What non-engineers need to know about structural masonry

by Katie Daniel | April 6, 2018 10:07 am

[1]

[1]by Pat Conway, CSI, AIA, Sam Rubenzer, PE, SE, and David Sovinski

Structural masonry saves time and money while providing a durable solution for building design. Masonry has outstanding load carrying and transfer capabilities but is too often relegated to veneer, infill, or over-designed structural elements. This creates an inefficient construction delivery system and misuse of material, which can negatively impact cost, schedule, and space. All parties in the design and construction process benefit from understanding the basic and advanced principles of structural masonry and how they are applied.

This article discusses uses of masonry systems, from total building solutions and hybrid solutions with steel or concrete frames to partial solutions such as stairs, shafts, fire walls, and foundations. Other considerations include relative costs, scheduling implications, important detailing, and performance issues, as well as the use of simple software packages to create the most effective structural system.

Useful resources for non-engineers

Codes, standards, software, and industry support are readily available to help engineers and non-engineers alike make effective use of structural masonry.

Codes and standards

The Masonry Society (TMS) 402/602, Building Code Requirements and Specification for Masonry Structures, includes both mandatory and optional checklists, which offer guidance for specifiers and help ensure project specifications meet code. The mandatory list includes required specifications, like the minimum compressive strength of the masonry for a specific project. The optional list includes considerations like the use of joint reinforcement as shear reinforcement.

ASTM standards are another resource. ASTM C90, Standard Specification for Loadbearing Concrete Masonry Units, is commonly used for projects requiring loadbearing concrete masonry. It sets minimum requirements for the units. In some cases, a designer may specify requirements above the minimums, which can often be done with minor impact on the unit cost. If specifications do not reference the version of the standard, by default, the version referenced by local building codes will be used.

Though ASTM C90 sets the minimum compressive strength requirement for the units, it does not set a maximum. Often, it is advisable to specify a higher unit strength, which can result in a higher compressive strength for the masonry wall itself.

Manufacturers and distributors

One can check with local concrete masonry manufacturers and distributors for locally available unit strength and options for high-strength units.

Structural masonry coalitions

There are more than a dozen regional structural masonry coalitions around the country offering free engineering support, as well as providing education, software, training, and conceptual design. The coalitions have proven to produce lower cost designs, and in some cases, thinner masonry wall systems resulting in delivery efficiencies. (To inquire about coalition availability in one’s area and for more information, contact the International Masonry Institute [IMI] at 1.800.IMI.0988 or at imiweb.org/4-contact[2].)

Typical floor plans and layouts

Whole building solutions are what most construction professionals think of when they hear about structural or loadbearing masonry. The common perception is loadbearing, whole building solutions are best suited for mid- and low-rise structures. While masonry is a great solution in these applications, high-rise construction can benefit from partial solutions like infill, shear walls, stairs, and shafts.

Masonry structural solutions also bring the added benefits of security and safety from fire, wind, blast, and impact, as well as natural thermal and sound control. Certain layouts and floor plans work very well with structural masonry whole building solutions. The following floor plans are typical for a hotel, dormitory, multifamily housing, senior living, health care, school, and other structures.

