Why and how to employ air curtains at industrial doorways

by arslan_ahmed | April 21, 2023 8:00 pm

[1]

[1]By Michael Coscarelli

Unprecedented market conditions and culture, partly initiated by the pandemic, created new benefits which subsequently led to an increasing demand for air curtains. For example, brick-and-mortar retail stores decentralized their inventories by switching from warehousing to a more diversified approach for in-store storage. Decentralization, especially for national chains, keeps stock closer for buyers, reduces shipping distances, and subsequently, costs. Shipping an online order to an Oregon resident is both cheaper and faster from a Portland store than it is from a warehouse in Nashville, Tennessee. Back door and front door activity for in-person returns of online orders is even more robust and in need of energy conservation using air curtains.

For decades, air curtain benefits for industrial, retail, and institutional applications included energy savings, indoor air comfort, prevention of flying insects, humidity, vehicle emissions, and particle infiltration into occupied spaces.

Likewise, construction in the warehousing industry, which has been on an 11-year growth curve, increased significantly when the pandemic hit America, according to Building Owners and Managers Association (BOMA) International. Previously, online shopping was influencing warehouse expansions. With consumers staying home during lockdowns, online buying skyrocketed, which resulted in higher shipping volumes and more energy loss potential at doors than ever before. An example of this are the challenges of protecting doorways at refrigerated warehouses, which are vital to the food supply chain. Nearly 60 percent of a refrigerated warehouse’s total cost of operation is from energy losses at doorways. Now, with energy costs skyrocketing, it is cutting deeper at the total cost of operation. Unlike conventional warehouses, refrigerated warehouses not only lose energy at open shipping doors, but also at internal freezer doors during forklift traffic.

Can an air curtain make a difference?

Unfilled job openings have increased exponentially over the course of the pandemic. Recently, limited numbers of employees needed to fill a job surplus has made workplace air comfort an important factor for corporate human resources. Employees are more apt to pick and choose employment with as many benefits as possible, and air comfort is one of them. A workplace environment which is warm in the winter and cool in the summer helps retain employees. Air curtains separate the indoor and outdoor environment at open doorways; for example, they can prevent warm air from entering the workplace in summer. In winter, air curtains can not only prevent cold air infiltration through open doorways, but they can also employ electric, steam, or hot water heating with onboard coils to maintain comfortable doorway area temperatures.

[2]

[2]According to studies, work areas which are too hot or too cold, from air infiltrating from nearby doors, can affect worker productivity. Many facility operators unsuccessfully attempt to separate indoor and outdoor environments with strip curtains, which are highly inefficient because they leak, are subjected to strong winds, and insufficiently cover the width and height of doorways. While cold or hot weather from open doorways affects worker productivity, it can also skew the manufacturing machinery and computers, as abrupt changes in the temperature decrease quality control (QC). Studies have shown temperature lowers the production activity by four percent per degree when temperatures reach 80.6 F (27 C) and above. This dramatically affects employee performance, making it hard for them to finish basic tasks. Further, working in colder environments allows for more human error and less productive individuals.1

Internal freezer doors can convert infiltrated outdoor humidity into icy floors and door hardware, resulting in daily maintenance costs and present occupational safety liabilities. Air curtains can minimize humidity transfer between refrigerated and ambient temperature areas, which is common near freezer door openings. Minimizing humidity can limit slippery floors and door hardware freeze-ups. Moisture sources may need modification before expecting an air curtain to minimize humidity challenges. Likewise, when temperatures rise above recommended levels in refrigerated storage, products can spoil, and the air curtain’s return on investment (ROI) can increase. Further, the duration of such short rises in temperature can go unnoticed, which results in spoiled products, which are serious health and safety hazards.

A new air curtain industry innovation increasing efficacy is the adaptive settings feature, which potentially boosts energy efficiency by automatically calibrating the airstream performance, in accordance with real-time local weather conditions. Adaptive settings are possible with factory engineered software since they use proprietary algorithms to determine the best volume, velocity, and uniformity (VVU) balance for the given moment. Once determined, the controller adjusts the the fan’s speed based on those current weather conditions.

