When to use resilient channel

Office buildings

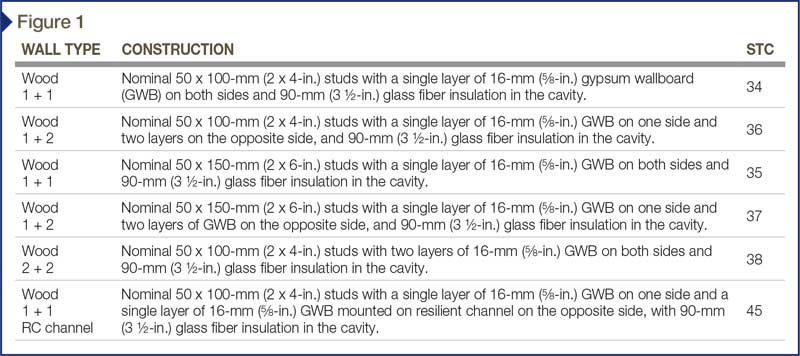

For an executive or private office space, the interior environment should be controlled to achieve 35 dBA on an hourly average. The space should also provide conversation privacy so those in adjacent and open offices, or in conference rooms, cannot overhear conversation. The Unified Facilities Criteria (UFC) implemented by the Department of Defense (DOD) establishes a minimum rating of STC 40 between private offices and STC 45 between conference and meeting rooms. Doors and windows installed within these sound-rated partitions should achieve, at minimum, STC 35. Figure 1 presents STC ratings for a variety of wall types. So, in constructing an STC 45 wall, is it more efficient to use layers of gypsum wallboard or to use resilient channel?

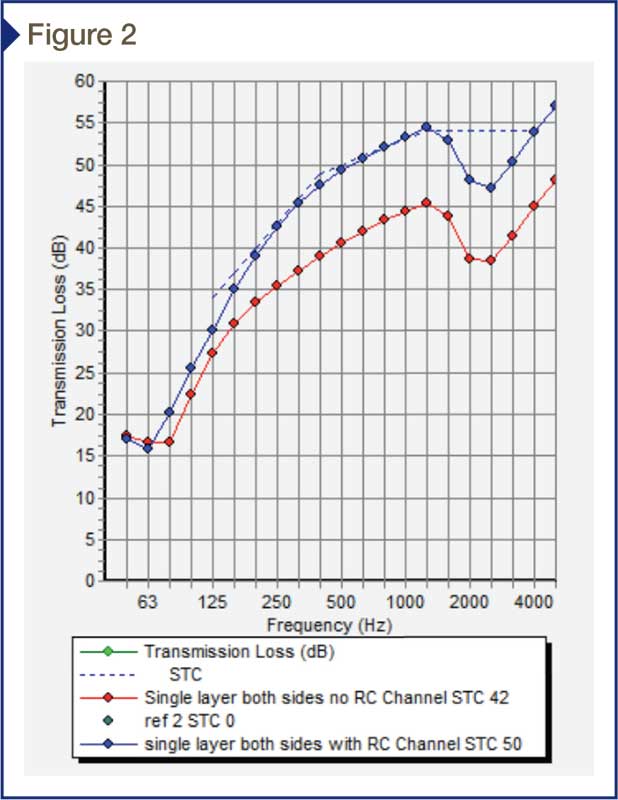

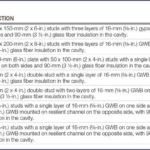

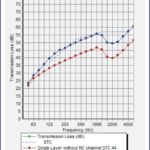

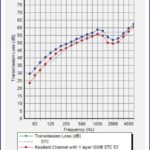

Resilient channel works by limiting the amount of vibration transmitted from one side of the wall to the other, where it is translated into sound using wallboard. Figure 2 illustrates the improvement that can be achieved by incorporating resilient channel in a standard 50 x 100-mm (2 x 4-in.) stud wall with a single layer of 16-mm (5⁄8-in.) gypsum wallboard on both sides and 90-mm (3 1⁄2-in.) batt insulation in the cavity.

The graph shows how well each method blocks sound at different frequencies by Hertz (Hz), from low to high. On the vertical column is transmission loss in decibels (dB). According to the table, at 1600 Hz, resilient channel will be able to reduce sound transmission by almost 10 dB more than wall without channel. Reducing a sound by 10 dB makes it appear to be half as loud to the human ear—a significant performance difference.

