Why fire sprinklers belong above suspended drop-out ceilings

by brittney_cutler | June 7, 2022 9:00 am

[1]

[1]Ten reasons to stop poking holes in ceilings

A drop-out ceiling is, “a suspended ceiling system, which is installed below the [fire suppression] sprinklers, with listed translucent or opaque panels that are heat sensitive and fall from their setting when exposed to heat,” according to National Fire Protection Association (NFPA) Standard 13 Standard for the Installation of Sprinkler Systems[2], §3.3.61. Drop-out ceilings provide an alternative to ‘poke-through’ sprinkler installations and avoid the need to install drops from sprinkler mains so sprinklers can penetrate the ceiling and discharge water into the room below. This enables drop-out ceilings to be used in situations where penetrating sprinklers are not the optimum solution.

Architectural situations

Drop-out ceilings should be considered when any of these considerations are applicable:

Cost and constructability

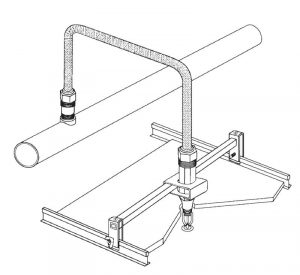

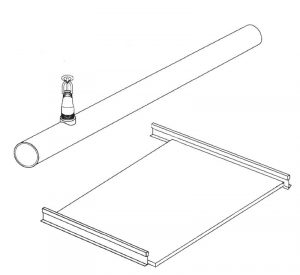

Drop-out ceiling products are cost competitive with comparable products that lack drop-out characteristics. Their economy is the result of keeping sprinklers above ceilings to reduce the cost of sprinkler installation. For example, drop-out ceilings eliminate the need to extend (drop) pipes from sprinkler mains (usually located just under a floor or roof structure) down to ceiling height. Installation is also simplified by not having to position sprinklers at the centers of panels. Non-appearance grade sprinklers can be used and finishing rings and escutcheons can be eliminated. Time required to cut holes for penetrations in ceiling panels is also eliminated (Figure 1).

In addition to these direct cost savings, drop-out ceilings can reduce job-site overhead costs. For example, installing penetrating sprinklers requires multiple, sequential steps:

- Install sprinkler mains.

- Install ceiling grid.

- Install sprinkler drops in center of grid spaces.

- Install ceiling panels.

- Install sprinkler heads and trim.

Installing drop-out ceilings, on the other hand, requires just two steps:

- Install sprinkler system.

- Install ceiling beneath sprinklers.

Since ceiling installation typically occurs late in a project, simplifying coordination of sprinklers and ceilings can shorten the critical path to complete a project. Drop-out ceilings also makes good economic sense during renovation projects by allowing a ceiling to be installed without having to modify existing sprinklers (Figure 2).

A detailed cost comparison of penetrating sprinklers and drop-out ceilings is available online, at bit.ly/dropout_cost.

[3]

[3]Aesthetics

Some penetrating sprinklers are fully exposed beneath a ceiling. Where this is not visually acceptable, specifiers can call for semi-exposed (recessed) sprinkler heads, or concealed heads. Concealed sprinklers have a cover plate that will drop-out when exposed to heat from a fire. The wide-spread acceptance of drop-out sprinkler covers should inspire confidence in the viability of drop-out ceilings that function according to similar principles.

While concealed sprinkler covers are nearly flush to bottom of ceiling surface and can have a color similar to the ceiling, they are not truly concealed; they can be seen from below when viewed at typical ceiling heights and lighting. The cover and ceiling texture can vary, and covers can be especially visible if care is not taken to center sprinklers in panels and install them at uniform intervals. The covers add to the visual clutter of air diffusers, light fixtures, sensors, public address speakers, and other services that detract from the appearance of a ceiling.

Keeping sprinklers completely above drop-out ceilings eliminates sprinklers as an aesthetic concern.

[4]

[4]Luminous Ceilings

NFPA’s definition of drop-out ceilings incudes the possibility of using translucent materials. This is not coincidental, as the history of drop-out ceilings began with the search for better luminous ceilings. These ceilings were a signature of many midcentury modern buildings, made possible by the growing affordability at the time of fluorescent lamps and lightweight translucent thermoplastics. When architects objected to the shadows penetrating sprinklers cast on the pristine light-emitting surfaces, engineers determined how thermoplastic panels could be installed beneath sprinklers, and the drop-out ceiling was invented.