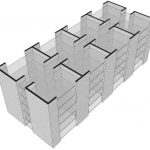

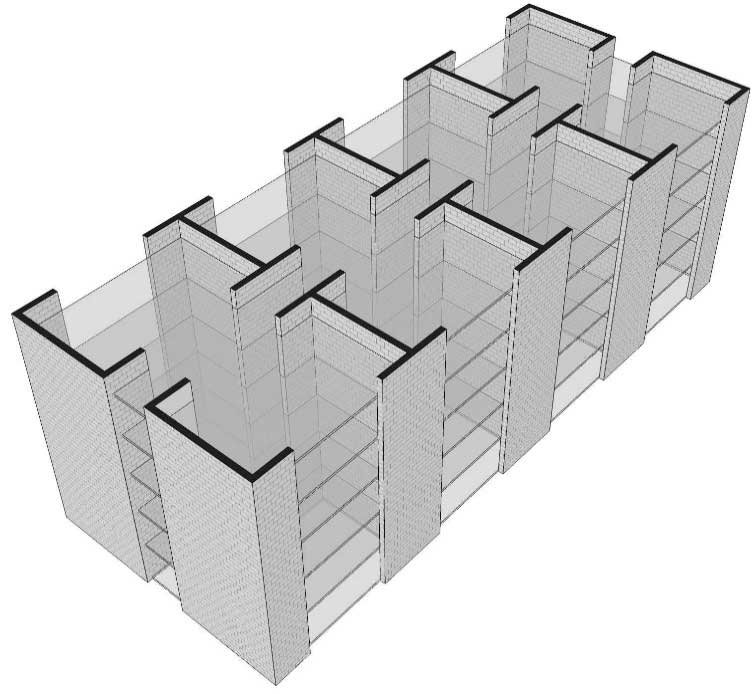

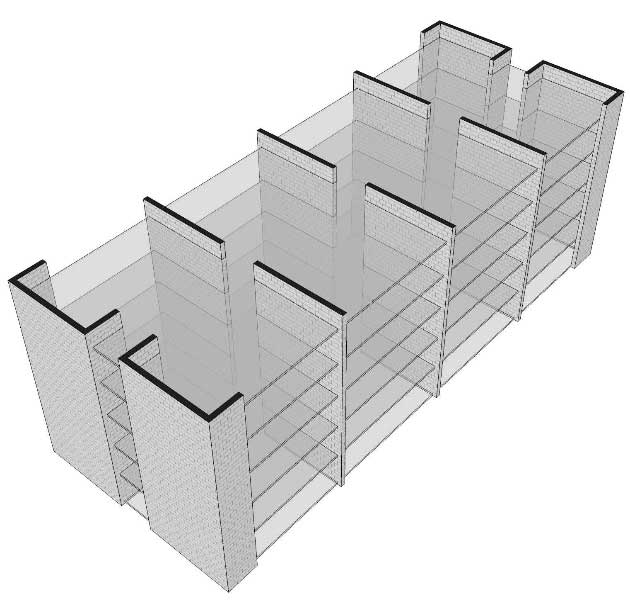

- A simple cross-bearing wall layout is structurally efficient with its symmetrical layout and myriad shear wall options (Figure 1).