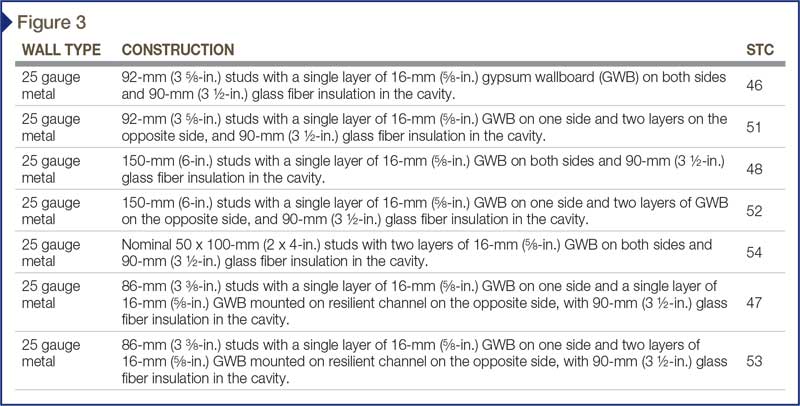

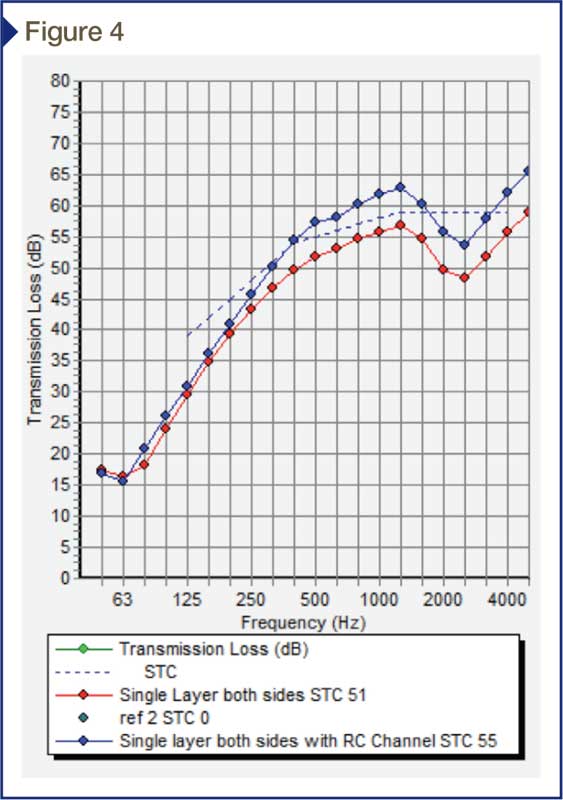

Figure 3 uses the same example and same goal (i.e. STC 45) for metal stud walls in private and executive offices, but achieves different results.

Figure 4 compares a 92-mm (3 5⁄8-in.) metal stud wall with resilient channel to one without. Light-gauge metal stud construction absorbs much of the vibration energy of a sound wave; thus, under these circumstances, high transmission loss performance can be achieved without resilient channel. Here, the product enhances performance only a fraction as much as it did with the standard wood stud wall. For metal framing and resilient channel, performance is improved to 5 dB at 1600 Hz, compared to almost 10 dB for the similar wood-framed construction.

Classroom and ancillary learning space walls

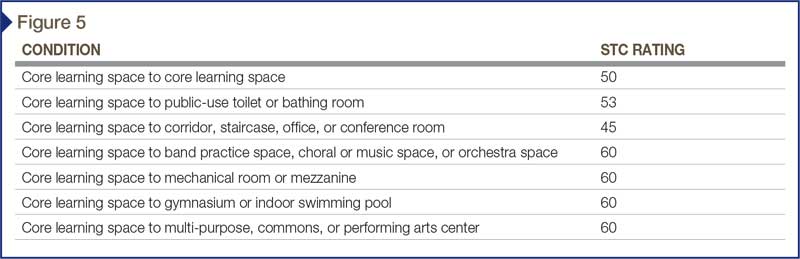

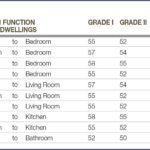

American National Standards Institute (ANSI) 12.60, Acoustical Performance Criteria, Design Requirements, and Guidelines for Schools, provides basic performance criteria for use within classrooms and other learning spaces. For core learning spaces (those where the primary functions are teaching and learning), background noise levels should be limited to an hourly average of 35 dB—if the space is smaller than 566 m3 (20,000 cf). For larger spaces, an hourly average of 40 dBA is recommended. These criteria, correlated with typical source noise levels within schools, can be used to develop STC wall performance standards between spaces. Columns one and two of Figure 5 list relevant school spaces and their required STC ratings.

