When to use resilient channel

by Katie Daniel | January 3, 2017 11:03 am

by Bill Stewart

Resilient channel has been on the market for more than 50 years, but it seems not everyone has a clear idea of when it can be used to solve sound transmission issues in wall and floor/ceiling assemblies. As a consultant who has worked in engineering acoustics for more than 20 years, the most common question this author receives regarding resilient channel is: ‘Can I just replace it with a layer of gypsum wallboard?’

It is crucial to identify which conditions warrant the use of resilient channel. If, for example, adding a layer of gypsum wallboard to the assembly would indeed accomplish the same task with equal success, the situation is not one where it is practical to use this product.

Building professionals’ understanding of which conditions are appropriate for use of resilient channel can be enhanced by a review of the improvements achievable with its implementation. It is also essential to identify wall types commonly used for residential, education, and commercial construction, and to determine whether the product should be used with each type.

This article provides a review of the improvements that can be achieved by using resilient channel, as well as identifying wall types in common construction practice for residential, education, and commercial applications and determining whether resilient channel should be used.

The process of selecting a wall type is not as direct as it seems. Once design criteria are established for a structure’s desired interior noise level (typically an hourly average of the A-weighted equivalent sound level in dBA), the wall’s transmission loss performance must be determined. That performance should be high enough to reduce source noise levels until they meet the interior noise goal. Sound transmission class (STC) has been established by ASTM standards as the measure to use when gauging transmission loss performance.

For each space in the built environment, the source of noise and the acceptable level of sound must be understood before an ideal STC rating can be determined. In acoustics, this is referred to as the source-path-receive model.

Office buildings

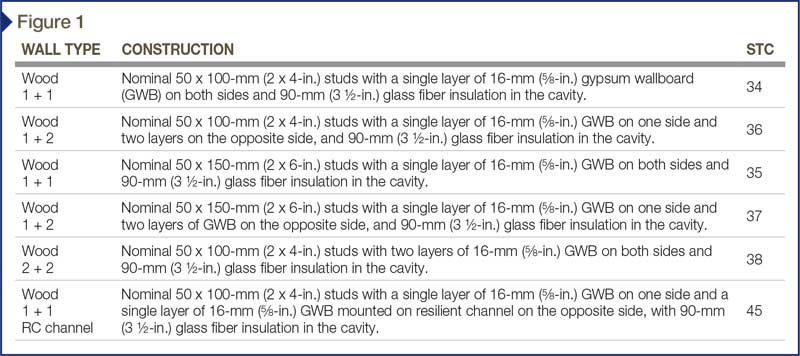

For an executive or private office space, the interior environment should be controlled to achieve 35 dBA on an hourly average. The space should also provide conversation privacy so those in adjacent and open offices, or in conference rooms, cannot overhear conversation. The Unified Facilities Criteria (UFC) implemented by the Department of Defense (DOD) establishes a minimum rating of STC 40 between private offices and STC 45 between conference and meeting rooms. Doors and windows installed within these sound-rated partitions should achieve, at minimum, STC 35. Figure 1 presents STC ratings for a variety of wall types. So, in constructing an STC 45 wall, is it more efficient to use layers of gypsum wallboard or to use resilient channel?