There has been a resurgence of interest in luminous ceilings, sparked in part by the proliferation of light-emitting diode (LED) lighting solutions. At the Bavaria Downs banquet center in Chaska, Minnesota, for example, red, green, and blue plus white (RGB+W) LEDs are digitally controlled to change the color and appearance of the back-lit ceiling. Sprinklers remain out of sight, above the LED strips and do not cast shadows onto the ceiling.

Room-within-room

There are many occasions when a ‘roof’ must be put over a space that is within a sprinklered building. Examples include:

∞ A big-box store or shopping center that uses a store-within-store concept to create a boutique with a lowered ceiling and a more intimate ambience (Figure 3).

∞ An office or lab on a factory floor that needs to be enclosed to control dust, temperature, or other environmental factors.

∞ A meeting room within an open office that needs a covering for increased privacy, better illumination, or to create a better sense of place.

∞ A canopy over a display within a convention center, gallery, or museum (Figure 4).

[5]

[5]A drop-out ceiling avoids the need to install separate sprinklers within the enclosed space. Light-transmitting panels also permit the use of borrowed light from overhead luminaires.

Soffits and ceiling clouds

Like a room-within-room scenario, drop-out ceilings can eliminate the need to install sprinklers both above and below the ceiling, and can also be used for creative lighting.

Data farms

Clear drop-out ceilings are frequently used in computer server facilities to create energy-saving cold-aisle or hot-aisle ventilation systems. The ceilings are installed between rows of computer racks so the aisles can be used as air supply or exhaust ducts (Figure 5).

Environmental separation

Dust, grease, and other contaminants can collect on penetrating sprinklers; cleaning requires care to prevent damaging sprinklers. More, the holes cut for penetrating sprinklers create openings that permit the passage of air, insects, dust, and other matter that can compromise the energy efficiency, hygiene, and cleanliness of the covered space. While the gap around each sprinkler penetration is small, their aggregate effect can be detrimental. This is especially important for ceilings in areas with strict requirements for cleanliness, such as food preparation and healthcare.

[6]

[6]Another form of environmental separation has to do with heat stratification. Hot air rises, making it difficult to warm occupants at floor level, especially in spaces with high structural ceilings. Installing a suspended ceiling reduces the volume of air requiring heating, thus saving energy, and reducing costs. Drop-out ceilings simplify the installation of suspended ceilings in existing sprinklered areas with high structural ceilings.

Differential movement

The pipes in a sprinkler system are more rigid than a ceiling’s suspension wires and lightweight grid. Differential displacement due to seismic, settlement, or other movement can damage sprinklers or ceiling panels (Figure 6).

The potential for damage can be ameliorated by using flexible drops that may add to the cost of construction. Another approach is to oversize the holes through which sprinklers penetrate to allow for anticipated movement; this practice, however, reduces the ceiling’s effectiveness as an environmental separation as discussed in the preceding comment.

Alternatively, the potential for damage can be eliminated altogether by decoupling the sprinklers from the ceiling by using a drop-out ceiling.

[7]

[7]Maintenance

A suspended ceiling panel may be removed (and then reinstalled) to allow access to the interstitial space above the ceiling, to be cleaned, or to be replaced. Penetrating sprinklers complicate this work and require extra care to extricate panels from sprinklers without damaging either. Drop-out ceilings offer on-going advantages for building maintenance.

Abuse or accidents

Penetrating sprinklers can be damaged by accidental impact, careless maintenance, or by malicious tampering. Locating sprinklers above drop-out ceilings may not eliminate incidents but will keep sprinklers out of the way of damage and out of sight of potential vandals.

Types of drop-out ceilings

Thermoformed panels

[8]

[8]The original type of drop-out ceiling remains the system with the longest history of performance and for which the most technical data is available. Panel designs from one of the original manufacturers are still made, molded from rigid vinyl that is either 0.33 or 0.76 mm (0.013 or 0.03 in.) thick. When heat from a fire raises the air temperature at the ceiling to approximately 49 C (120 F)—hotter than temperatures in commonly occupied spaces and less than the temperature required to discharge the sprinklers—the lightweight thermoplastic softens and sags, then falls intact and harmlessly to the floor. The heat then rises to the height of the sprinklers and causes them to discharge.

