Where to find compliant NFPA 285 test data

by arslan_ahmed | June 16, 2023 11:00 am

[1]

[1]By Amy Schmidt and Eric W. Banks

Designers, specifiers, and code officials are unfamiliar with the best ways to locate information regarding National Fire Protection Association (NFPA) 285 test data and tested assemblies. This article provides guidance on how and where to find compliant tested assemblies and the extension of test data through engineering analyses.

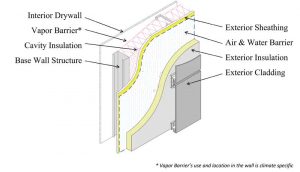

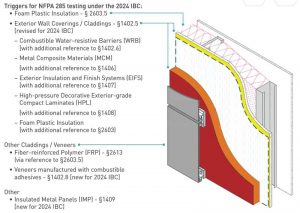

Since its inaugural edition in 2000, the International Building Code (IBC) has included requirements that certain exterior walls and exterior wall coverings shall be tested and comply with NFPA 285, Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components. Since then, both the IBC requirements and the test standard itself have continued to evolve to increase stringency, clarity, and enforceability. Changes to the 2024 Edition of the IBC help clarify compliance methods for exterior wall assemblies required to be tested and comply with NFPA 285.

Important fire performance data

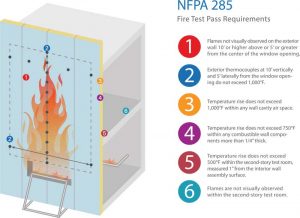

NFPA 285 test specimens are highly instrumented to record temperature data at a series of specific locations within each layer of the wall assembly and throughout the duration of the test. Depending on configuration, it is not uncommon for tests of modern exterior wall assemblies to collect data from 66, 80, or even more thermocouples.

The data collected provides manufacturers and fire experts the ability to assess how the overall wall assembly, the individual layers, and major components of the assembly behave when exposed to a prescribed fire scenario. This scenario includes a fire that starts on the interior of the building and propagates to the exterior facade. It measures the assembly’s ability to minimize the spread of fire from floor to floor and vertically and horizontally across the exterior of the building.

To many manufacturers and fire experts, the value of NFPA 285 tests is as much about the lessons learned, and fire behavior observed as it is a pass/fail test result.

[2]

[2]The specific and detailed nature of NFPA 285 test data and reports can complicate potential distribution of the information. Test reports often contain proprietary information that is not appropriate for publication. Manufacturers also find misinterpretation or misuse of test data is likely when those who are unfamiliar with the test method and fire science review these test reports and data. In practical application, testing efforts will evaluate “worst case” configurations to establish baseline assemblies for subsequent analysis and extension of test results to similar and more robust configurations.

The last several editions of the NFPA 285 test method have seen several revisions to test assembly design and reporting requirements. For example, the 2019 Edition contained several revisions that included:

- Requirements for test specimens to have at least one horizontal and one vertical joint/seam of the exterior veneer within a defined area above the window opening.

- A new prescribed procedure and materials to generically close the window head, jambs, and sill, as well as the option to use a specific closure/construction detail(s) per the manufacturer’s instructions.

- Requirements for the test report to contain drawings and a description of the construction details around the window.

Designing compliant wall assemblies

When designing an exterior wall assembly required to comply with NFPA 285, it is best to consider options from the very beginning. The design will need to meet aesthetic, energy, and moisture management requirements in addition to fire safety. Once all the performance goals of the assembly are determined, a designer can identify the materials and the configuration to use. Although one might find NFPA 285 assembly compliance information for the initial design, some flexibility may be needed when specifying materials for the project.

When determining the components for the wall design know that most assemblies will contain materials that will prompt NFPA 285 testing and compliance of the wall assembly, such as foam plastic insulation, combustible water-resistive barriers (WRBs), metal composite material (MCM) panels, and high-pressure decorative exterior-grade compact laminate (HPL) panels. The type, amount, and location of combustible components is often limited based on the tested assembly. These variables must be considered when determining NFPA 285 compliance.

