by Kristen Lewis

Insulating walls with low-pressure sprayed polyurethane foam (SPF) is a common practice among builders and architects for various reasons—such as increased energy efficiency, structural support, and overall comfort. One of the ways SPF can increase the comfort of a structure is through the material’s sound-deadening properties, which contractors can employ to bring additional value to a project.

Sound-deadening sprayed polyurethane foam in a building can serve several purposes, from mitigating outside noise to enhancing a quiet office space. Multimedia environments, or any specialty rooms where excessive noise can become an issue, can also benefit from SPF as a cost-effective sound-reduction measure.

Traditional sound barrier technology often used within structures—such as vinyl sound barriers and fiberglass products—can be cost-prohibitive for builders or property owners looking to save money or to spend it elsewhere—a ‘nice-to-have,’ though not a ‘necessary’ feature. When builders and architects take advantage of sprayed polyurethane foam insulation for other uses, its sound-deadening effects can come as a bonus, saving time and money in the construction process while increasing the structure’s comfort.

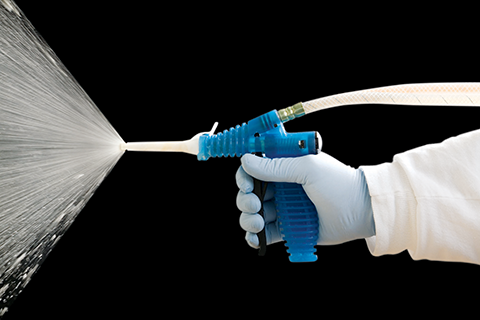

Application of SPF for sound deadening

Several manufacturers offer sprayed polyurethane foam specifically with this acoustic quality in mind. Open-cell sprayed-foam formulations—which are lower density and often less expensive per board foot than closed-cell counterparts—are well-suited to sound-deadening, with high expansion properties to quickly and simply fill voids.

Sprayed polyurethane foam as a sound-deadening measure works for essentially the same reason the material works for mitigating airflow: sound is airborne. By filling wall voids, the foam curbs resonance, keeping the sound from leaving or entering the desired room or space. Sprayed foam can also reduce sounds generated inside wall spaces, caused by flushing toilets, clanging pipes, and other miscellaneous utilities.

Applying sprayed polyurethane foam as a sound barrier, however, differs slightly from applying the product strictly as an insulation material. When used strictly as insulation, effective spots to insulate for thermal efficiency include rim joists, attics, and crawl spaces, as well as the traditional wall application. Sound-barrier spray-foam products should be applied to interior walls throughout areas that typically produce excess noise as noted by the property owner—these can often be interior walls rather than exterior assemblies. Working in conjunction with the building occupant to identify the specific areas where noise control is important to them is a critical part of the process to ensure the best result.

No matter the application, all regular safety precautions must be adhered to when applying sprayed foam. The U.S. Environmental Protection Agency (EPA) outlines several key steps for safe polyurethane foam use. These precautions include:

- review the product label for recommended work practices and precautions;

- read through the ventilation guidelines for the product; and

- prevent eye, skin, and inhalation exposures with the appropriate safety gear (e.g. goggles and respirators); and

- exercise caution when determining safe re-occupancy after the polyurethane foam has been applied. EPA recommends allowing the foam to completely cure before re-entry by unprotected persons.

Re-occupation of a space is also contingent on cure times. Additionally, ensuring installers have allowed for the proper cure time length ensures the foam has set properly, and will perform its intended function well into the future.

I think it’s cool that spray foam is also good for sound proofing as well as normal insulation. Being a guy who is heavily involved in music, it would be nice to have sound not travel to far out of my house. I already bother my neighbors enough!

Wow, this is amazing. I didn’t realize that spray foam could be used for sound proofing as well. Really good to know, thanks for sharing!

It should be clarified that the use of spray foam for acoustic purposes is mainly only effective within a closed wall and it acts primarily as a sound deadener or acoustic mass, not a sound absorber. To be more specific, if one is looking to attentuate or absorb the sound within a space, spray foam is not very effective for absorption of sound. Rather, the foam within the wall minimizes the ability of the sound to pass through the wall through resonance (i.e. vibration). To absorb the sound, one would need to use an absorptive material like an acoustic wall panel, acoustic ceiling or carpet.

Paul, any idea for soundproofing, or at least a way to substantially reduce noise between condo interior walls? I’m looking for safe low VOC air qualify, fire proof or retardant and not too expensive way to prevent voices from traveling between units in a town house.

Thanks, Mike

I am looking for a SPF that is primarily used for acoustic dampening and absorption. If anyone knows of a brand that has a high density (mass per cu.ft.) and is visco-elastic when cured, please leave comment. It does not need to be high expansion.

This is very helpful. Might try this.

Hi All,

STC and NRC mostly deals with airborne accoustics, Can anybody help me on the IIC(Impact Isolation Class)study on SPF

Thanks

Be sure to compare the “Closed Cell” foam and “Open Cell” foam if you are planning on sound attenuation. Also consider the value of an air gap so you don’t create a rigid structure which passes sound thru the entire assembly. Some assemblies include both a Open Cell foam layer and a traditional fiberglass layer for maximum effect. Stay quiet.

Gary can you expand on using Open and fiberglass for sound?

Great Post, Thank you for giving such an informative article! Must read related Batt Insulation

Most Welcome. Hope to provide you with such informative content in the future too.

As a relied on Spray Foam Insulation Contractor in Toronto, Kitchener, Brampton in addition to Mississauga, we specialize inside the application of premium spray foam insulation. Our professional technicians use contemporary systems and techniques to create an unbroken thermal barrier in your home. Spray foam insulation bureaucracy a durable and hermetic seal, preventing warmth loss, air leakage, and moisture infiltration. This resulted in advanced energy efficiency, decreased noise transmission, and more suitable indoor consolation.

Outstanding job on the insulation project! The team was efficient, friendly, and delivered excellent results.