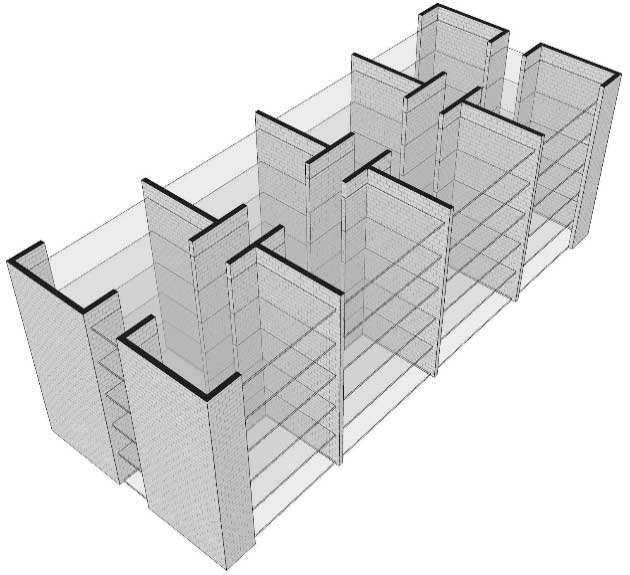

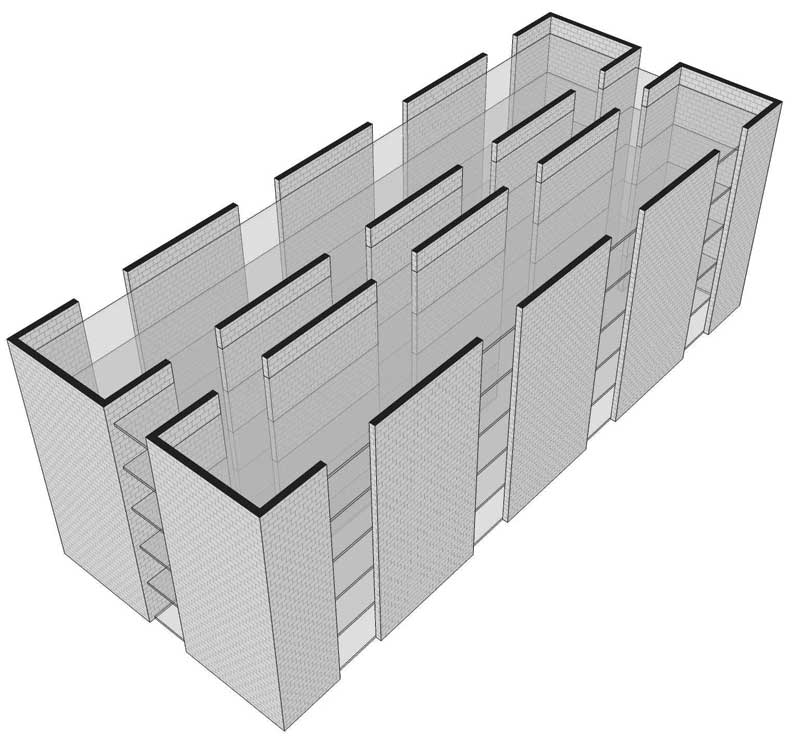

- The cross-bearing wall layout depicted in Figure 2 provides more flexibility with the exterior walls, as many are not employed as bearing or shear walls. From the engineer’s perspective, it could be more challenging to distribute the shear loads in Figure 2 than in Figure 1. The corridor walls are still used as shear walls in this option.

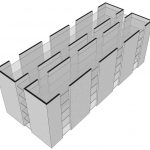

- Figure 3 takes it a step further. The layout frees up the corridor walls and uses end walls only for shear. It offers great architectural flexibility, but can be limiting from a structural standpoint.

- Not all layouts have to be variations of a cross-bearing wall plan. Figure 4 is an example of a longitudinal bearing wall plan. Typically, these layouts are employed for shorter buildings and may need added shear walls in taller structures or higher seismic areas.

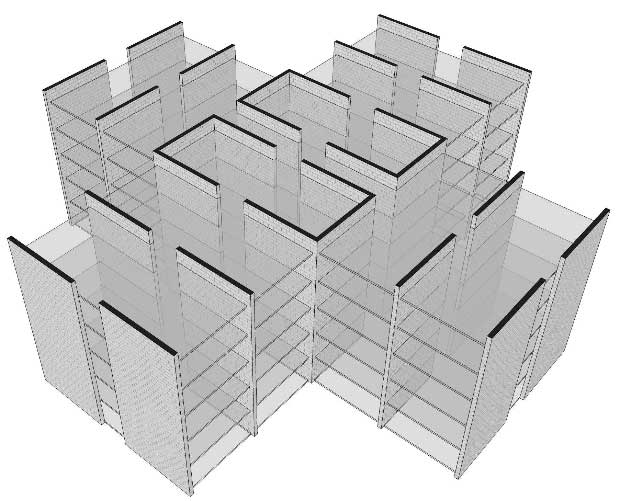

- Structural layouts do not have to be rectangles; combining options produces T, X, H, I, and L-shaped structures, just to name a few. Masonry also works well for curves. Figure 5 shows a central core option with elevators and stairwells, which serve well as shear and loadbearing walls.

When is structural masonry the right solution?