Locating compliant assemblies

There tends to be two places where one may find test and design information pertaining to NFPA 285, manufacturers, and third-party directories. Manufacturers are likely to have the most current information and flexibility to evaluate potential wall designs against their available testing and engineering analyses and extensions. When conducting third-party directory searches, searches based on the various components, or products may be necessary to find a listed assembly conforming to the intended design.

[3]

[3]Test reports

Actual test data (i.e. temperature data, required observations, other measurements, etc.) is available within NFPA 285 test reports. These reports often include proprietary information that may disclose proprietary research, product, or other confidential business information that is not appropriate for the public domain. Test reports are provided to the test sponsor (the entity that initiates and funds the laboratory to perform the testing) and to any other party authorized by the test sponsor (e.g. a co-sponsor). Test sponsors are typically building product manufacturers; however, any party may engage with a testing laboratory to perform a test.

The typical use of NFPA 285 tests is to collect performance data for subsequent analysis. When combined with the almost infinite number of possible exterior wall configurations, it is unlikely one will be able to find a test report for the exact assembly (or assemblies) used on a given project. It is for this reason engineering analysis and extensions are often needed. Also, as previously noted, the amount of data and sensitivity of the contents make the distribution of test reports inappropriate.

Manufacturer information

Although manufacturers do not customarily provide the actual test reports, most will provide NFPA 285 compliance information on their websites. Manufacturers often publish various types of documents (e.g. Tech Sheets, Guides, etc.) that describe assembly details, options, and limitations based on tested assemblies containing their products. A simple internet search containing “product name or manufacturer name” and “NFPA 285” will typically lead one to this information. If one is unable to find the necessary information, has questions about it, or needs to know if a specific assembly complies, they should contact the customer service or technical assistance department.

There are several things to consider when searching manufacturers’ websites or contacting them to collect information regarding NFPA

285 compliance:

- It will be necessary to contact the manufacturer directly to make requests regarding engineering extensions of tested assemblies to address a specific project need.

- Manufacturers tend to have the most specific and necessary information about important assembly details such as window head, jamb,

and sill details and extensions of test results. - It is possible that a given manufacturer may not have all available information regarding NFPA 285 compliant assemblies containing their product (e.g. a foam plastic insulation manufacturer may not have awareness of, or access to, testing with their foam that was performed by a cladding manufacturer).

[4]

[4]Third-party certifications and design listings

Accredited1 third-party certification bodies publish searchable directories of NFPA 285 assembly listings online. These listings will typically describe the assembly design (often including drawings), components, options, and limitations. These design listings tend to be based on actual test data and some limited analysis. Third-party certification programs include verification of the materials, configuration and installation of assembly that is/was tested, as well as ongoing manufacturing and quality control (QC) inspections to ensure the product(s) manufactured is the same as what

was tested.

[5]

[5]In the building and construction space, parties holding third-party certifications (i.e. listings and design listings) are most often building product or systems manufacturers; however, there are examples of industry associations holding certifications.

Examples of accredited certification bodies currently providing design listings for exterior wall designs complying with NFPA 285 include but are not limited to:

- DrJ Engineering

- Technical Evaluation Report (TER) Directory (www.drjcertification.org/ter-directory).

- Keywords search—NFPA 285.

- ICC Evaluation Service

- Listing Report Directory (icc-es.org/building-products-listing-program/listing-report-directory).

- Standard search—NFPA 285.

- Intertek Group plc

- Intertek Directory of Building Products (www.bpdirectory.intertek.com/pages/DLP_Search.aspx).

- Standard search—NFPA 285.

- UL Solutions

- UL Product iQ (www.productiq.ulprospector.com/en).

- UL Category Control Number search—FWFO (exterior wall systems) and FWFX (exterior wall system components).

If the approaches above are not successful due to a unique assembly design, other approaches to consider include:

- Design the wall assembly(ies), then perform NFPA 285 test(s) on the design(s).

- Pro: Test data and report will match the specific assembly(ies) used for the building.

- Cons: Adds cost. The assembly(ies) might fail the test. Delays resulting from testing and, if necessary, redesign and retesting.