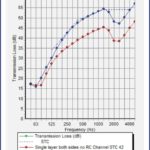

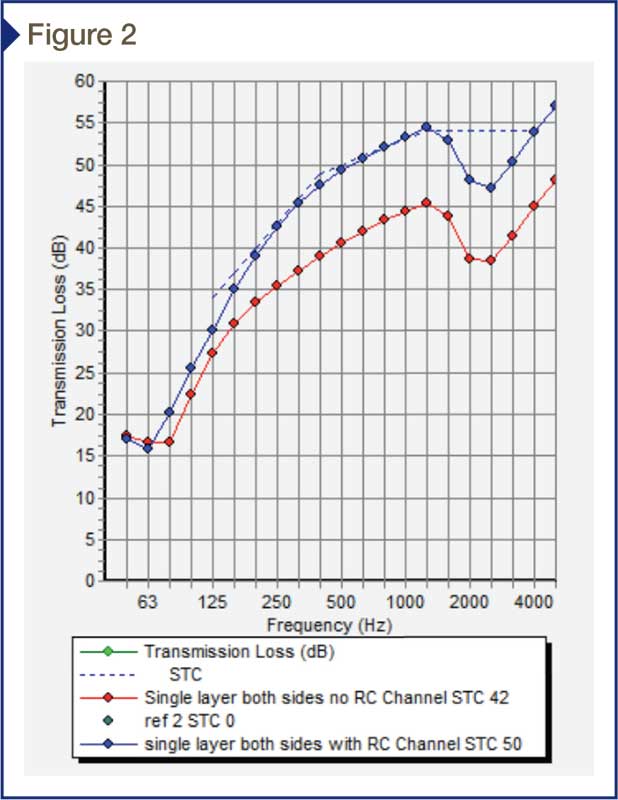

Resilient channel works by limiting the amount of vibration transmitted from one side of the wall to the other, where it is translated into sound using wallboard. Figure 2 illustrates the improvement that can be achieved by incorporating resilient channel in a standard 50 x 100-mm (2 x 4-in.) stud wall with a single layer of 16-mm (5⁄8-in.) gypsum wallboard on both sides and 90-mm (3 1⁄2-in.) batt insulation in the cavity.

The graph shows how well each method blocks sound at different frequencies by Hertz (Hz), from low to high. On the vertical column is transmission loss in decibels (dB). According to the table, at 1600 Hz, resilient channel will be able to reduce sound transmission by almost 10 dB more than wall without channel. Reducing a sound by 10 dB makes it appear to be half as loud to the human ear—a significant performance difference.

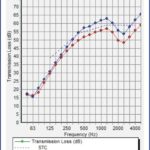

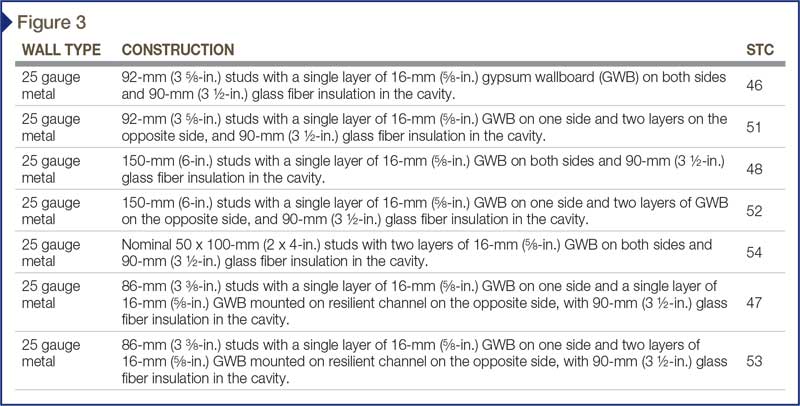

Figure 3 uses the same example and same goal (i.e. STC 45) for metal stud walls in private and executive offices, but achieves different results.

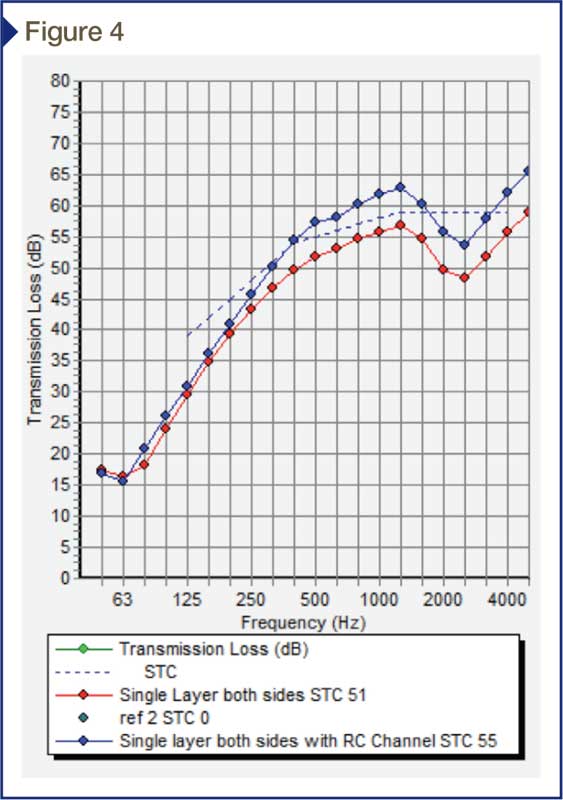

Figure 4 compares a 92-mm (3 5⁄8-in.) metal stud wall with resilient channel to one without. Light-gauge metal stud construction absorbs much of the vibration energy of a sound wave; thus, under these circumstances, high transmission loss performance can be achieved without resilient channel. Here, the product enhances performance only a fraction as much as it did with the standard wood stud wall. For metal framing and resilient channel, performance is improved to 5 dB at 1600 Hz, compared to almost 10 dB for the similar wood-framed construction.