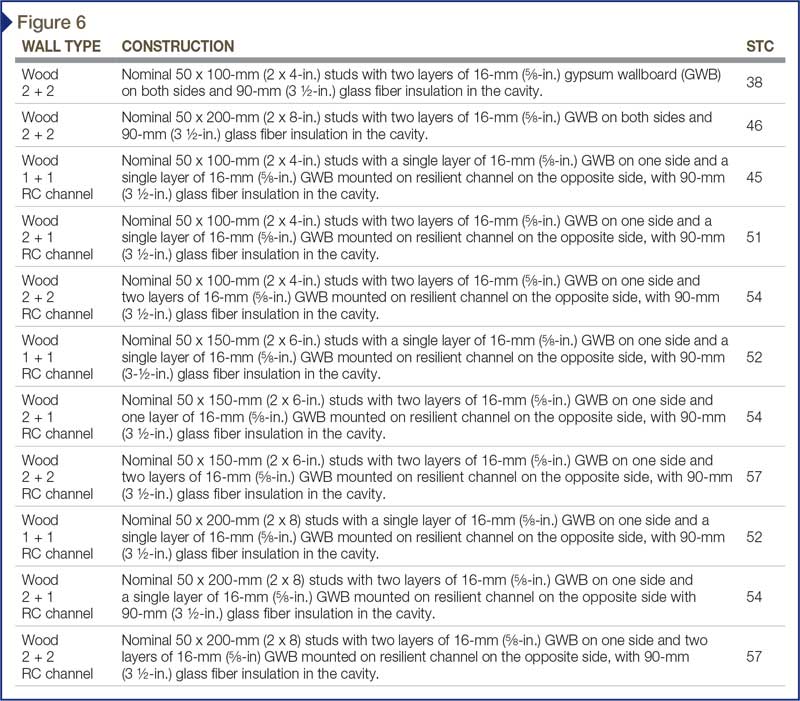

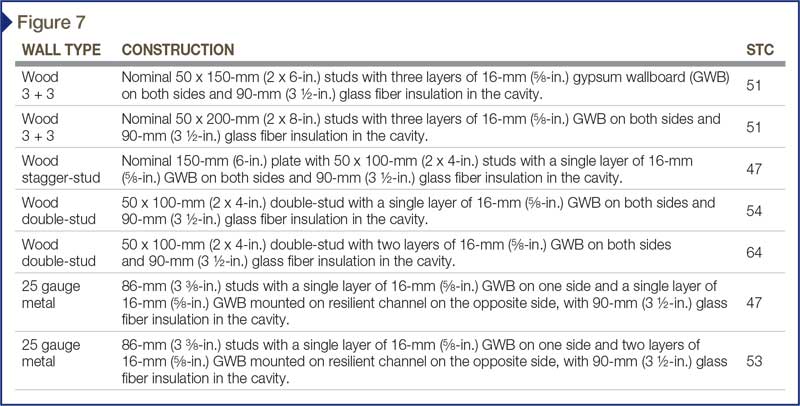

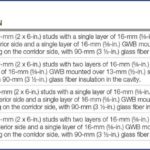

Achieving these results—especially in wood-frame construction—can be challenging without the use of resilient channel. Figure 6 and Figure 7 present a selection of assemblies and their predicted STC ratings, with and without resilient channel. For additional comparison, use of triple layers, as well as stagger-stud and double-stud construction, is also examined.

If resilient channel is not used to separate noise sources from core learning areas, the appropriate STC rating can be achieved by using more mass layers in the walls, or by creating thicker walls that provide a similar vibration break. A double-stud wall system with layers of wallboard can be used to achieve an STC above 60, but the wall thickness will need to be at least 317 mm (12 ½ in.) to do so.