One must keep the benefits of structural masonry in mind when searching for the right solution to a building need. As a system, structural masonry provides:

- fire safety;

- sound control;

- impact-, blast-, and wind-resistance;

- thermal mass benefits;

- a single-source building trade solution;

- fast delivery;

- simple jobsite modifications; and

- the ability to act as both structure and finish.

Structural masonry is wall bearing, not a beam and column system like structural steel frames. In many situations, this gives the advantage of lighter foundations, which can be designed and laid faster. It also offers continuous anchorage and construction sequencing benefits, like starting in multiple locations.

[7]

[7]Hybrid systems

If a building configuration or other design criteria call for a steel frame, consider a hybrid solution. Some hybrid systems combine a steel frame with concrete masonry. In this type of system, the masonry and steel are engineered to provide load-sharing between the steel frame and the masonry infill. This eliminates some of the complicated steel bracing configurations and moment connections, allowing for a downsized steel frame and saving cost. Often the choice for infill in a frame is concrete masonry. If it is already on the project, it only makes sense

to use it in a structural capacity to save time and create efficiencies.

Stairs and shafts

Masonry shaft walls for stairs or elevators have many positive attributes from both an engineering and architectural perspective. Architectural masonry shafts offer economical fire resistance, mass for thermal and acoustic benefits, and a familiar, durable, finished surface.

From a structural perspective, concrete masonry shaft walls can provide sufficient lateral support for the entire structure. Boxed wall groups have more stiffness and strength than individual walls of the same length and thickness. These wall groups are sufficient for buildings of all material types and framing systems.

Storm shelters

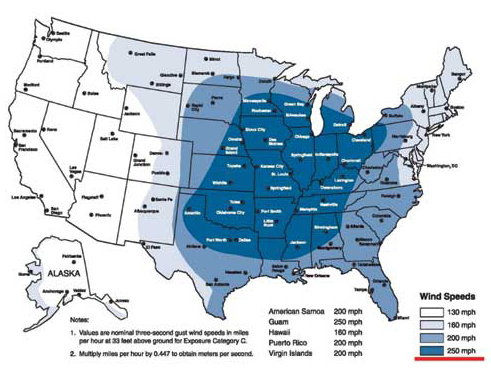

Reinforced concrete masonry is an excellent solution for situations requiring protection from blast, impact, or high wind, particularly storm or tornado shelters. The 2015 International Building Code (IBC) has adopted the 2014 International Code Council (ICC) 500, Standard for the Design and Construction of Storm Shelters. The ICC 500 mandates storm shelters for certain geographic areas and certain building uses, including critical facilities (e.g. 911 stations, emergency operation centers, and fire, rescue, ambulance, and police stations), and Group E occupancies, or schools having an aggregate occupant load of 50 or more (with a few exceptions).

Once 2015 IBC is implemented, the new requirement will impact the majority of new school construction, from Minnesota to southern Mississippi, western Pennsylvania and Texas, and all the areas in between (Figure 6).

Reinforced masonry offers multiple options for compliance with these mandated requirements—from single-wythe reinforced and solidly grouted concrete masonry to reinforced and solidly grouted brick masonry, as well as partially grouted masonry cavity wall systems. The growth of masonry industry certifications, design support, and improved connection details makes masonry an excellent choice for all high-wind sheltering.

[8]