Classroom and ancillary learning space walls

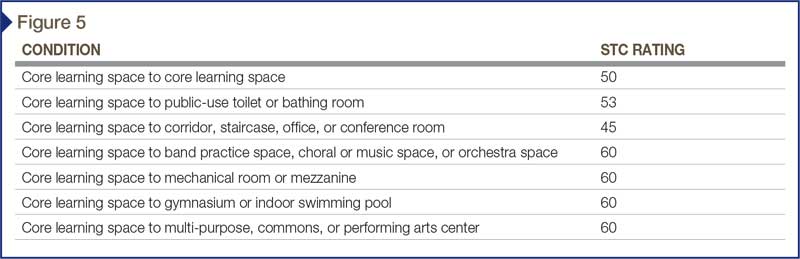

American National Standards Institute (ANSI) 12.60, Acoustical Performance Criteria, Design Requirements, and Guidelines for Schools, provides basic performance criteria for use within classrooms and other learning spaces. For core learning spaces (those where the primary functions are teaching and learning), background noise levels should be limited to an hourly average of 35 dB—if the space is smaller than 566 m3 (20,000 cf). For larger spaces, an hourly average of 40 dBA is recommended. These criteria, correlated with typical source noise levels within schools, can be used to develop STC wall performance standards between spaces. Columns one and two of Figure 5 list relevant school spaces and their required STC ratings.