[3]

[3]Smart on-board controllers and app platforms connect end-users to their commercial doorway air curtains through the internet for programming, operating, and monitoring. Pinpointing the most energy-efficient air curtain fan speeds (up to 10) helps buildings meet energy conservation, sustainability, and carbon footprint goals, while supporting thermal comfort. Further, applications have also helped the air curtain industry advance; using a smart phone, facility operators can access an endless supply of air curtains at a multitude of addresses from anywhere across the globe.

[4]

[4]Employee comfort also comes into play when insects, such as flies and yellow jackets, are prevented from entering and hassling workers. Air curtains are also a pesticide- and chemical-free way of preventing flying insects from entering interior environments—especially in food processing plants, restaurants, food service outlets, and other applications where sanitation is critical. Both the United States Department of Agriculture (USDA) and the National Sanitation Foundation (NSF) recommend air curtains because most flying insects are unable to penetrate its airstream.

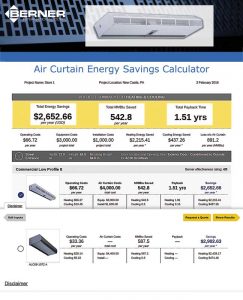

The use of energy savings calculators

Until recently, ROI was all guesstimates. Now, new advances allow manufacturers to use energy savings calculators, which are user-friendly and online energy savings estimation tools accessible from any web browser, for a quick ROI payback calculation and air curtain selection. These calculators enable facility managers, architects, consulting engineers, contractors, and manufacturer’s representatives to input their door dimensions, using times, local energy rates, and other data for energy savings.

On some manufacturer websites, these tools are free and quite advanced. Users can choose between Climate Data Online (CDO) and associated utility rates or manually enter their own weather data. Users can also manually select an air curtain model or use the embedded air curtain selector’s program suggestions. Some programs are based on loads calculated from generalized customer input, such as Typical Meteorological Years (TMY2) and the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) calculators. Hence the air curtain efficiency used to determine the payback period is based on accepted theory, laboratory, and field tests. For example, a shipping door in St. Louis, Missouri, which opens for two hours every day, would generate an energy savings of $1200 by separating the indoor and outdoor environments at the doorway with an air curtain, according to one energy savings calculator (Figure 1).

[5]

[5]Aside from an energy savings calculator, manufacturers request multiple site surveys from prospective end-users. Site survey information often includes humidity, temperature, number of doors and their dimensions, cycles per day, duration of a typical door opening, function, and other data.

Getting the most benefits from air curtains

The most important thing with air curtain installation is ensuring the selection adequately covers the doorway width and operates with enough velocity to cover the height. Within seconds of the door opening, the immediate operation of the air curtain prevents 70 to 80 percent of air infiltration into the building. Larger doors generate a quicker payback and higher ROI because of the potential for more energy losses.

The doorway height is the most common indicator for air curtain sizing. Shipping doors tend to be 3.6 to 4.3 m (12 to 14 ft) high; although there are several air curtains that can accommodate 2.4 x 2.4 m (8 x 8 ft) and 3 x 3 m (10 x 10 ft) doorway openings, including those beyond 4.3 m (14 ft) high.

[6]

[6]When properly maintained, air curtains from reputable manufacturers typically last for 20 years or more; however, not all air curtain performance statistics are reliable. When a manufacturer’s claimed specification and the product’s actual performance statistics vary, the protection of a doorway can be substandard in efficacy. For example, an engineer might specify a particular discharge cubic feet per minute (cfm), but an overstated specification in a manufacturer’s catalogue might result in poor performance, and lost energy saving potential.

The VVU of the air stream is a critical factor in an air curtain’s effectiveness; therefore, it is important for air curtains to perform up to manufacturers’ specifications. The Air Movement and Control Association International (AMCA International), a not-for-profit organization that evaluates and certifies fans, blowers, air curtains, and other air movement devices, created a test standard to assess air curtains and certify their performances. To assure an air curtain meets minimum standards, it should bear the seal of AMCA Standard 220, Laboratory Methods of Testing Air Curtain Units for Aerodynamic Performance Rating. This test is now an American National Standards Institute (ANSI) standard.