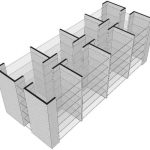

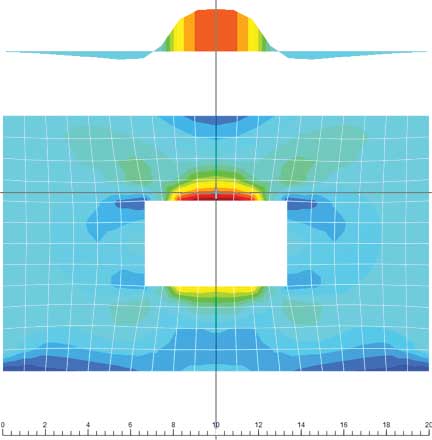

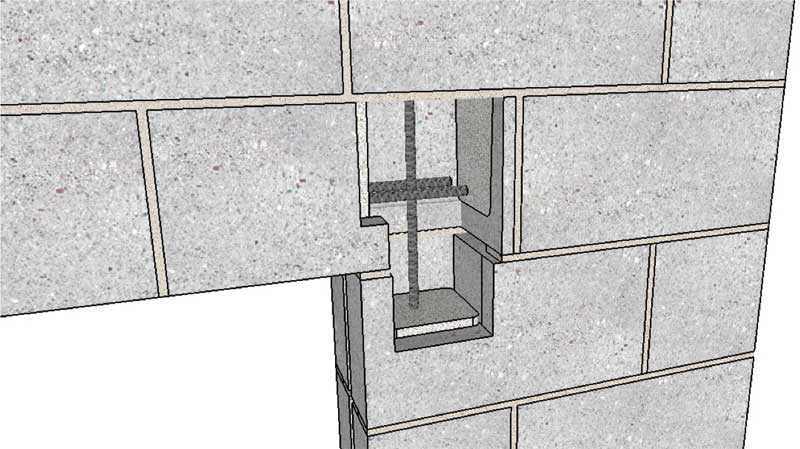

[8]Lintels

Masonry lintels can be critical to efficient masonry design. If control joints are properly located away from the opening edge, the lintels can be designed as a connecting element between the walls on each side of the opening. If masonry lintels are analyzed and designed in a sophisticated software program using finite element analysis, it is easy to understand the design forces for the lintel element. With such software, it is not necessary to create a separate entity for a masonry lintel. Instead, the lintel is part of the wall most accurately representing the real wall structure. The masonry lintel creates an integral joint with vertical jamb reinforcement. This leads to a more robust design than other lintel solutions that would be separate from the wall.

In finite element analysis (FEA), because of the integral nature of the lintel with the plate elements representing the wall around the lintel and opening, the forces generated will be similar to a fixed-end beam. This is a more efficient way to design the lintel itself, and creates a more robust and efficient overall wall design.

[9]

[9]Photo © Pat Conway

Cost, speed, and quality control

In all the situations above, efficiently designed structural masonry can reduce cost and increase both quality and speed of construction. Concrete masonry is sourced locally, with fabrication plants across the United States carrying enough stock or having the production capacity to give near-immediate product delivery. Using local materials creates local jobs in masonry production, transportation, and installation.

Structural masonry building systems do not require fabrication shop drawings, which decreases the time between concept and implementation. The modular sizing and nature of the product also allows for easy field changes in order to accommodate design issues or tolerances of nearby materials.

A recently constructed elementary school gymnasium in Wisconsin went from ground to finish in just four days, illustrating the cost, speed, and quality benefits of masonry. Bringing the “four-day gym” to life only took 12 masons, six laborers, two tenders, and six pieces of hydro-mobile scaffolding. The construction team pushing for a solution similar to this four-day gym routinely value-engineers masonry into their structures, improving the bottom line, reducing the risk of moisture-related call-backs, and shortening construction times. The contractor or construction manager on the project often works with the region’s structural masonry coalition to create more efficient use of reinforcement, grout, and unit size. In particular, masonry lintels may be proposed, which can be faster, less costly, and more robust than steel wide flange lintels with thin masonry face shells precariously connected to it.

Tips for structural masonry construction

Here are more practical tips for optimizing structural masonry construction.

Make effective use of joint reinforcement

Joint reinforcement can be used to meet horizontal reinforcement requirements in many cases. Bond beams are typically a more expensive option, but can offer more horizontal steel reinforcement area. Both can and should be used for different needs.

Specify higher unit strength

Consider specifying concrete masonry units (CMUs) with unit compressive strengths above ASTM’s minimum requirements. The higher unit strength results in higher masonry assembly compressive strength (f’m). This can create cost-savings, since it reduces the need for vertical reinforcement and grout. Partially grouted walls can also be structural.