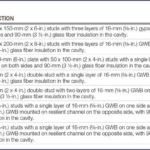

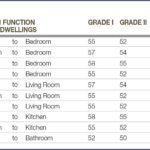

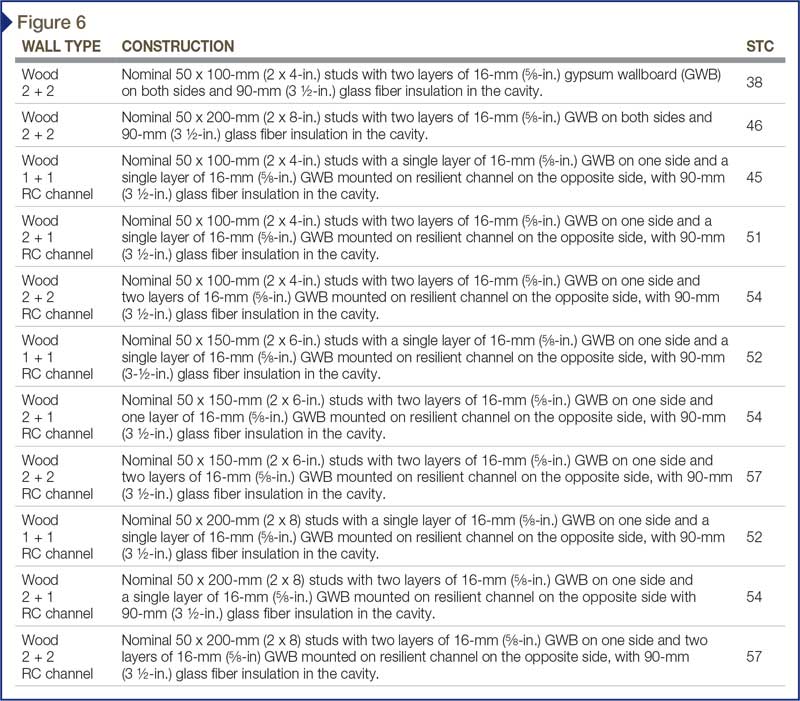

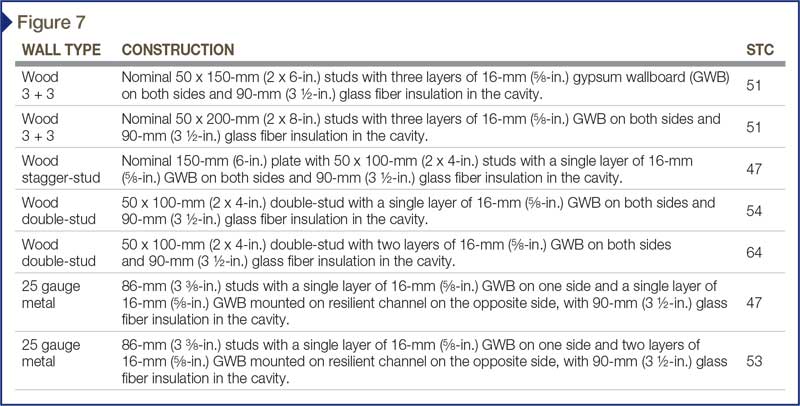

Achieving these results—especially in wood-frame construction—can be challenging without the use of resilient channel. Figure 6 and Figure 7 present a selection of assemblies and their predicted STC ratings, with and without resilient channel. For additional comparison, use of triple layers, as well as stagger-stud and double-stud construction, is also examined.

If resilient channel is not used to separate noise sources from core learning areas, the appropriate STC rating can be achieved by using more mass layers in the walls, or by creating thicker walls that provide a similar vibration break. A double-stud wall system with layers of wallboard can be used to achieve an STC above 60, but the wall thickness will need to be at least 317 mm (12 ½ in.) to do so.

Demising walls and corridor walls in residential construction

Under the standards established by the International Building Code (IBC), unit demising walls, floor/ceiling assemblies, and corridor walls should achieve an STC 50. These are minimum performance values—for most urban multi-family dwellings, a higher standard of performance is desired.

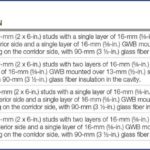

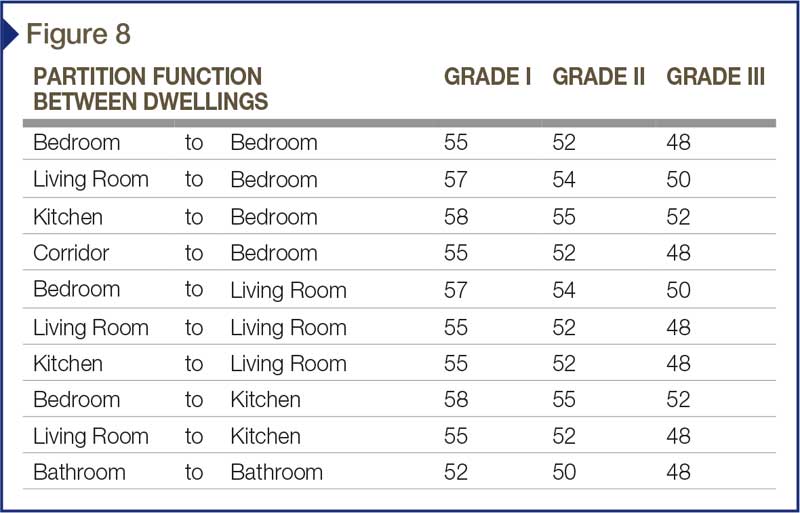

To attain the necessary STC, one must examine walls, floors, doors, windows, and mechanical and plumbing systems. Figure 8 (page 38) presents guidelines for airborne sound insulation for floor-ceiling assemblies and party wall construction. For reference, a Grade I standard requires an interior environment of 32 dBA, while the Grade II requires 37 dBA and Grade III needs 42 dBA.

It should be noted these performance levels are guidelines only and must be measured in the field. IBC standards provide a five-point allowance for a field measurement to document a laboratory-tested wall assembly.

When evaluating the condition of a demising wall between a living room and a bedroom (which requires a Grade I STC 57, Grade II STC 54, and Grade III STC 50, with an additional three-point allowance when field-constructed), it is possible to compare the wood-framed assemblies provided in Figures 6 and 7.

For demising walls with double-stud construction, structural shear layers are typically required and placed between studs. This can lower the STC performance of the assembly by eight to 10 points, due to the reduced size of the air cavity between wallboard layers. Stagger-stud construction, on the other hand, creates issues for waste, drain, and supply lines due to limited space within the wall cavity.

In a single-stud construction where structural shear walls are needed, it is possible to remove a layer of wallboard on the non-resilient channel side of the wall. However, this can only be done when the structural plywood is installed with the same level of penetration isolation given to a layer of drywall in an acoustical partition.

