Constructability and detailing

There are key differences between window products and storefront or curtain wall products in window wall applications. Specifics on how these different systems are designed, detailed, and constructed are beyond this article’s scope, but the following paragraphs highlight some critical design elements and differences that must be considered.

Anchorage

Curtain wall products offer inherent flexibility in how the glazing system is constructed and where it is structurally attached, often using clips that either are slotted or slide within the vertical mullions to accommodate differential movement (Figure 2). This allows the curtain wall anchorage to be more easily customized to suit project-specific conditions. Meanwhile, window products in window wall applications are more sensitive to concrete tolerances, since they are almost always gravity loaded at the sill, with lateral support at the head that should be designed to accommodate differential building movement, such as by utilizing a receptor frame or slotted anchors (Figure 3). (For more, see the article by Derek McCowan and Michael Louis, “Window Receptor Frames: What You Need to Know,” which appeared in the June 2007 issue of RCI International’s Interface magazine.)

It is important all perimeter frame anchors be coordinated with the building structure and structural engineer to confirm whether steel embeds or additional structural supports are required. This also helps ensure fastener embedment depth and edge spacing do not pose conflicts with the building structure (such as tendons for prestressed or post-tensioned slabs) or anticipated movements.

Positioning

Traditionally, perimeter framing for window wall systems was positioned along the slab edge or on top of the backup wall structure (i.e. knee wall), where the support and attachment is straightforward. As energy codes evolve and performance expectations advance requirements for increased thermal insulation in opaque exterior walls and reduced thermal bridging in exterior walls, building designs are increasingly pushing window wall components further outboard of the rough opening (i.e. past the slab edge or knee wall) in order to align the insulated glazing with the exterior cavity insulation to the greatest extent possible (Figure 4). While this configuration maximizes thermal performance to mitigate risks of condensation and increase occupant comfort in the proximity of the glazing system, it also impacts the structural support conditions and perimeter detailing for each family of glazing system products.