Rigid vinyl has good fire resistance characteristics, and the panels are rated Class A when tested according to ASTM E84 Surface Burning Characteristics of Building Materials and Flame Class V-0 per UL 94 Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances. They are the subject of an evaluation report from the International Association of Plumbing and Mechanical Officials-Uniform Evaluation Service (IAPMO-UES) for compliance with International Building Code (IBC) requirements, and have additional listings and approvals from UL, Factory Mutual, and the California Fire Marshal.

[9]

[9]The listings and approvals specify the panels can be used with either standard response or quick response sprinklers that operate at 57 C (135 F) or above and with either dry or wet pipe systems. Sprinklers must be installed no less than 25.4 mm (1 in.) and no more than 1.5 m (5 ft) above the drop-out ceiling panels. They are acceptable in light hazard and Group 1 ordinary hazard occupancies as defined in NFPA 13 and in Seismic Design Categories B, C, D, E, or F. They can be used with or without uplift-prevention clips, and with suspension grid tees that are either 24-mm (0.94-in. [nominal one inch]) or 14-mm (0.56-in. [slim line]) wide.

The thermoformed panels have molded decorative relief and are available in a variety of colors, faux finishes, and light transmitting materials. They are approved for use with acoustical backings that provide noise reduction values as high as NRC = 0.85. They are Greenguard Gold certified for low volatile organic compound (VOC) emissions, made with up to 100 percent recycled-material content, and disclose ingredients in a Health Product Declaration. The panels are lightweight, easy to install, durable, strong, stain resistant, unaffected by water, and washable[10].

Expanded polystyrene (EPS) panels

Drop-out ceiling panels made from EPS[11] foam are typically called ‘melt-out ceilings.’ The fact EPS melts complicates their fire-safety performance. The EPS Industry Alliance states, “When installed correctly, expanded polystyrene products do not present an undue fire hazard.” It also recommends, however, “…that expanded polystyrene should be protected by a thermal barrier in specific applications as referenced in [applicable codes].” This limit the occupancies in which EPS ceiling panels can be used.

[12]

[12]Nonetheless, some EPS panels are listed by insurance companies based on testing in accordance with UL 723S Drop-Out Ceilings Installed Beneath Automatic Sprinklers. They have either a flat or molded white surface. The 16 kg/m3– (1 pcf-) density foam from which they are made has limited strength or durability. They do not offer noise reduction value and can be used only with standard response sprinklers.

Stretched ceilings

These ceilings use fabric that is stretched to provide a taut, flat ceiling surface that is held in place with perimeter gripping devices. The fabric panels are assembled with heat-sensitive stitches or seams. When exposed to heat, the seams become undone and tension in the stretched ceiling pulls the seams apart to expose sprinklers.

Some manufacturers use panels of translucent polypropylene fabric to make suspended covers that protect interior spaces from dust and contamination generated by reroofing or other overhead work. The fabric can also be used to form temporary partitions to create isolation areas for operations needing segregation from the rest of a space. These products are tested according to UL 723S and have an IAPMO-UES evaluation report recognizing its use as a drop-out ceiling. The report limits the product to temporary use of up to 180 days. Each installation is engineered and installed by the product’s manufacturer (Figure 7).

Several companies offer fabric systems used primarily in theatrical and exhibition installations. They use woven, synthetic textiles with fusible seams 305 mm (12 in.) on center. When the fabric reaches 71 C (160 F), the stretched knit contracts into small, bunched lines of material. This opens more that 70 percent of the ceiling area allowing heat to reach the sprinklers. Products in this category claim flame resistance but do not offer code evaluations regarding drop-out performance; consult authorities having jurisdiction for applicability to ceiling use.

While stretched fabric ceilings can be pulled back for access above the ceiling, they do not provide access as easily as panels in a ceiling grid. On the other hand, the stretchability of the fabrics allows for a modicum of curved surface and interesting architectural effects. Some of the fabric products can be easily printed upon to create stunning graphics.

Electro-mechanical operations

There are also ceiling panels that drop-out when an electro-mechanical latch releases in response to an electronic signal. While more expensive than the other options, they are useful where the ceiling must drop-out due to smoke detection or other trigger besides temperature rise.