Demising walls and corridor walls in residential construction

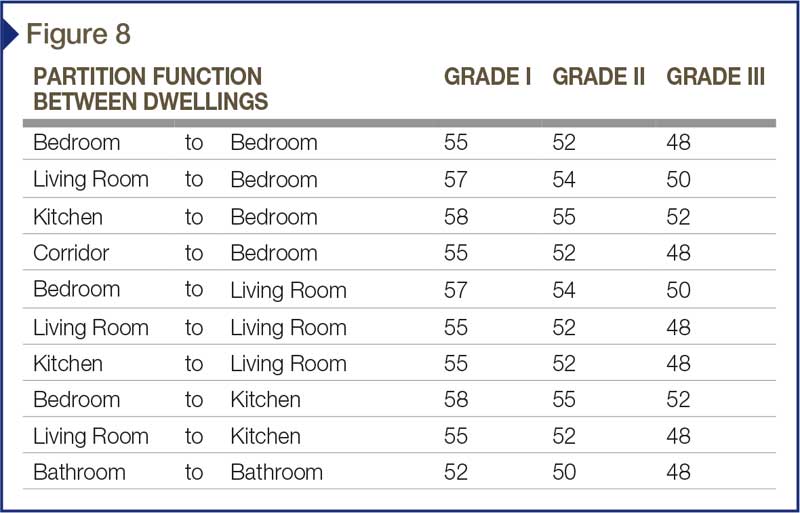

Under the standards established by the International Building Code (IBC), unit demising walls, floor/ceiling assemblies, and corridor walls should achieve an STC 50. These are minimum performance values—for most urban multi-family dwellings, a higher standard of performance is desired.

To attain the necessary STC, one must examine walls, floors, doors, windows, and mechanical and plumbing systems. Figure 8 (page 38) presents guidelines for airborne sound insulation for floor-ceiling assemblies and party wall construction. For reference, a Grade I standard requires an interior environment of 32 dBA, while the Grade II requires 37 dBA and Grade III needs 42 dBA.

It should be noted these performance levels are guidelines only and must be measured in the field. IBC standards provide a five-point allowance for a field measurement to document a laboratory-tested wall assembly.

When evaluating the condition of a demising wall between a living room and a bedroom (which requires a Grade I STC 57, Grade II STC 54, and Grade III STC 50, with an additional three-point allowance when field-constructed), it is possible to compare the wood-framed assemblies provided in Figures 6 and 7.

For demising walls with double-stud construction, structural shear layers are typically required and placed between studs. This can lower the STC performance of the assembly by eight to 10 points, due to the reduced size of the air cavity between wallboard layers. Stagger-stud construction, on the other hand, creates issues for waste, drain, and supply lines due to limited space within the wall cavity.

In a single-stud construction where structural shear walls are needed, it is possible to remove a layer of wallboard on the non-resilient channel side of the wall. However, this can only be done when the structural plywood is installed with the same level of penetration isolation given to a layer of drywall in an acoustical partition.

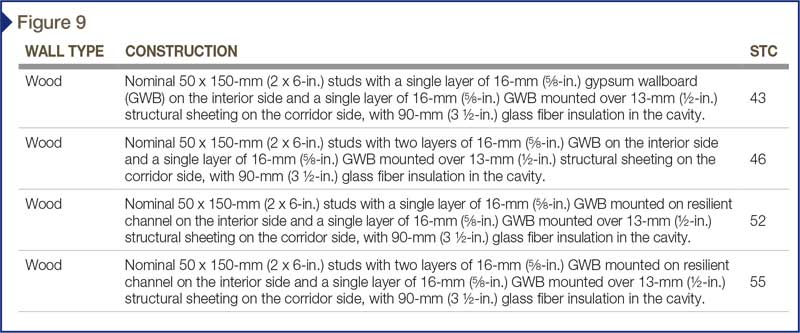

For corridor walls achieving STC 50 and higher (typically including shear wall layers and plumbing), framed wall system selection can often be resolved by using a 150-mm (6-in.) stud wall. However, expecting to achieve a field rating above STC 50 under these circumstances is impractical without the use of resilient channel. Figure 9 illustrates some potential results.

