Background

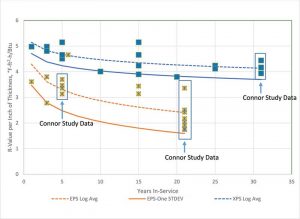

The Connor study builds on the landmark Alaska study by Esch and the Pouliot and Savard research for the Ministère des Transports du Québec (MTQ). Prior to the Connor study, the longest-exposed, in-situ XPS sample was 25 years in service, and the longest-exposed EPS sample was only 15 years in service. Combining data points from Esch, Pouliot and Savard, and Connor, the total number of data points for XPS and EPS was 18 and seven, respectively. The Connor study provided additional data for EPS and XPS insulation, especially at a longer service life, allowing for an updated comparative assessment over a similar range of years in service.

Earlier studies

The Esch study (1986) looked at 14.7 lane-miles of roadways and 2972 m (9750 ft) of airfield runway constructed by the Alaska Department of Highways in order to control frost heaving and permafrost thawing. Insulation materials were installed below-grade in these applications in the late 1960s and extracted around 1984 for evaluation. The EPS samples were three and 15 years old and the XPS samples were three, five, 10, 15, 20, and 25 years old.

The Pouliot and Savard study (2003) later evaluated an experimental test roadway section approximately 385 m (1263 ft) long in Saints-Martyrs-Canadiens, Québec, Canada. Insulation was used to reduce the effects of seasonal freezing and thawing. In this application, the insulation was intended to prevent freezing of the road bed substrate. The study compared uninsulated roadway sections with insulated roadway sections using XPS and EPS insulation.

Frost heave of roadways and airport runways can cause significant cracking, undulations, ruts, and roughness. The MTQ study included an array of measurements of the road quality including surface distress, roughness, and bearing capacity. Measurements were made of rut depths. Roughness was measured by the International Roughness Index (IRI). Falling weight deflection (FWD) measurements were made as well.

Most importantly, data points were obtained for moisture content and thermal conductivity of the extracted XPS and EPS insulation. The latter measurements were relevant to the Connor study, which included similar data collected from beneath roadways and airfields in Alaska. The roadway of the MTQ study was constructed in 1995 and the XPS and EPS materials were extracted after one, three, five, and seven years in service.

EPS to XPS thickness ratio

When evaluating insulation options for demanding below-grade applications, a ‘thickness ratio’ of EPS relative to XPS, where each option may be expected to deliver comparable thermal performance over the long-term, can be a practical tool.

The recommended EPS insulation thickness is obtained by multiplying the required XPS thickness by an EPS/XPS thickness ratio. For example, if the engineering design requires 100 mm (4 in.) of XPS, and the recommended thickness ratio is 1:5, then the engineering specification should require 150 mm (6 in.) of EPS. In the 1986 Esch study, the recommended thickness ratio was 1.36. In the 2003 Pouliot and Savard report, the recommended thickness ratio was 1.20. In contrast, the Connor study suggests increasing the thickness of EPS by 1.5 to two times the thickness of XPS. An EPS/XPS thickness ratio typically is derived from existing design documents such as the American Society of Civil Engineers (ASCE) 32, Design and Construction of Frost-Protected Shallow Foundations. For insulation installed in the horizontal orientation of frost-protected shallow foundation applications, ASCE 32 and the International Residential Code (IRC) recommend a thickness ratio of 1.43 for Type IX EPS with R-2.8 compared to Type IV XPS with R-4. These insulation types have similar densities in ASTM C578. This calculated thickness ratio of 1.43 is based on an extensive literature review (consult “Below-Ground Performance of Rigid Polystyrene Insulation: Review of Effective Thermal Resistivity Values” by Jay H. Crandall, 2010).

The thickness ratio of 1.43, as prescribed by ASCE 32, accounts for the uncertainty in the efficacy of foundation drainage measures and the possible occurrence of more severe ground conditions. Along with the two earlier studies, the Connor report further informs these prescribed thickness ratios. The severity of ground conditions varies from site to site and is exacerbated with in-service years.

The Connor study

The Connor study provides new long-term, in-service data offering insight into the moisture performance of past and recent EPS and XPS products. The data shows the thermal and moisture performance of newer EPS products (after about five years in service) tracks well with older EPS products. The new data provides added confidence the current thickness ratios as prescribed in ASCE 32 as well as the Esch and the Pouliot and Savard studies are valid, or even underestimated the decrease in EPS thermal resistance over time. The data continues to validate the superior moisture and thermal performance of XPS products in below-grade applications.