Specifying tips

Each drop-out ceiling product has distinct characteristics, making it imperative to study its code evaluation service report or listing and the manufacturer’s installation instructions. Having the evaluation service report or listing will not only guide specification and installation, but it will also be invaluable if a building or fire authority having jurisdiction has questions about a product.

Each type of drop-out ceiling is compatible with only certain types of fire sprinklers and will have limits regarding the maximum and minimum height of the sprinklers above the ceiling. Further, they can be used only in the types of building occupancies included in the listing.

Unless otherwise permitted in a listing, drop-out ceilings should not be used in stairs, exit corridors, or paths of egress. Neither should they be used above nor adjacent to stoves, ovens, or other hot equipment. They cannot be part of a fire-resistance rated floor-ceiling assembly or an air distribution plenum. Further, they may be inappropriate for spaces requiring a high degree of sound isolation; the best available sound transmission classification for a drop-out ceiling is STC 18.

Ceiling products used for drop-out ceilings can also be used with penetrating sprinklers but may require special provisions to prevent ceiling panels from getting hung-up on and interfering with the operation of sprinklers in the event of a fire. There are two methods, for example, for using penetrating sprinklers with certain thermoformed panels:

∞ Sprinklers are installed through holes 6 mm (0.25 in.) larger in diameter than the outer diameter of the sprinkler and trim ring (if used) to enable tiles to fall from the ceiling grid without becoming entangled with the sprinkler, or

∞ 0.76-mm (0.03-in.) thick panels backed by mineral fiber panels can be used with penetrating sprinklers when installed in accordance with instructions.

Listings typically impose requirements for the type of suspension grid and installation accessories, prohibit painting of surfaces, and stipulate other conditions of use.

Project specifications should cross-reference the ceiling and sprinkler sections. It may be helpful to note the use of drop-out ceilings on project drawings to make sure bidders are aware of the applicable requirements.

Building owners and tenants must understand drop-out panels removed from a ceiling may be replaced only with another drop-out panel. Plaques stating this requirement should be installed in visible locations above the ceiling or at the sprinkler riser.

Successful use of a drop-out ceiling depends on communication among project designers and engineers. The former may be primarily concerned about ceiling aesthetics and performance, the latter with the layout and code compliance of the fire suppression system. Too often, the project team defaults to penetrating sprinklers without considering other options. They—and the building owner—may find the benefits of drop-out ceilings justify their consideration during the design development or early construction document phases of design.

Authors

Ed Davis is president of Ceilume, a leading manufacturer of thermoformed ceilings. He leads their fire testing and code approval efforts.

Ed Davis is president of Ceilume, a leading manufacturer of thermoformed ceilings. He leads their fire testing and code approval efforts.

Ben Carr is the customer service manager at Ceilume and has 16 years of experience helping customers find ceiling solutions. He can be reached at pro@ceilume.com.

Ben Carr is the customer service manager at Ceilume and has 16 years of experience helping customers find ceiling solutions. He can be reached at pro@ceilume.com.

Michael Chusid is an architect and Fellow of the Construction Specifications Institute (CSI) and a marketing consultant to building product manufacturers.

Michael Chusid is an architect and Fellow of the Construction Specifications Institute (CSI) and a marketing consultant to building product manufacturers.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/05/Ceilume-SprinklerAboveLumionusCeiling-from-above.jpg

- Standard for the Installation of Sprinkler Systems: http://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=13.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/05/Ceilume-SmallBatchOrganics-SprinkerAboveCeiling-BackgroundSoftened.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/05/Schematic-Penetrating.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/05/Schematic-DropOut.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/05/Ceilume-BavariaDowns-Green-02.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/05/CeilumeLuminousCeiling-Nestle-NewPark-Detail-Edit-2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/05/Ceiling-Cloud-AlaskaAirline-LAX.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/05/www.learningfromearthquakes-Enhanced.jpg

- washable: http://www.constructionspecifier.com/a-rational-approach-to-ceiling-product-evaluation.

- EPS: http://www.epsindustry.org/building-construction/fire-resistance.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/05/5-test-chamber-panels-falling-Enhanced-Edit-Edit.jpg

Source URL: https://www.constructionspecifier.com/why-fire-sprinklers-belong-above-suspended-drop-out-ceilings/