- Redesign the wall assembly to conform with

a previously tested NFPA 285 assembly or extension of tested assembly. - Pro: NFPA 285 compliance of the assembly(ies).

- Con: Limited flexibility in configuration and component materials. Redesign may impact other performance goals of the wall assembly (moisture management, energy code compliance, etc.).

[6]

[6]Using NFPA 285 test data for real-world project designs

Engineering analysis is the most practical and effective way to extend and apply NFPA 285 test and design data to real-world wall assemblies. As noted previously, NFPA 285 tests are typically performed on specimens that are purposely designed as a worst-case condition to allow for subsequent engineering analysis and extension. These analyses take an NFPA 285 tested and compliant wall assembly and compare it against a similar real-world wall assembly to determine if it complies with NFPA 285.

An engineering analysis will usually include a reference to the applicable NFPA 285 test and details of the tested assembly materials and configuration. It should also include clear and detailed discussion of the deviation(s) from the tested assembly and, as appropriate, why each deviation and the combined deviations from the tested assembly will not result in an assembly that no longer complies with NFPA 285. Finally, if necessary and appropriate, the analysis should include drawings to help clarify configuration details.

Two other articles with additional information regarding NFPA 285 engineering analyses include: NFPA 285—Extending Data with Comparative Engineering Analysis (IIBEC Interface, March 2021), and NFPA 285 Engineering Judgements:

A Practical Compliance Option (The Construction Specifier, June 2021).

Designers and specifiers may wish to become familiar with the 2023 edition of the NFPA 285 standard which added significant information and guidance for extending NFPA 285 test results. The guidance is found in Annex B–Guide for Extensions of Results from Assemblies that Meet NFPA 285. The Annex was developed to collect industry experience and useful practices from industry and fire experts. Development of Annex B was also intended to help improve the transparency and understanding of these analyses, including their limitations, through specific guidance for many common considerations, such as changing base walls, changes to insulation, water-resistive barrier and exterior cladding considerations, stud thickness and spacing, and many others.

Notes

1 Refer to ISO 17065, Conformity assessment—Requirements for bodies certifying products, processes, and services.

Author

In 2022, after more than 14 years in advocacy for the Dow Chemical and Dupont building and construction businesses, Amy Schmidt joined the American Chemistry Council (ACC) as director of building and construction for the plastics division durable materials team. She also leads two industry associations: the Foam Sheathing Committee (FSC) and North American Modern Building Alliance (NAMBA). These teams support the safe and effective use of durable plastic building materials in resilient high-performance applications. Schmidt, who holds a Bachelor of Business Administration from Northwood University and is certified as a LEED Green Associate, also serves on ASHRAE 90.1 main and envelope subcommittees and the International Code Council’s (ICC’s) International Energy Conservation Code Residential Main and Residential Envelope Subcommittees.

In 2022, after more than 14 years in advocacy for the Dow Chemical and Dupont building and construction businesses, Amy Schmidt joined the American Chemistry Council (ACC) as director of building and construction for the plastics division durable materials team. She also leads two industry associations: the Foam Sheathing Committee (FSC) and North American Modern Building Alliance (NAMBA). These teams support the safe and effective use of durable plastic building materials in resilient high-performance applications. Schmidt, who holds a Bachelor of Business Administration from Northwood University and is certified as a LEED Green Associate, also serves on ASHRAE 90.1 main and envelope subcommittees and the International Code Council’s (ICC’s) International Energy Conservation Code Residential Main and Residential Envelope Subcommittees.

Eric W. Banks is a technical consultant specializing in the development, physical and fire testing, certification, and codes and standards compliance of building products and their applications with

Eric W. Banks is a technical consultant specializing in the development, physical and fire testing, certification, and codes and standards compliance of building products and their applications with

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/06/buildingfiresafety_shutterstock.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/06/20171103_084829.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/06/20161202_095318.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/06/Picture4.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/06/2024-IBC-NFPA-285.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/06/NFPA-285-Fire-Test-Pass-Requirements.jpg

Source URL: https://www.constructionspecifier.com/where-to-find-compliant-nfpa-285-test-data/