Be mindful of grouting methods

One option may be to let the masonry contractor choose the method of installing the grout, low or high lift. However, it is important to understand the difference between a grout pour and a grout lift because codes have evolved to consistently allow higher grout pours and lifts.

One must make sure to specify grout strength properly. The minimum permissible compressive strength for grout is 13,790 kPa (2000 psi) at 28 days. For many projects, this may be appropriate. However, code requires grout compressive strength equal or exceed f’m. When f’m is specified as greater than 2000 psi, then the grout compressive strength should be specified to either equal or exceed the specified f’m value. For example, if f’m is specified to be 2500 psi, the minimum specified grout strength, f’g, would be 2500 psi.

[10]

[10]Consider internal bracing

There are two approaches to bracing masonry walls under construction—external (traditional) and internal (well-established but not as often used). Both are engineered approaches. Using vertical rebar already existing in a wall provides resistance to lateral loads during construction. If the wall is engineered properly, this can reduce or eliminate the need for external bracing. (For more information, read the article, “Internal Bracing Design Guide for Masonry Walls Under Construction,” published by IMI at imiweb.org/wp-content/uploads/2015/11/IMIInternalBracingGuide.pdf[11].)

Modular design

One must be mindful of the modular quality of concrete masonry. By laying out a structure to minimize cut blocks, labor and material may be saved. Where concrete masonry is exposed in the final structure, taking the block module into account optimizes the appearance of exposed block.

Conclusion

Structural masonry is a proven system employing cutting edge design tools to create cost-effective, modern structures at a competitive cost and on an efficient schedule. With an improved understanding of structural masonry systems, design and construction professionals can more effectively optimize building delivery and performance. (Special thanks to Diane Throop, PE, FASTM, FTMS, for her edits and review of this article.)

Pat Conway, CSI, AIA, is the International Masonry Institute’s (IMI’s) director of education. He is a registered architect, with expertise in masonry rainscreen walls, air barriers, movement joints, flashing, jobsite troubleshooting, and contemporary masonry wall detailing. Conway has a degree in architecture from the University of Minnesota, and is an active member of both CSI and the American Institute of Architects (AIA). He can be reached at pconway@imiweb.org[12].

Sam Rubenzer, PE, SE, is the founder of FORSE, a structural engineering design and consulting firm working with structural masonry coalitions in several states. With more than 18 years of industry experience, Rubenzer assists engineers with the designs on a variety of projects, building types, and software programs. Rubenzer has a bachelor’s in civil engineering from Marquette University and also a master’s in business administration from the University of Minnesota. Rubenzer can be reached via email at sam@forseconsulting.com[13].

David Sovinski is IMI’s national director of industry development. His experience includes masonry project manager, estimator, and architecture and technology teacher at Indiana University Purdue University Indianapolis (IUPUI). Sovinski has a degree in construction management from Purdue University. He can be contacted at dsovinski@imiweb.org[14].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/04/eau-claire-office-building.jpg

- imiweb.org/4-contact: http://imiweb.org/4-contact

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/04/Figure-2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/04/Figure-3.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/04/Figure-4.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/04/Figure-5.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/04/lintel-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/04/Figure-6.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/04/lintels-lifted-in-place-madison-office-building.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/04/Lintel.jpg

- imiweb.org/wp-content/uploads/2015/11/IMIInternalBracingGuide.pdf: http://imiweb.org/wp-content/uploads/2015/11/IMIInternalBracingGuide.pdf

- pconway@imiweb.org: mailto:pconway@imiweb.org

- sam@forseconsulting.com: mailto:sam@forseconsulting.com

- dsovinski@imiweb.org: mailto:dsovinski@imiweb.org

Source URL: https://www.constructionspecifier.com/what-non-engineers-need-to-know-about-structural-masonry/

[3]

[3] [4]

[4] [5]

[5] [6]

[6]