No impact on guests

HEI Hotels & Resorts wanted to ensure the façade restoration project would have minimal impact on room reservations and guest activities. Typically, odors are a major concern and point of complaint for building occupants during this type of renovation. Since the coatings are water-borne and low in volatile organic compounds (VOCs) and odor, the project was completed with no impact on room reservations and hotel use by guests.

The water-based coating system is environmentally responsible as well. Not only is the VOC content very low, but also the long life cycle of the product creates a sustainable, low-carbon-footprint solution for the building because it eliminates the need to recoat the property every two to five years, thus reducing the amount of consumables used and the amount of consumable refuse going into landfills. With this system, property owners can expect 20 to 30 years of protection and reduced maintenance.

Project details

Coating contracting company Stuart Dean performed three-dimensional mockups of the structure to create the look designed by the architect for the project. The mockup process allowed the façade restoration experts at Stuart Dean to conduct adhesion testing and gave HEI an opportunity to verify the finish and color met expectations.

Prior to coating, all exterior surfaces were pressure cleaned using a minimum of 17,237 kPa (2500 psi) water to remove loose surface contamination, salt deposits, and mildew. On areas where mildew was present, it was removed using a bleach-based solution, and then the surface was rinsed with water. Metal surfaces (windows, doors, frames, and railings) were scraped and sanded to remove all loose paint and contaminants before being wiped with solvents prior to priming. Cracks in the brick, stucco, and masonry were repaired by removing loose or deteriorated material, grinding out the cracks, and thoroughly cleaning the surface and interior of the joints. Paintable caulk was then applied. Loose bricks were removed and the surface was cleaned to remove dust. Then, a bonding agent was applied to the surface and the brick face was reformed with stucco to match the surrounding areas.

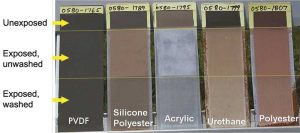

Using the PVDF-based formulation allowed the Stuart Dean crew to avoid hard-to-blend roller marks, one of the biggest challenges associated with rolling a coating onto a surface in high ambient temperatures. The masonry was sealed, followed by one coat of primer, and one coat of topcoat at 0.05 mm (2 mils) dry was applied to all surfaces.

“We were able to keep a nice wet edge, which can be difficult to do in the hot, humid Florida climate, because coated areas tend to dry too quickly,” said Rex Dean, global director, façade restoration, Stuart Dean. “Since the coating system was water-based, we also were faced with fewer restrictions for application such as dewpoint and relative humidity (RH), thus assisting an accelerated completion schedule.”

Fresh new look

Although the project was briefly interrupted for Hurricane Irma, the Stuart Dean crew finished the project quickly and efficiently, in about five months. The property now has a fresh, lighter, and brighter look.

Erin Brown-Neff is the director of marketing and business development for APV Engineered Coatings. She is responsible for generating new business accounts and managing key product development projects in strategic markets including architecture and building products. She also oversees external communications, public relations, and advertising, as well as website and digital marketing efforts. Brown-Neff has a bachelor’s degree in business and marketing management from the University of Akron. She is a National Association of Corrosion Engineers- (NACE) certified coating inspector. Brown-Neff can be reached at ebrown@apvcoatings.com.