The joists were more shallow than typical, being 241 mm (9 1⁄2 in.) deep instead of 302 mm (11 7⁄8 in.). This placed additional restrictions on the number and size of holes. However, use of the software upfront allowed for pre-planning to ensure crews knew exactly where to install lines, avoiding field calculations while helping to avoid mistakes and costly repairs or replacements.

Rethinking framing members and bringing in the whole team early on is certainly a shift in approach for many builders and installers, but it is a necessary step that has helped the builder improve future building performance.

Similarly, a Bethesda, Maryland-based residential developer used software as part of its efforts to refine its building processes. In anticipation of impending energy code changes, the developer began evaluating a range of strategies to meet new mandates. With the assistance of the Home Innovation Research Labs under the umbrella of the Department of Energy’s Building America program, this effort culminated in the construction of a test house approximately 45 percent more efficient than the requirements of 2006 IECC.

A number of measures were implemented to boost energy savings, including better air sealing and insulation, and the overall structure itself was re-evaluated. Most notable was a switch to advanced framing, including 609-mm (24-in.) on-center (oc) wall spacing that helped cut down on materials and installation time while providing increased cavity area for more robust insulation. Advanced framing also meant fewer I-joists to cut through to run HVAC.

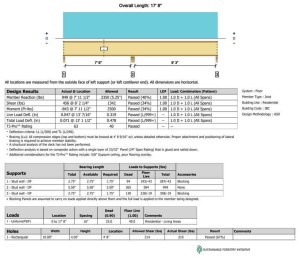

Transitioning to a new framing system and accommodating new mechanical routes required bringing trade partners on board well in advance to plan—and to firmly establish buy-in on the vision and mission. To design the framing system, a design team and third-party engineer worked with their trade partners and a wood products manufacturer. With the aid of framing software modeling tools the layout, including the most efficient placement for ductwork, plumbing, and wiring, was designed. The entire framing system was pre-cut with a computer-aided system, labeling components with an ink-jet printer to simplify assembly onsite.

Moving ductwork out of the unconditioned attic allowed the size of its HVAC system to decrease, while lessening requirements for duct insulation. With that change, the decision to pre-cut was an easy one.

Conclusion

As demand, government regulation for more energy-efficient buildings, and market competition continue to climb, improving performance and reducing waste within the HVAC system may not be optional. Moving heating and cooling from the attic into the energy envelope is one that takes planning and foresight, but reaps the rewards of cost savings for the occupant through decreased energy loss and smaller requirements for overall HVAC capacities. Software solutions and pre-cut framing packages ease the burden by pre-planning for mechanical installation through I-joists, ensuring proper placement, installation, and long-term HVAC performance.

Jeremy Dummer is a technology advisor for Weyerhaeuser. He has worked with the company for 16 years and in his current role he consults with building material designers to maximize software technologies and successfully integrate programs into various operations. Dummer can be contacted via e-mail at jeremy.dummer@weyerhaeuser.com.