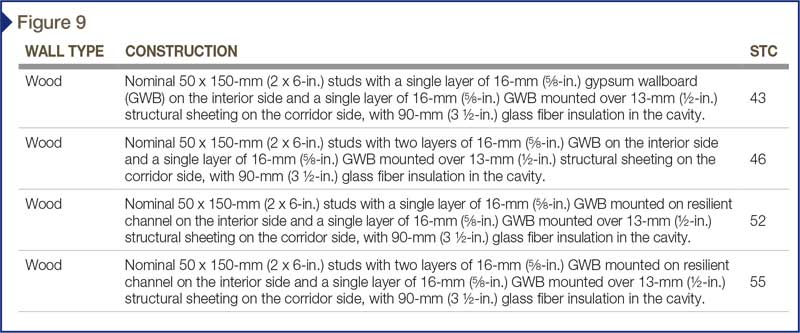

For corridor walls achieving STC 50 and higher (typically including shear wall layers and plumbing), framed wall system selection can often be resolved by using a 150-mm (6-in.) stud wall. However, expecting to achieve a field rating above STC 50 under these circumstances is impractical without the use of resilient channel. Figure 9 illustrates some potential results.

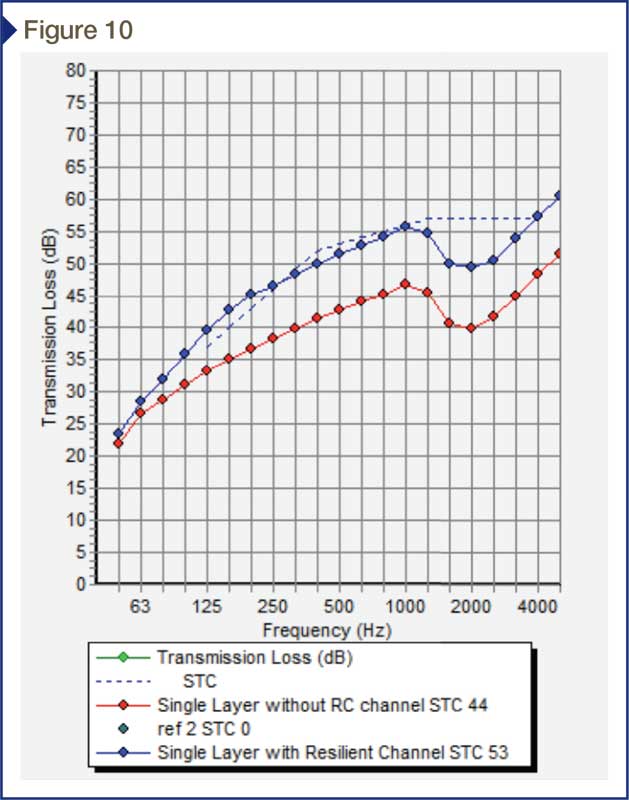

In floor/ceiling wood-framed residential construction, the application of the resilient channel becomes even more critical. A typical floor/ceiling assembly using solid lumber or I-joists falls far short of achieving the requirements of IBC. The Underwriters Laboratories (UL) L569 assembly, with 20-mm (¾-in.) gypsum topping, 20-mm plywood sub-floor, 250-mm (10-in.) solid wood joists, and a single layer of 16-mm (5⁄8-in.) gypsum wallboard, as well as 90-mm (3 ½-in.) batt insulation, achieves an STC 44. Adding resilient channel between the joists and gypsum wallboard can improve performance to STC 53, as demonstrated in Figure 10.

