handle the joint’s movement. This situation can often arise when joints are improperly designed, or when they are undersized due to faulty installations. The latter situation commonly occurs with window perimeter joints when the window opening is not accurately sized.

Other ideal applications for pre-cured sealants include joint repair in EIFS or other soft substrates that could be significantly damaged by removing the existing sealant. As the existing sealant material is not disturbed during installation, applications where the substrates or existing sealants contain hazardous materials—such as asbestos or polychlorinated biphenyls (PCBs)—can be properly addressed with pre-cured sealants.

[4]

[4]Metal buildings

While pre-cured silicone sealants have been used for many years in various building envelope restoration applications, they have recently been employed by some forward-thinking manufacturers and erectors in the metal building industry. There are many features of pre-cured sealants that make them ideal for various metal building-related applications. Their flexibility and high movement capability make them perfect for sealing areas experiencing a significant amount of thermal expansion and contraction—a situation commonly found in metal building and roofing applications.

The UV stability keeps pre-cured silicone sealants from degrading under the intense, long-term exposure to weather and the elements routinely found in these applications. One of the most important features of these sealants for metal building applications is no mechanical fasteners are required. The adhesive’s ‘green strength’ (i.e. the holding strength of the un-cured adhesive) secures the pre-cured sealants in place during cure. This enables them to be installed with no other means of attaching the material to the substrate, even on a vertical surface. Therefore, installation of pre-cured sealants is quick and efficient, particularly when compared to other materials commonly used in these and similar applications.

For example, all-metal or other ‘membrane’ sealants generally require many mechanical fasteners (up to 1500 per 30.5 m [100 ft] of material), often in addition to sealants and/or mastics. The large amount of fasteners dramatically increases the time and labor cost required for installation of these systems. Additionally, since every fastener creates another hole in the roof, the potential for leaks increases.

Pre-cured sealant systems are being successfully installed in many different applications within the metal buildings industry, including:

- expansion joints;

- roof-to-wall transitions (Figure 3);

- roof height change details;

- joints between new and existing buildings;

- roof gutter seams;

- ridge applications;

- roof penetrations;

- roof-curb seals; and

- miscellaneous repair applications.

Another important advantage of using pre-cured sealants in metal building applications is the adhesives typically bond strongly to metal substrates without use of a primer. When using neutral-cure silicone adhesive, such as oxime—or alcohol-based cure systems—as opposed to acetoxy or acid-cure adhesive systems, which give off a vinegar-like smell during cure—as recommended by manufacturers, the adhesive’s compatibility with metal building materials is not a concern.

Pre-cured sealants are commonly used in various metal building repair applications, often related to metal roofing. Some of these include the repair of holes in roof decking and of failed standing seams.

Storage bins

Another area of application for pre-cured sealants is large storage containers, such as grain storage bins. These require a watertight design to keep the contents dry and isolated from insects and other animals. Pre-cured sealants’ flexibility, along with their resistance to the weather and ability to adhere to various substrates, makes them suitable for use in applications relating to storage bin sealing. Pre-cured sealants can be used for:

- sealing between the storage bin and the concrete support slab;

- wall-to-roof joints;

- sealing around openings and penetrations; and

- gaskets for openings and bin access points.

Sealing the bottom of the storage bin typically requires a bond to both the steel wall of the bin and the concrete support slab. The ability of pre-cured sealant systems to bond to various types of substrates, including steel, concrete, and many others, is a significant advantage for these products in storage container applications.

[5]

[5]Residential applications

Many of the same attributes making pre-cured sealants an excellent choice for various commercial and industrial applications also allows them to perform effectively in residential applications. Pre-cured sealants can be used in sealing areas such as windows, skylights, roofing, HVAC, and many other household applications.