Installation and maintenance

[7]

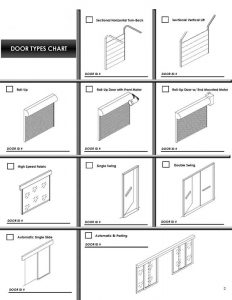

[7]An end-user can buy the best air curtain with reliable performance specifications, but if it is not installed correctly and maintained well, it will not perform up to expectations. The back of an air curtain should be installed as close to the wall as possible, and the bottom of the air curtain should be even to the top of the door opening. Due to various door opening methods, this fundamental can sometimes present installation challenges. Consequently, it is important to choose a manufacturer who can offer a multitude of accessories to circumvent obstacles and prevent potential air flow blockages. For example, protruding roll-up door mechanism cannisters across the doorway top might leave little or no room to position an air curtain in its traditional location directly above the opening. Horizontal turn-back and vertical lift sectional doors may offer the same challenges with clearance (Figure 2).

Some manufacturers provide accessories and even customize air curtain supports to fit a particular door mechanism application. Another important accessory is automation. Automatic door limit switches should be employed to avoid human intervention, such as unnecessarily turning off the air curtain. A manual override switch can offer workers activation access for air circulation or supplemental air comfort heating (if the unit has heating capabilities). Heating can also be controlled by a thermostat and delay feature.

Air curtains are easily installed, even when support accessories are required. Most facility maintenance departments, mechanical contractors, and electricians are qualified to mount and connect them. Some manufacturers with continuous construction models can ship air curtains in one piece with no assembly required, except for larger width doors, where two or more units can be combined. Most units can be installed in well under a half-day once power, steam, or hot water is supplied to the door location.

Beyond shipping doors

Pick-up doors, or sometimes referred to as pedestrian doors (0.9 m [3 ft] wide x 2.1 m [7 ft] high), where couriers deliver and pick-up small orders, can also benefit from air curtains designed for smaller opening protection duties. Most manufacturers specialize in pedestrian door air curtains because they are popular in back door operations of food service, retailers, and restaurants, as well as entry vestibules. For these establishments, they save energy, provide air comfort, minimize second-hand outdoor cigarette smoke, vehicle emission, and insect infiltration.

For more front-of-house applications where visual aesthetics are important, manufacturers also offer stainless steel cabinetry to match doorway frames or custom colors to match interiors or even corporate colors.

Notes

1 Refer to this study conducted at Cornell University in 2004, ergo.human.cornell.edu/Conferences/IEQProd01.pdf[8]

Author

Author

Michael Coscarelli has a B.A. in business and marketing from Indiana University of Pennsylvania and has been with Berner International, located in New Castle, Pennsylvania, for 37 years. He is currently the 61-year-old air curtain manufacturer’s national sales manager.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/04/Berner-Air-Curtains-Commercial-High-Performance-10-Man-Door-300-dpi-CROPPED.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/04/Berner-Air-Curtains-Industrial-Belt-Drive-30-warehouse-300-dpi-CROPPED.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/04/Berner-Air-Curtains-Industrial-Direct-Drive-20-box-warehouse-300-dpi-CROPPED.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/04/Berner-Industrial-Direct-Drive-12-and-14-Air-Curtain-Dock-Door-Photo-4-x-6.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/04/Illustration-1-Berner-Calculator-Results-Page-Demo-Proof.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/04/Berner-Air-Curtain-Industrial-supermarket-delivery-door-garage-door-and-truck-4-x-6.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/04/Berner-Air-Curtain-Application-Survey-three-pages_Page_2.jpg

- ergo.human.cornell.edu/Conferences/IEQProd01.pdf: https://ergo.human.cornell.edu/Conferences/IEQProd01.pdf

Source URL: https://www.constructionspecifier.com/why-and-how-to-employ-air-curtains-at-industrial-doorways/