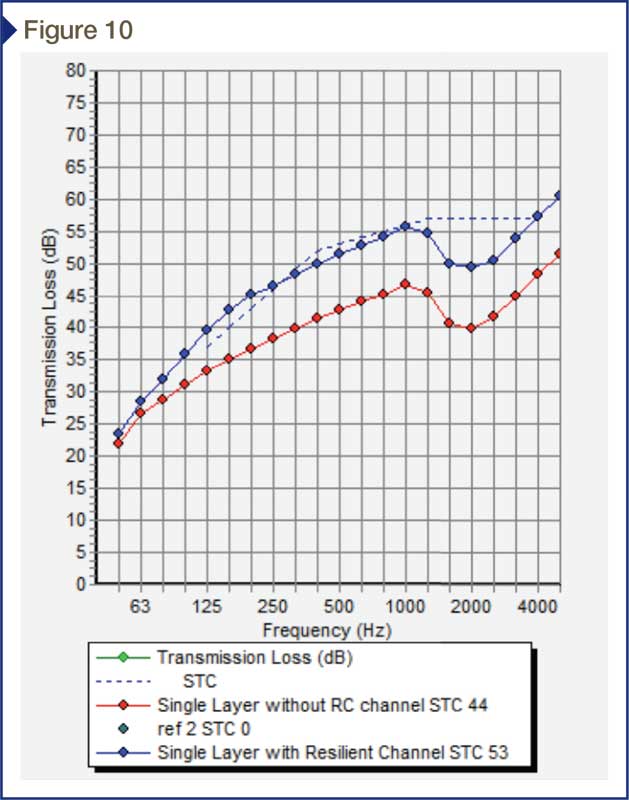

In floor/ceiling wood-framed residential construction, the application of the resilient channel becomes even more critical. A typical floor/ceiling assembly using solid lumber or I-joists falls far short of achieving the requirements of IBC. The Underwriters Laboratories (UL) L569 assembly, with 20-mm (¾-in.) gypsum topping, 20-mm plywood sub-floor, 250-mm (10-in.) solid wood joists, and a single layer of 16-mm (5⁄8-in.) gypsum wallboard, as well as 90-mm (3 ½-in.) batt insulation, achieves an STC 44. Adding resilient channel between the joists and gypsum wallboard can improve performance to STC 53, as demonstrated in Figure 10.

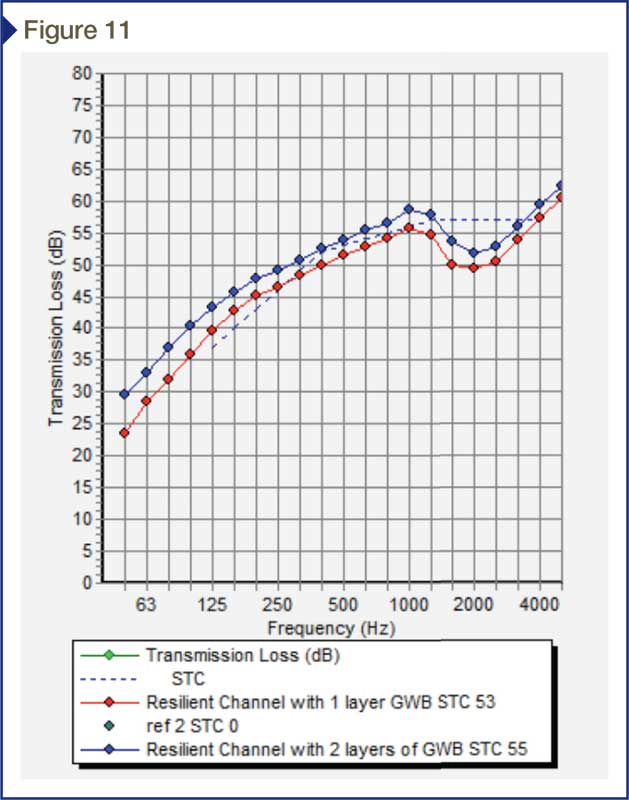

Figure 11 illustrates the improvement in transmission loss caused by adding a second layer of gypsum wallboard. This way, the STC 53 performance achieved with resilient channel and one layer of gypsum wallboard is improved to STC 55—a luxury standard in the stacked conditions of multi-family residential living.