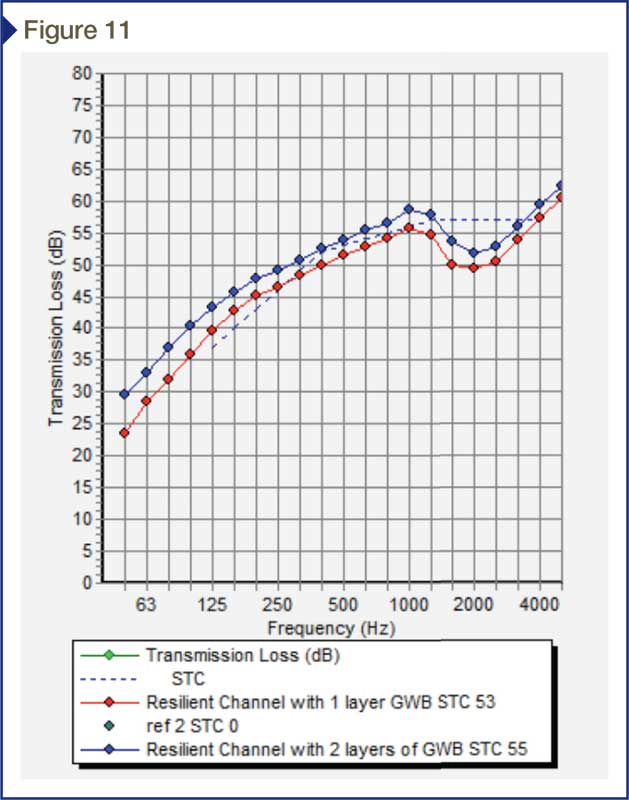

Figure 11 illustrates the improvement in transmission loss caused by adding a second layer of gypsum wallboard. This way, the STC 53 performance achieved with resilient channel and one layer of gypsum wallboard is improved to STC 55—a luxury standard in the stacked conditions of multi-family residential living.

Maximizing the benefits of resilient channel

Resilient channel can be implemented to optimal effect as long as a tested, high-performance channel is selected, and the product installed correctly. Many materials comply with ASTM C645, Standard Specification for Nonstructural Steel Framing Members, but most have not been laboratory-tested and do not provide the installation instructions necessary for building professionals to achieve the rated performances described.

Selecting the proper channel starts with the proper design. Resilient channel is 13 mm (½ in.) deep, constructed using 25-gauge steel. It has a single-leg attachment point that adds a flexural component to incoming sound waves. Resilient channel further works to break any wave received by the wallboard by creating a path that attenuates vibration. The most effective means of accomplishing this has proven to be use of the ‘dog-bone’ slot. This slot runs parallel to the channel, and is 25 to 75 mm (1 to 3 in.) long and 9.5 mm (3⁄8 in.) wide, spaced 25 to 50 mm (1 to 2 in.) apart on the sloping side of the resilient channel. Holes are centered on the slots for attachment points at 406 and 610 mm (16 and 24 in.) on center (o.c.).

Potential issues with using resilient channel

Regardless of best efforts to plan and specify, successful project completion ultimately relies on the provision of detailed instructions for the products used in construction—including resilient channel. Without careful installation of these products, laboratory performances will not be achieved. The following list of installation instructions are adapted by this author from the guidelines of various drywall and channel manufacturers. However, they are not product-specific and cannot apply to all cases. It is best to seek specific instructions to ensure full success.

1. For walls, resilient channel should be installed at right angles to studs or joists, using 9.5-mm (3⁄8-in.) type S pan head screws with flange down—except at floor level, where the channel should be installed with the flange up. This can be substituted with a 13-mm (½-in.) layer of wallboard.

2. Where resilient channel must be overlapped, splicing is necessary. This should be completed by nesting the ends of the channel directly over the framing members at the proper spacing, to align the pre-punched holes.

3. When fastening resilient channel, screws should be driven into the channels between the studs or joists. The appropriate length of screw must be selected, and the location of the studs or joists identified, before attachment of the wallboard. Screwing the wallboard through the channel to the stud or joist destroys the ‘spring’ assembly that suspends it.

4. The ends of resilient channels should be held back from the side walls to eliminate binding against the wall. Ends should also be held off the top and bottom of a wall by a distance of 100 to 150 mm (4 to 6 in.). Where baseboard is used, screws cannot rigidly attach the base of the wall to the sill plate. Similarly, at the top of the wall, gypsum wallboard cannot be attached to the header.

5. Where a wall meets a resilient ceiling, a 6-mm (¼-in.) gap should be maintained to prevent supporting of the ceiling and grounding of the resilient channel. This gap should be filled with resilient caulk, and can be finish-taped.

6. Penetrations in a ceiling or wall should maintain the performance of the resilient channel and the integrity of the assembly’s sound transmission performance. Where lighting is attached to joists, it should project through the wallboard, allowing a 6-mm (¼-in.) gap on the perimeter. This should also be sealed with resilient caulk.

