ACI 437 defines three acceptance criteria and their relative limits:

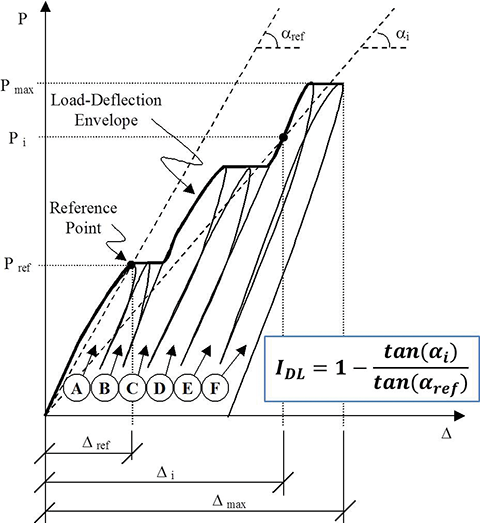

- The deviation from linearity index (IDL) criterion represents the measure of the nonlinear behavior of a member being tested at any time during the test. It is defined in Figure 4, and its limit is set at 25 percent.

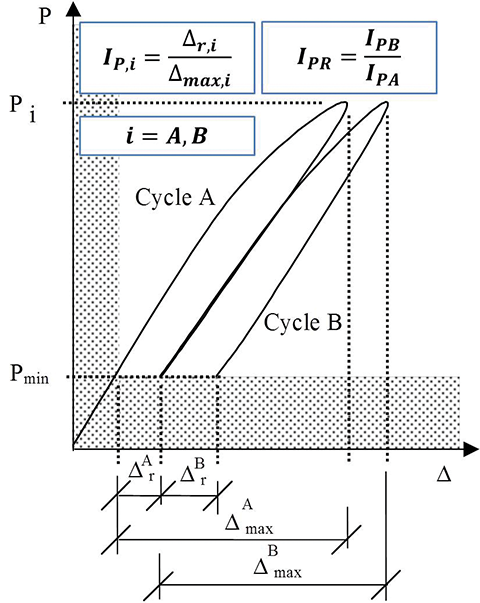

- The permanency index (IPR) criterion measures the ratio between the amounts of permanent change displayed by any structural response parameter during the first and the second of two identical load cycles (i.e. Cycles A and B, C and D, and/or E and F). It is defined in Figure 5, and its limit is set at 50 percent.

- The residual deflection criterion is the ratio between the residual deflection measured at least 24 hours after the removal of the load and the maximum deflection measured during the test. This ratio cannot be larger than 25 percent.

If one of the three acceptance criteria is not satisfied, ACI 437 allows repeating the test under the condition the maximum deflection measured during the test does not exceed 1/180 of the distance between the centers of the supports. The repeat test can be considered acceptable when the residual deflection recovery (measured at least 24 hours after the removal of the load) relative to the repeat test only is smaller than one-tenth of the maximum deflection measured during the repeat test only. Additionally, studies are currently under way to combine these parameters into one.

AISC manual

Appendix 5 of the AISC Steel Construction Manual (14th edition) provides guidance for evaluating existing steel structures (with focus on floors or roofs) by load testing for “verification of a specific set of design loadings,” or “determination of the available strength of a force resisting member of system.”

According to the manual, the test load magnitude can be calibrated to assess the structure’s strength or serviceability requirements. Also, when the strength requirements are investigated, the test load should equal the ultimate factored design load. The load should be applied incrementally, the test load held for at least one hour, and the structural response monitored at critical locations during the entire duration of the test.

The structure (or part being tested) is deemed to pass when the recorded deformations do not increase by more than 10 percent during the one-hour holding period of the test load. This document does not provide guidance on the allowable limits of permanent deformations. When the serviceability requirements are investigated, the test load magnitude should equal the service design loads, but no acceptable limits for the deformations under service conditions are provided.

Other codes

For buildings made of materials other than concrete and steel, development of the load test protocols and of the acceptance criteria is often left to the licensed design professional. For example, while mandating the load test procedure should simulate applicable loading and deformation conditions, the test load be applied for at least 24 hours, and the tested system be continuously monitored during the load test execution, IBC does not provide explicit guidance regarding the magnitude of the test load to be applied. On the other hand, some local building codes are more specific. New York City’s building code, for example, requires the test load be equal to two times the unfactored design loads.

To evaluate the response of the tested system, IBC provides two different sets of acceptance criteria. One set aims at verifying the tested system shows no evidence of failure during and after the test—in other words, excessive deflections or localized deformations obviously incompatible with safety requirements. The other set of acceptance criteria aims at verifying the measured maximum and residual deflections do not exceed the code-prescribed serviceable deflection limits and residual deformation, respectively.