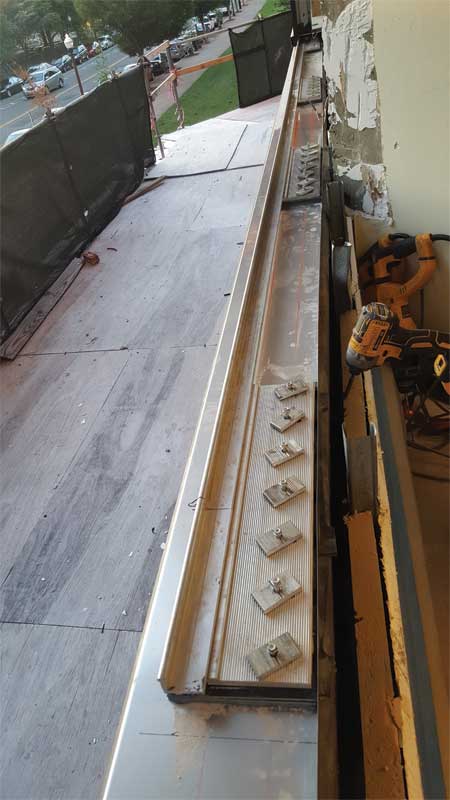

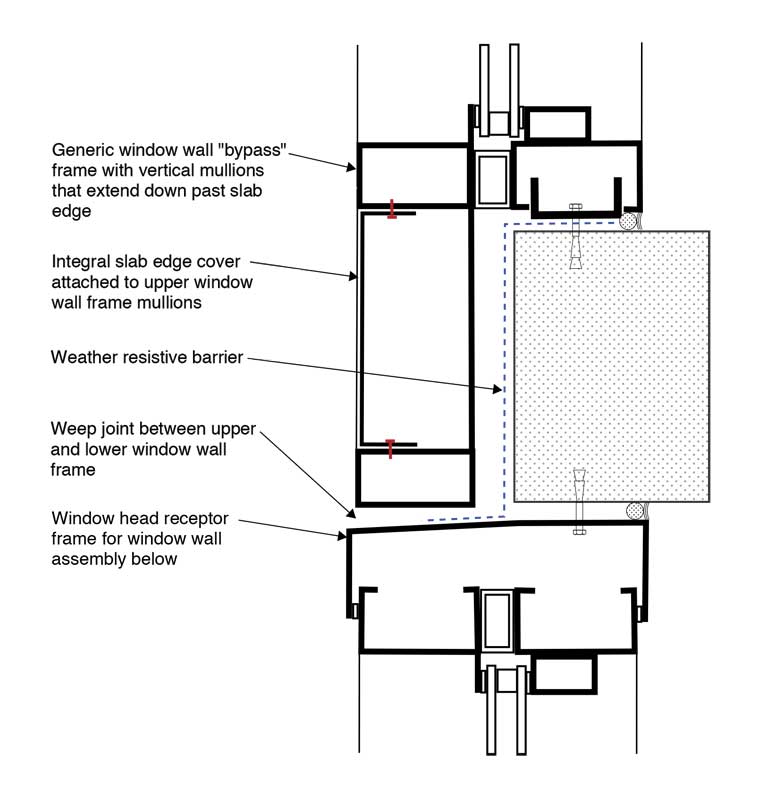

The support conditions and perimeter detailing required to successfully integrate with the adjacent weather-resistive barrier (WRB) varies depending on the type of glazing system product, and the field work required to construct the perimeter detailing can have a substantial impact on the overall installation sequence and installed cost. Recently, more manufacturers have been developing window walls with ‘bypass’ frames (Figure 5) that allow the front portion of the glazing assembly to sit proud of the slab edge or backup wall structure without requiring additional support, and that incorporate integral slab-edge covers or spandrel panels into the system between stacked window wall sections to alleviate some of the slab-edge detailing and coordination.

Slab-edge detailing

Traditional curtain wall applications are generally installed outboard of the slab edge and are continuous past the floor line (Figure 6). Window wall applications, on the other hand, typically include glazing systems installed continuously—floor to ceiling—between slabs to maximize daylighting and occupant visibility while minimizing requirements for fire blocking or fire-resistant insulation at the slab edge. Positioning window walls between the slabs also allows the glazing system to be primarily installed from the interior. This limits the amount of exterior access required to complete the glazing system installation, which is often desirable to contractors and owners since it is perceived as providing flexibility in the construction sequence and scheduling.

However, it is important to keep in mind exterior access is still required to install and integrate the exterior wall components at the slab edges separating window walls, or at perimeter transition details to other cladding systems on the same floor level (Figure 7). The authors find the slab-edge components in particular—WRB, perimeter seals, exterior insulation, and cladding—are often overlooked or considered an afterthought when evaluating the different glazing system options (e.g. continuous curtain wall outboard of the slab versus window wall applications spanning between slabs). Nevertheless, these components warrant considerable evaluation and care when selecting an appropriate glazing system given their significant impact on both design (e.g. detailing, air/water barrier continuity, and water management and construction (e.g. sequence, access, and coordination with multiple trades).

Vertical mullions and sightlines

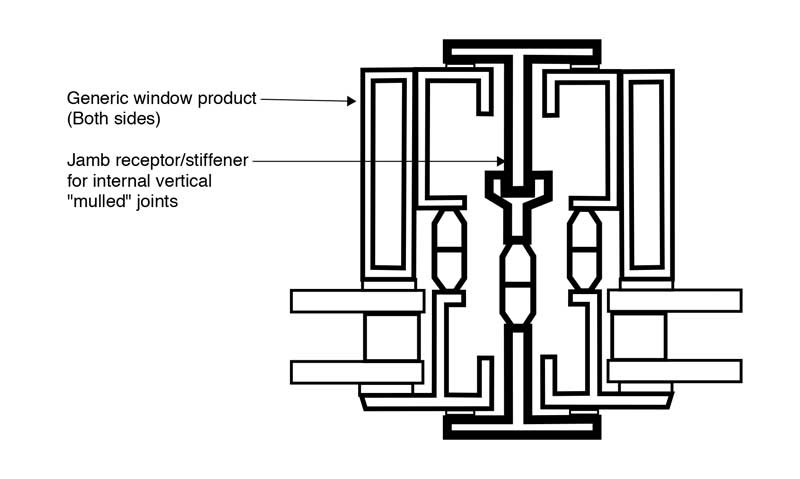

Glazing designs with zero sightlines, such as butt-glazed or structurally sealed vertical mullions, typically cannot be constructed with window products in a window wall application, and instead require a curtain wall product. Similarly, concept designs with 45-degree corner mullions at inside or outside corners typically require a curtain wall product in a window wall application. This is because window wall systems made with window products are ‘mulled’ together, where the individual window frames utilize male/female frame extrusions that can engage the adjacent window frame.

For tall spans, some window products may require a three-piece mullion consisting of a center structural mullion that receives the window frames on each side (Figure 8). Ultimately, these mulled joints between window products can create larger sightlines at the internal vertical mullions than storefront or curtain wall products and are a potential weak point for air and water infiltration, which otherwise must be managed by the perimeter receptor frame and associated flashings and seals.

Air and water management

There are fundamental differences in how window, storefront, and curtain wall products manage air and water. Often, window and storefront products do not include the drained and pressure-equalized glazing pockets that are integral to most curtain wall systems. Therefore, continuous sill pan flashings are commonly recommended for below window and storefront products, but can be unnecessary and sometimes excluded in curtain wall systems.