7. Resilient channels should be attached to the ceiling joists at right angles, as follows: 610 mm (24 in.) o.c. for joists 406 mm (16 in.) o.c., and 406 mm

o.c. for joists 610 mm o.c. It is best to use 32-mm (1 ¼-in.) Type W or S screws, but never nails, to fasten channels to joists. Channels can be fastened to joists at each intersection with the slotted hole directly over a framing member, and should be installed with mounting flanges facing the same direction.

Gypsum board should be applied with long dimension at right angles to resilient channels and end joints staggered. Spacing of 3 mm (1⁄8 in.) should be provided between the ceiling perimeter and adjacent walls and filled with acoustical sealant. It is best to attach boards with 25-mm (1-in.) Type S screws spaced 305 mm (12 in.) o.c. along channels, and not to fasten screws through the channel into wood joists. Joints between boards should be centered over the resilient channels, or be midway between channels with joints floated and backed with sections of channels. When correctly installed, a gypsum board/resilient ceiling system will slightly ‘give’ when pressure is applied.

8. To install resilient channels on wood- or metal-framed walls, one should attach resilient channels with the attachment flange down—except at floor level, where it should face up—and at right angles to the wall studs. A strip of gypsum panel can sometimes be used at the base of a partition in lieu of the first inverted resilient channel, and should be installed at a maximum of 610 mm (24 in.) o.c. Again, it is best to use 32-mm (1 ¼-in.) Type W screws, rather than nails.

For steel stud walls, it is important to position resilient channel at right angles to steel studs, space it 610 mm (24 in.) o.c., and attach it to stud flanges with 9.5-mm (3⁄8-in.) Type S pan head screws driven through holes in the channel mounting flange. Channels should be fastened to studs at each intersection, with the slotted hole directly over a framing member. Gypsum board should be applied perpendicular to studs, with long dimension parallel to resilient channels. It is best to provide 3-mm (1⁄8-in.) spacing between the edges of boards, floor, and adjacent walls, and to fill space with acoustical sealant. Boards should be attached with 25-mm (1-in.) Type S screws spaced 305 mm (12 in.) o.c. along channels, not fastened through the channel into wood studs. Joints between boards should be centered over the resilient channels. As with ceilings, a correctly installed gypsum board/resilient wall system will slightly give when pressure is applied to it.

9. Where soffits are constructed, they must not support the ceiling, as this will cause the resilient channel to fail. Soffits should be independent elements that are suspended with resilient channel. Cabinets mounted on resilient channel walls cannot be attached through to the studs, but rather must be mounted using toggle bolts to the wallboard alone.

Conclusion

Using resilient channel makes it possible to substantially increase the transmission loss properties of a wall, with only minor changes in the assembly’s thickness and weight. In office, education, and residential construction, using resilient channel in critical-rated assemblies has become a standard for efficient use of materials and labor. Selecting a channel with good test data and installation instructions can allow building professionals to achieve the performance criteria for any project.

Bill Stewart holds an undergraduate architectural degree from the University of Maryland at College Park, and a graduate degree in engineering acoustics from the Naval Postgraduate School in Monterey. He has studied HVAC system design at the University of Washington, and is a Recognized Education Facility Planner (REFP) for the Council of Educational Facility Planners International (CEFPI). Stewart is on the 2.6 Noise and Vibration Committee of the American Society of Heating, Refrigerating, and Air-conditioning Engineers (ASHRAE), and is a member of the Acoustical Society of America (ASA) and Institute of Noise Control Engineering (INCE). He can be reached at bill@ssaacoustics.com[11].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2017/01/Resilient_Figure1.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2017/01/Resilient_Figure3.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2017/01/Resilient_Figure4.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2017/01/Resilient_Figure5.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2017/01/Resilient_Figure6.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2017/01/Resilient_Figure7.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2017/01/Resilient_Figure8.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2017/01/Resilient_Figure9.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2017/01/Resilient_Figure10.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2017/01/Resilient_Figure11.jpg

- bill@ssaacoustics.com: mailto:bill@ssaacoustics.com

Source URL: https://www.constructionspecifier.com/when-to-use-resilient-channel/

[1]

[1]

[2]

[2] [3]

[3] [4]

[4] [5]

[5] [6]

[6] [7]

[7] [8]

[8] [9]

[9] [10]

[10]