Photo © Phillip Parker

by Keith Boyer, PE

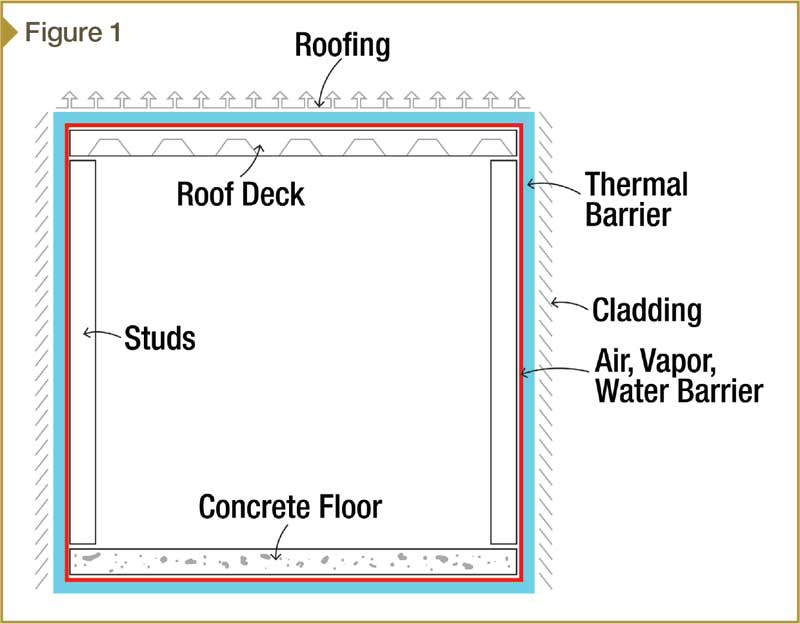

Building envelopes are typically a series of materials separating the building interior climate from the exterior. All these materials must be connected from wall to roof, and wall to floor/foundation; they need to encapsulate the building and perform specific functions in resisting moisture in liquid and vapor states, air infiltration, and heat flow.

These assemblies have been identified as “control layers” or “essential barriers”—either way, the interaction of the critical control layers can be complex. When not properly selected or installed, these systems can lead to issues related to entrapped moisture within the building envelope.

Insulated metal panels (IMPs) are a unique building material that include all these components in one unit that help to simplify the sometimes-complex arrangement of materials in building envelopes. Before exploring the benefits of single-source systems like IMPs, it is important to understand the roles of the building envelope in general.

The four barriers

The four essential barriers of the envelope—water, air, vapor, and thermal—have complex interactions (Figure 1). Some materials perform double duty; for example, a water barrier can also serve as the air barrier and possibly even the vapor barrier. If a vapor barrier is not desired as part of the air and water barrier, then a vapor-permeable air and water barrier may be used.

In most instances, the insulation will be a separate element. In many cases, the location of the vapor barrier relative to this insulation will be important; in others, the vapor barrier may not be desired or needed in the first place. To further add to the confusion, there are materials with permeance varying with the relative humidity (RH). Each barrier has its own characteristics and can contribute to specific performance challenges related to entrapped moisture.

Image courtesy Centria

Water barrier

The performance of the water barrier is based on ASTM E331, Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure Difference, which tests for watertightness under a set water load and pressure difference across the barrier. The International Building Code (IBC) mandates a minimum 300 Pa (6.24-psf) pressure difference. Pressure differences up to 718 Pa (15 psf) are common for building envelopes.

Water barriers must be continuous as most water leaks relate to breaks in that layer. While these defects are usually quickly identified and repaired, there are details that can accumulate rainwater within the wall cavity. This severely damages the building envelope in the long term if not corrected.

Air barrier

The performance of the air barrier system is based on ASTM E283, Standard Test Method for Determining Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure Differences Across the Specimen. It is tested for air leakage under a defined pressure difference. Air leakage of 0.3 L/s/m2 (0.03 cfm/sf) at a pressure of 75 Pa (1.57 psf), equivalent to 40 km/h (25 mph), is common. Additional pressures up to 300 Pa (6.24 psf), equivalent to 80 km/h (50 mph), are sometimes specified.

As with the water barrier, continuity is critical. A break in the air barrier is the second-most severe issue where air can flow through a wall in a circuitous path and create discomfort, especially in cold climates. Also, moisture flowing through the wall in the air in the form of vapor can condense on surfaces that would be below the dewpoint of the moving air, resulting in entrapped moisture within the wall cavity. Surprising volumes of water can be transported and deposited within the wall in this process, leading to material degradation and mold growth. Air barriers must also be designed to resist the positive and negative structural wind loads.