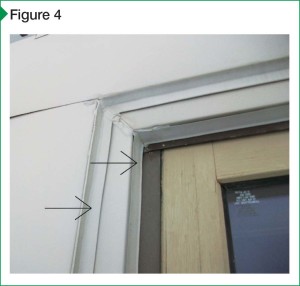

Figure 4 shows pre-cured sealants installed in a residential window application. In this particular application, the pre-cured sealant is installed in two different areas of the window system where the existing sealant and gasket material have failed, causing water leaks at these areas. Both of these installation areas are corners, which demonstrate the flexibility of pre-cured sealants, as well as their ability to be installed in various configurations. This application is an example of where notched pre-cured sealants can be bent into different shapes and installed in areas such as corners, window mullions, and other difficult-to-seal applications. As shown in Figure 4, pre-cured sealants can be color-matched, allowing them to blend in well with the substrate.

In addition to sealing leaks and keeping homes watertight, pre-cured sealants can also be very beneficial because of their capacity to stop air leaks. Sealing these leaks is a critical part of reducing heating and cooling losses and, thus, decreasing the overall energy use and costs associated with the home.

[6]

[6]Non-standard forms of pre-cured sealants

In addition to the previously discussed standard and notched materials, pre-cured sealants can also be extruded in various shapes to perform explicit functions. One specific example of a non-standard pre-cured sealant is a thicker, ribbed material cut into pieces, often called pads, and used as an accessory during production of insulating glass units (IGUs) in windows and doors.

Hot-melt butyl sealant is commonly incorporated into IGUs. Certain silicone pre-cured sealant formulations keep the hot-melt sealant from sticking to it, allowing the pre-cured sealant pad to be used as a tooling device with these sealants. Additionally, the thicker material helps insulate the user from the heat of the hot IGU sealant, making it safer to use than other materials for this application. Figure 5 shows a pre-cured sealant pad being used for tooling of hot-melt butyl IGU sealant.

Other examples of non-standard pre-cured sealants include:

- rectangular gaskets used for sealing doors and other openings;

- triangular or trapezoidal shapes for repairing failed glazing gaskets on windows; and

- thicker (up to 6 mm [1/4 in.]) material used for instances where more abrasion resistance is required.

Pre-cured sealants can be ‘green’

Pre-cured sealants can also help address a critical issue for construction—creating a greener building. Most structures, new and existing, have numerous leaks in the envelope, many of which are in the joint areas. Virtually any area in a building susceptible to leaks can be sealed using pre-cured sealants. Once these are sealed, the facility is more energy-efficient and a significant reduction of heating and cooling costs can be realized.

Improved energy efficiency and other factors, such as low volatile organic content (VOC) and insulating properties, allow pre-cured sealants to be an integral part of obtaining the U.S. Green Building Council’s (USGBC’s) Leadership in Energy and Environmental Design (LEED) certification for either new construction or existing buildings, particularly in the following areas:

- Energy and Atmosphere (EA) Pre-requisite 2, Minimum Energy Performance;

- EA Credit 1, Optimize Energy Performance;

- Indoor Environmental Quality (EQ) Credit 4.1, Low-emitting Materials: Adhesives and Sealants; and

- EQ Credit 7.1, Thermal Comfort: Design.

Additionally, the manufacturing efficiency and ability for production waste material to be recycled add to sealants’ sustainable characteristics.

Conclusion

In addition to the applications discussed, pre-cured sealants are also used in other areas such as marine, transportation, and industrial-related applications. They can be effectively employed in any application where flexibility, movement capability, ease of installation, and/or a water or airtight seal is needed.

As leaders in the construction industry continue to realize the impact cost savings, product performance, and efficiency pre-cured sealants can make in various applications, it is expected the market for the material will continue to grow. There are certainly many other applications for pre-cured sealants, including several that have not yet been discovered.

Jason Bakus is the vice president of Sealex Inc., a producer and developer of pre-cured sealants and adhesives. He has more than 15 years of experience in the pre-cured sealant and silicone technology markets and is the author of numerous technical articles on pre-cured sealants and their applications. Bakus can be reached via e-mail at jbakus@sealexinc.com.

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/Front-of-Building.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/sealants_Figure1.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/03/sealants_Figure2.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/03/sealants_Figure3.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/03/sealants_Figure4.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/03/sealants_Figure5.jpg

Source URL: https://www.constructionspecifier.com/using-pre-cured-sealants-in-construction-applications/